Incorporating Glucanobacter Xylinus Cellulose into Bacillus Cereus Poly-3-hydroxybutyrate in Order to Synthesize Biopolymer Composites with Novel Properties

Eustace Fernando[1], University of Westminster

Abstract

This investigation was focused on producing novel biodegradable polymer composites of bacterial origin using Glucanobacter xylinus cellulose and Bacillus cereus poly-3-hydroxybutyrate as component polymers. The possibility of incorporating an acetylated cellulose fibre fraction of plant origin to reinforce a poly-3-hydroxybutyrate matrix was demonstrated in earlier studies by Zini et al., 2007. This investigation, however, utilised cellulose of bacterial origin and cellulose surface modification by polyethylene glycol dicarboxylic acid esterification, assuming that a good level of compatibility can be achieved at the interface of two biopolymers.

Both component polymers were produced in sufficient quantities using shake flask batch fermentations of Glucanobacter xylinus and Bacillus cereus SPV. A dicarboxylic acid of polyethylene glycol (PEG) was used in an esterification reaction to chemically modify cellulose fibre surfaces. A solvent casting method was employed to deposit a uniform poly-3-hydroxybutyrate layer on modified cellulose. Mechanical properties of the composites were assessed using a constant load extensiometer.

Biopolymer composites produced using surface modified cellulose were compatible at the polymer interface and showed no indication of disintegration. Uni-axial tensile testing of composite material indicated plastic deformation properties and more ductile behaviour compared to cellulose.

Keywords: Cellulose, poly-3-hydroxybutyrate, extensiometry, composite, rehydration.

Introduction

Petroleum-derived synthetic polymers such as polyethylene, polyvinyl chloride, nylon and polystyrene have gained considerable commercial importance because of their versatility, ease of manufacture and low cost (Ojumu et al., 2003). Many synthetic polymers possess useful chemical and physical properties and are highly resistant to chemical and photodegradation. Because of valuable physical properties such as thermoplasticity, high mechanical strength, thermoelasticity and resistance to chemical degradation, these polymers are widely used, produced in large quantities and constitute a large market (Ojumu et al., 2003). However, most synthetic polymers are resistant to natural recycling processes and hence, tend to accumulate in the biosphere over time causing a severe ecological impact (Satyanarayana, 2007). Therefore, there is considerable interest in the development of polymers which are biodegradable and biocompatible, but which retain valuable chemical and physical properties of conventional synthetic polymers to a greater extent. Cellulose and polyhydroxyalkanoates (PHAs) are two biopolymers that are currently under investigation as viable alternatives to synthetic polymers. Both polymers are biodegradable, biocompatible and possess valuable physical and chemical properties such as high crystallinity (cellulose), high mechanical strength, thermostability, thermoplastic/thermoelastic properties (PHAs); they are insoluble in water and many other solvents (Zini et al., 2007). Cellulose and PHAs differ significantly in terms of their chemical properties, polymer arrangement and fibre forming ability.

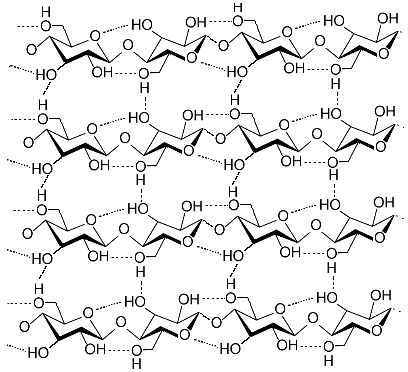

Cellulose, its Occurrence and Properties

Cellulose is the most ubiquitous polymer found in nature (Astley et al., 2001) and can either be of plant origin or of bacterial origin, of which the former is the most prominent type. It is a polymer of β 1-4 linked D glucose units condensed with glycosidic linkages and tends to arrange into a fibrous microstructure that present a hydrophilic outer surface due to many hydroxyl groups (figure 1) (Cybulska et al., 2009). It has a remarkably high tensile strength, crystallinity, is insoluble in water and many other solvents and possesses good water-retention properties when arranged into a fibrous structure. Dry amorphous cellulose becomes hydrated upon absorption of water (Astley et al., 2002).

Figure 1: β 1-4 linked D glucose units of cellulose and hydrogen bonding between cellulose chains (image adapted from http://en.wikipedia.org/wiki/File:Cellulose_strand.jpg)

It is more convenient to use bacterial cellulose in composite making with other polymers because bacterial cellulose lacks other associated polymeric components compared to plant cellulose (such as hemicellulose and lignin). Glucanobacter Xylinus extrudes cellulose ribbons into the growth medium and the exact biological function of these cellulose extrusions is poorly understood (Yoshino et al., 1996). Bacterial cellulose is always in its hydrated state and has much shorter fibril lengths compared to plant cellulose fibrils (Astley et al., 2002).

Poly-3-Hydroxybutyrate, its Occurrence and Properties

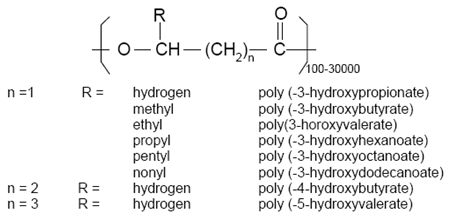

PHB is a biopolymer that belongs to a wider class of biodegradable and biocompatible polymers known as polyhydroxyalkanoates (PHAs).

Figure 2: The general formula of polyhydroxyalkanoates (image adapted from Ojumu et al., 2004; reproduced by kind permission of T. Ojumu)

Poly-3-hydroxybutyrate belongs to short chain length (SCL) type PHA and possesses physical and mechanical properties that closely resemble conventional synthetic plastics. Poly-3-hydroxybutyrate is fully biodegradable and biocompatible. It possesses a high tensile modulus and a Young's modulus (40MPa and 3.5GPa respectively) (Satyanarayana, 2007). The main challenge with regard to composite preparation is that the lack of compatibility at the polymer interface due to contrasting surface properties between cellulose and poly-3-hydroxybutyrate. Cellulose presents a highly hydrophilic surface in comparison to the largely hydrophobic surface presented by poly-3-hydroxybutyrate. Zini et al., 2007, demonstrated that surface modified cellulose fibres of plant origin (Jute and flax fibres) can be successfully employed as reinforcement fibres in poly-3-hydroxybutyrate matrices.

Aims of the Investigation

The study involved preparation of polymer composites using cellulose of bacterial origin and poly-3-hydroxybutyrate as component polymers. The objectives of the investigation were to achieve a satisfactory level of compatibility between the two component polymers at the polymer interface and to assess the mechanical properties of the resulting composite polymer at both dry and hydrated states. Therefore the hypothesis was that the surface modification reactions on bacterial cellulose surfaces would reduce its hydrophilic nature and allow a hydrophobic polymer matrix such as poly-3-hydroxybutyrate to be incorporated successfully.

Materials and Methods

Bacterial strains and maintenance

Glucanobacter xylinus (sub species-Sucrofermentans-ATCC 700178)

A sub-culture of Glucanobacter xylinus (strain-ATCC 700178) was maintained at 4°C in liquid YGC medium containing glucose-50.0g/L, yeast extract-5.0g/L and CaCO3-12.5g/L.

Bacillus cereus SPV

A stock culture of B.cereus SPV was prepared by adding 500μl of 30% glycerol to 500μl of previously prepared B.cereus SPV culture in nutrient broth medium. Sub-culture tubes were stored frozen at -28°C. Both bacterial strains were obtained from the University of Westminster culture collection.

Materials

All reagent grade chemicals used were obtained from Sigma Aldrich UK.

Production of cellulose using G.xylinus

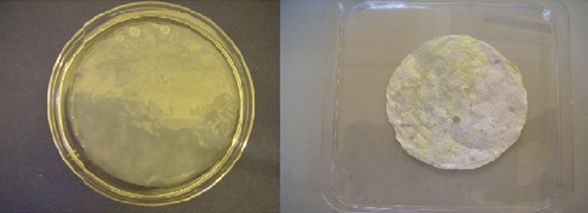

G.xylinus was grown in YGC medium containing glucose-50.0g/L, yeast extract-5.0g/L and CaCO3-12.5g/L. The pH of medium was adjusted to 6.6 using 1N HCl before inoculation. Batch cultures in flasks were incubated at 26°C for no more than five days under non agitating (static) conditions. No sampling was carried out and no agitation was applied in order to preserve the integrity of forming cellulose pellicles. Cellulose pellicles formed were harvested, boiled in a 1% (w/v) NaOH solution and stored in de-ionised water. The cellulose films were freeze dried and utilised in composite making.

Figure 3: Glucanobacter xylinus cellulose pellicles at native hydrated state (left) compared with freeze dried cellulose specimens (right)

Synthesis of Poly-3-Hydroxybutyrate using B.cereus SPV

B.cereus SPV was first grown to produce the seed culture (10% of the final culture volume) in 25g/L nutrient broth medium at 30°C, in flasks on a rotary platform agitated at 250RPM. The seed culture was inoculated into the production medium with following compositions (tables 1 and 2) after 16 hours of incubation. A preliminary fermentation run (3.5L culture volume) was carried out in order to investigate the growth curve and intracellular poly-3-hydroxybutyrate accumulation during different stages of the growth curve. A scaled-up fermentation run (16L) was carried out in order to produce the biopolymer in large quantities subsequently to be used in composite preparation. Fermentations were halted and cells were harvested by centrifugation at the transition between stationary and decline (death) phases (at 42 hours).

| Component | Concentration (g/L) |

|---|---|

| FeSO4 | 0.005 |

| (NH4)2SO4 | 2.0 |

| MnSO4.H2O | 0.003 |

| MgSO4.7H2O | 0.41 |

| K2HPO4* | 0.5 |

| CaCl2.2H2O* | 0.1 |

| CuSO4.5H2O | 0.0005 |

| ZnSO4.7H2O | 0.0005 |

| CoCl2 | 0.005 |

| Sucrose* | 20 |

| Yeast extract | 2.5 |

Table 1: Medium composition of preliminary fermentation of B.cereus SPV (components marked with asterisk were autoclaved and added separately)

| Component | Concentration (g/L) |

|---|---|

| (NH4)2HPO4 | 2.0 |

| K2HPO4 | 0.5 |

| Yeast extract | 2.5 |

| NaCl | 2.0 |

| Sucrose* | 2.0 |

| Trace element solution | 1mL/L |

Table 2: Medium composition of production fermentation of B.cereus SPV (components marked with asterisk were autoclaved and added separately)

[1L of the trace element solution consists of CaCl2-10g, CuSO4.5H2O- 5g, ZnSO4.7H2O- 5g, MnSO4.H2O- 3g, FeSO4.7H2O- 0.5g, MgSO4.7H2O- 0.21g, CoCl2- 0.21g, NaMoO4- 25µM]

Extraction of Poly-3-Hydroxybutyrate from Cell Pellet

Harvested cell pellet was freeze dried and finely ground to a powder form. The dry biomass powder was used in sodium hypochlorite/chloroform dispersion method as described by Hahn et al. (1994) to extract poly-3-hydroxybutyrate into a chloroform organic phase.

Figure 4: Bacillus cereus poly-3-hydroxybutyrate

Characterisation of intracellular poly-3-hydroxybutyrate production

Samples drawn in triplicates at 3-hour intervals during fermentation runs were used to obtain absorbance (A600) readings and pH variation throughout the fermentation run. The quantitative estimation of intracellular poly-3-hydroxybutyrate accumulation was carried out using crotonic acid assay as described by Law et al., 1960.

Synthesis of polyethylene glycol dicarboxylic acid

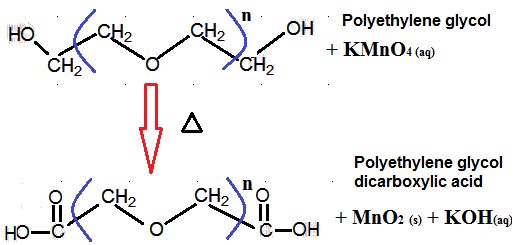

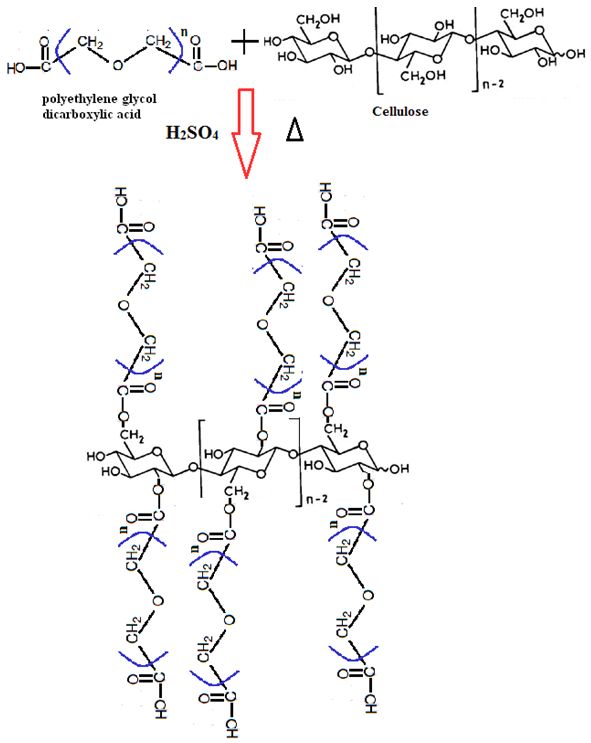

Concentrated solutions (~0.075M) of polyethylene glycol (approx. molar mass-4000g/mol) were prepared and converted to its dicarboxylic acid using potassium permanganate oxidation, as described by Ueyama et al., 1985 (scheme 1). The resulting dark brown manganese dioxide precipitate was separated by centrifugation.

Scheme 1: Oxidation of polyethylene glycol to polyethylene glycol dicarboxylic acid by the strong oxidising agent potassium permanganate

Solvent extraction of polyethylene glycol dicarboxylic acid

The supernatant was acidified with 2N HCl and added to 300mL of dichloromethane. The mixture was shaken vigorously in a glass bottle and allowed to settle into a bi-phasic state. The organic phase was separated, concentrated by rotary evaporation and polyethylene glycol dicarboxylic acid was precipitated by adding five volumes of ice cold diethyl ether.

Figure 5: Polyethylene glycol dicarboxylic acid synthesised by oxidation of polyethylene glycol (4000gmol-1)

Cellulose surface modification with polyethylene glycol dicarboxylic acid

An esterification method was used in order to modify cellulose fibre surfaces with PEG dicarboxylic acid (scheme 2). The surface esterification reactions of freeze-dried cellulose membrane were carried out using 0.033M PEG dicarboxylic acid (~4000g/mol approx molar mass) solution, in the presence of a concentrated sulphuric acid catalyst. The mixture was stirred, temperature maintained at 60°C and the reaction was allowed to take place for four hours.

Scheme 2: Esterification reaction between cellulose and polyethylene glycol dicarboxylic acid

Preparation of modified cellulose/poly-3-hydroxybutyrate composites

Composites of PEG-dicarboxylic acid modified cellulose copolymer and poly-3-hydroxybutyrate were prepared by a solvent casting method. Poly-3-hydroxybutyrate solutions of 0.06% (w/v) were prepared by dissolving 6mg of the polymer in chloroform to give a total solution volume of 10mL. The solution was cast onto 10mg samples of polyethylene glycol dicarboxylic acid modified cellulose membranes and chloroform was allowed to evaporate, leaving a uniform layer of poly-3-hydroxybutyrate deposited on modified cellulose.

Figure 6: Polyethylene glycol dicarboxylic acid modified cellulose membrane (left) and solvent casting of poly-3-hydroxybutyrate on modified cellulose

Uni-axial Tensile Testing of Composites

Sample preparation

Composite samples were cut out with a known uniform width of 2mm by using a pair of parallel mounted sharp blades with an approximate length of ~3cm. Composite samples that were to be tested at hydrated state were kept soaked in de-ionised water overnight before sample preparation.

Extensiometry

The mechanical properties of composite polymer samples were evaluated using a constant load extensiometer as described by Thompson (2001). If the specimens tested were at hydrated state, de-ionised water was added to sample chambers in order to maintain the hydrated state.

Figure 7: Composite polymer specimens undergoing uni-axial tensile testing at hydrated state

Results

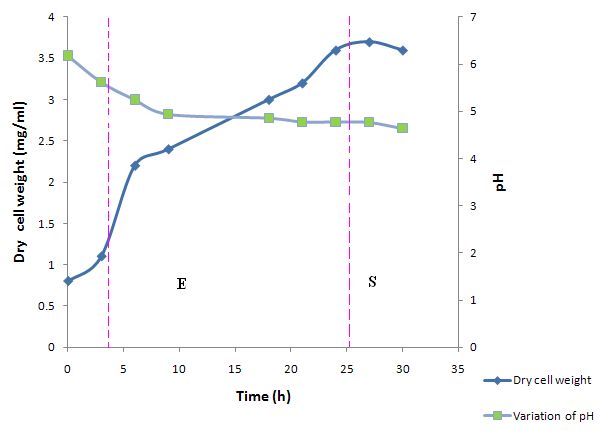

Bacillus cereus growth and intracellular polymer accumulation

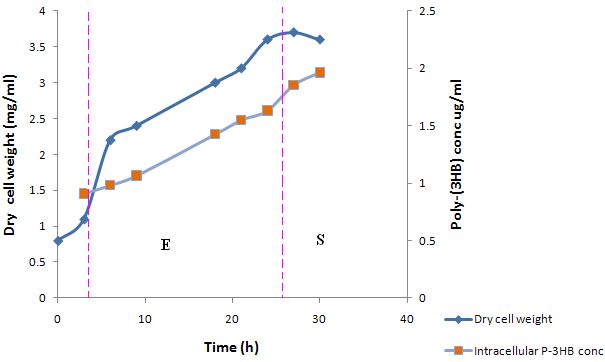

The variation of pH (Figure-8) suggests that the acidity of the growth medium is elevated as the culture reaches the stationary phase. This is most likely to have been caused by consumption of ammonium salts included in the medium by rapidly propagating B.cereus cells in order to fulfil its nitrogen needs. Moreover, this leads to inducing a nitrogen limiting environment for the organism where the carbon source is present in excess. This prevailing nutrient limiting (and excess carbon source) environment promotes intracellular poly-3-hydroxybutyrate accumulation. Moreover, this observation is consistent with the trend observed in figure 9 where highest intracellular polymer accumulation can be observed near the stationary phase (where the pH is low and a nitrogen limiting condition may prevail).

Figure 8: Bacillus Cereus growth curve compared to temporal pH variation in the growth medium (exponential and stationary phases of growth are indicated on the graph as E and S respectively)

Figure 9: Bacillus cereus growth compared with intracellular poly-3-hydroxybutyrate accumulation

Intracellular poly-3-hydroxybutyrate concentrations determined by crotonic acid assay indicate that the highest level of polymer accumulation is notable during the stationary phase of the growth curve. The yield coefficient for substrate/biomass (Yx/s) for the preliminary run was 0.0988 whereas the (Yx/s) for production run was 0.1. Intracellular poly-3-hydroxybutyrate accumulation during preliminary fermentation run was at 17.49% compared to 13% polymer accumulation during scaled up production run (polymer weight as a percentage of total dry biomass).

Biopolymer Composites of Polyethylene Glycol Dicarboxylic Acid Modified Cellulose and Poly-3-Hydroxybutyrate

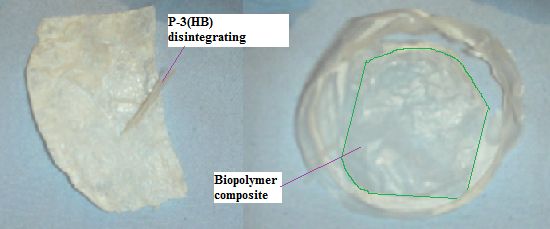

The biopolymer composites of PEG dicarboxylic acid modified cellulose copolymers and poly-3-hydroxybutyrate were compatible at the polymer interface. No indication of disintegration between the two polymer layers was observed. The same observation was noted in rehydrated samples of polymer composites (no disintegration occurs when cellulose fraction of the composite becomes rehydrated). Deposition of poly-3-hydroxybutyrate by solvent casting on the cellulose reinforcement fibre fraction was uniform. However, attempts to cast poly-3-hydroxybutyrate onto unmodified cellulose surfaces indicated poor compatibility at the polymer interface and subsequently resulted in disintegration of poly-3-hydroxybutyrate from cellulose surface (figure 10). This suggests that PEG dicarboxylic acid modification reaction has reduced the hydrophilic nature of cellulose surfaces and hence allowed to be incorporated into a hydrophobic poly-3-hydroxybutyrate polymer matrix.

Figure 10: The poly-3-hydroxybutyrate layer disintegrating from a surface unmodified cellulose surface (left) compared with the good compatibility of the two component polymers when surface modified cellulose is used (right). (Only the area marked in green contains the cellulose fibre fraction and hence, the composite material; the edges are residual poly-3-hydroxybutyrate from solvent casting)

Rehydration Properties of Bacterial Cellulose and its Composite Polymers

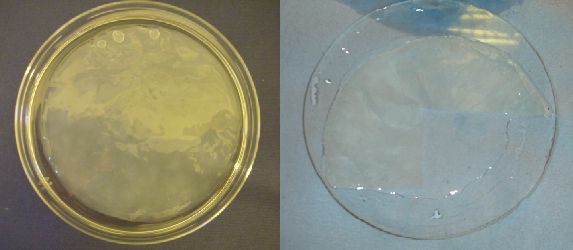

The native hydrated state of freeze dried specimens (and composite specimens containing a freeze dried cellulose fibre fraction) could be partially restored by soaking specimens in deionised water for at least 24 hours (figure 11).

Figure 11: The native hydrated state of G.xylinus cellulose (left) can only be partially restored in freeze dried specimens (right)

Uni-axial Tensile Testing of Composite Biopolymers

Engineering strain (εeng), relative length and True strain (εtrue) of tested samples were calculated.

εengis given by [Lt-L0/L0] = ΔL/ L0 where Lt and L0 are final and initial lengths respectively.

Therefore εeng= Linear displacement / Initial length

The relative length of samples undergoing uni-axial stress is given by

Ln [ΔL/L0] +1 = Ln [εeng] +1

However, the instantaneous strain of a material while undergoing uni-axial tensile stress is given by the true strain (εtrue) = Ln {(Lt-L0/L0) + 1}

Therefore, εtrue= Ln {εeng+ 1}

Uni-axial Tensile Testing of Composite Polymers at Dry State

For composite samples at dry state undergoing uni-axial tensile testing εeng, εtrueand relative length were calculated using linear displacement data and were plotted against time.

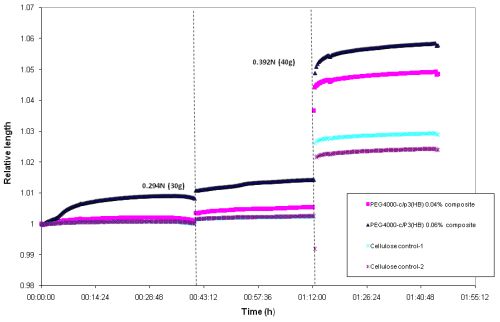

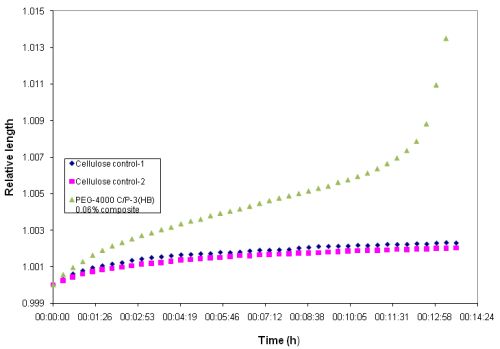

Figure 12: The temporal variation of relative length in modified cellulose and poly-3-hydroxybutyrate composite specimens undergoing uni-axial tensile testing at 0.294N (30g) and 0.392N (40g) loads

[Click on image for full-size version]

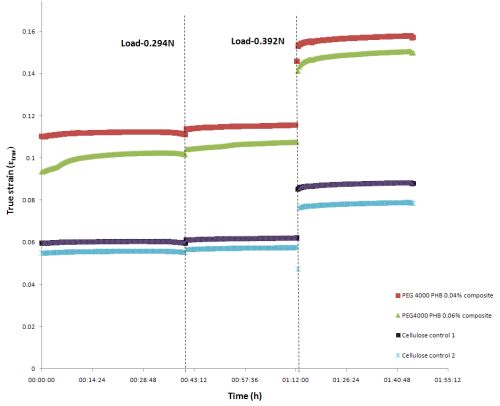

Figure 13: The variation of true strain (εtrue) in composite specimens undergoing uni-axial tensile testing under loads 0.294N and 0.392N

[Click on image for full-size version]

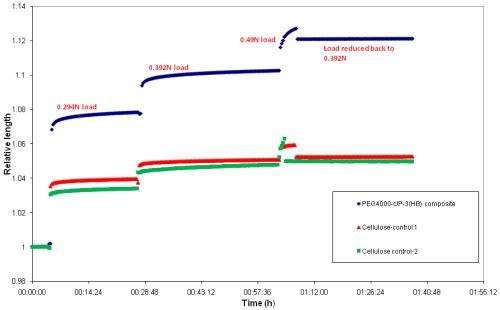

Figure 14: The composite material undergoing uni-axial tensile deformation under 0.294N, 0.392N and 0.49N indicates irreversible non-elastic deformation properties

[Click on image for full-size version]

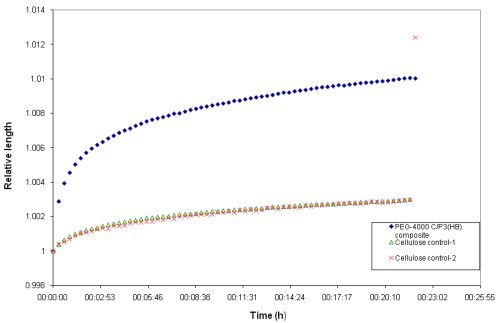

Figure 15: An amplified view of the region under 0.294N uni-axial stress indicates better ductile properties of the composite material compared to cellulose controls

[Click on image for full-size version]

The results from uni-axial tensile testing of biopolymer composite material at dry state indicate that the material undergoes irreversible deformation under increasing load and hence exhibits plastic deformation properties rather than elastic behaviour (figures 14, 15 and 16). This can be clearly observed in data represented in figure 14 where the material does not attain the original relative length when the load is reduced back to 0.392N from 0.49N but obtains an intermediate length between the two states. Moreover, the composite polymers can be regarded as more ductile compared to cellulose controls (figure 15) and hence the material can be considered more extensible and less brittle compared to cellulose homopolymer at dry state.

Figure 16: The variation of relative length under high (0.49N) load indicates that the composite specimen is undergoing 'necking', where the fracture of the specimen is imminent. The cellulose controls do not indicate the same mechanical behaviour; this suggests that the composites are comparatively more ductile and capable of undergoing plastic deformation

[Click on image for full-size version]

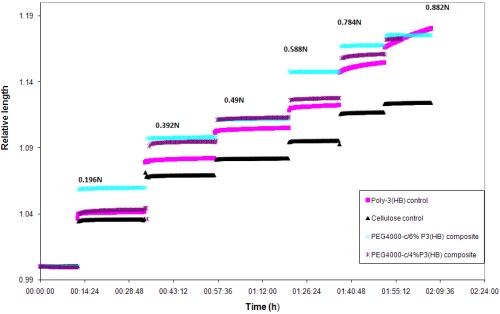

Uni-axial Tensile Testing of Composite Polymers at Hydrated State

Figure 17: The tensile behaviour of the composite material at hydrated state under loads ranging from 0.192N (20g) to 0.882N (90g)

[Click on image for full-size version]

Uni-axial tensile testing at hydrated state indicates that composites (and cellulose controls) indicate increased ductile behaviour compared to dry state. Even under a high load such as 0.882N, the material is capable of undergoing deformation while maintaining its integrity. However, the poly-3-hydroxybutyrate control indicates more fluid behaviour under high load (0.784N and 0.882N) suggesting that it is undergoing 'necking' and close to fracture (figure 17). The 'necking' effect can be clearly observed in composite polymer specimen at dry state under high (0.49N) stress (figure 16) where the relative length increases exponentially during 'necking' stage indicating the imminent fracture of the specimen. A significant increase in relative length in composite samples at hydrated state compared to samples at dry state can be observed (relative lengths 1.06 compared to 1.10 under 0.392N-figures 12 and 17). The same observation is notable regarding cellulose controls at dry state and hydrated state. This suggests that increased extensibility and more ductile behaviour observed in samples at hydrated state are almost exclusively given by the cellulose fibre fraction included in the composites. A possible explanation for this tensile behaviour could be the fact that cellulose fibre fractions in composite specimens are capable of trapping and retaining water molecules, resulting in more ductile and viscoelastic behaviour in hydrated specimens.

Discussion

This study demonstrates the possibility of reinforcing a poly-3-hydroxybutyrate matrix using a polyethylene glycol dicarboxylic acid modified cellulose fibre fraction. Reinforcing PHA matrices with cellulose fibre fractions in order to obtain novel properties is known to be problematic due to contrasting surface characteristics of the two component polymers (Zini et al., 2007). However, chemical modification of cellulose fibre surfaces allows achieving homogenous chemical properties at the interface of the two component polymers (Pommet et al., 2008). Chemical modifications on cellulose fibres elevate the level of compatibility of two component polymers. Therefore, chemical modifications on cellulose would enable the achievement of satisfactory levels of adhesion between the two component biopolymers at the interface. Two such chemical modification methods are acetylation of cellulose fibres of plant origin (Zini et al., 2007) and using coupling agents that induce hydrogen bonding such as 4,4-thiodiphenol (TDP) (Wong et al., 2003). The main reason for choosing cellulose of bacterial origin in this investigation is that it provides a reinforcement fibre matrix that is free from other accompanying polymers found in cellulose sources of plant origin, such as hemicellulose and lignin. Moreover, bacterial cellulose possesses quite different microstructural fibre arrangement compared to plant cellulose and has much shorter fibril lengths (Astley et al., 2001).

Polyethylene glycol dicarboxylic acid provides a much larger hydrophobic group when esterified with cellulose fibres compared to acetylated cellulose. Therefore, better compatibility (compared to acetylated cellulose) with hydrophopic polymers such as poly-3-hydroxybutyrate can be expected when used in composite materials.

PEG-di acid grafting reactions of cellulose membranes resulted in satisfactory level of compatibility between the two component biopolymers. Uni-axial tensile testing suggests that composite material exhibits intermediate mechanical behaviour when compared to its component polymers; cellulose and poly-3-hydroxybutyrate. The observed compatibility of two component biopolymers in the composite material is most probably due to hydrophobic interactions between the two polymers at the interface. However, it is necessary to assess the surface morphology of PEG dicarboxylic acid modified cellulose membranes and composite materials using techniques such as scanning electron microscopy (SEM) and Fourier Transform Infrared Spectroscopy (FTIR) in order to understand the exact type of interactions present at the interface of the composite materials.

Uni-axial tensile testing suggests that composites exhibit more ductile properties compared to cellulose controls (figure 15). It is also evident that composites undergo irreversible deformation during tensile testing and hence exhibit plasticity rather than elastic behaviour under high stress (figure 14). In longer timescales under lower but constant stress, these composite materials can be expected to exhibit viscoelastic 'creep' deformation properties. Moreover, the novel composites can be expected to possess intermediate mechanical properties compared to its component polymers. This assumption can be supported by evidence visible in composite samples at hydrated state undergoing uni-axial tensile testing (figure 17). The composite polymer material clearly indicates more ductile behaviour compared to cellulose control and suggests that it is less brittle compared to cellulose. Furthermore, poly-3-hydroxybutyrate control can be seen approaching 'necking' stage under high load (0.784N and 0.882N) where more fluid behaviour can be observed (this indicates that the fracture of the sample is imminent). Whereas composite samples do not exhibit the same behaviour as poly-3-hydroxybutyrate control under high loads (figure 16). Therefore this suggests that cellulose fraction included in the composite biopolymer elevates the load bearing capacity of the material when compared to poly-3-hydroxybutyrate component polymer.

Another advantage of using bacterial cellulose as the reinforcing fibre in biodegradable composite making is that bacterial cellulose is comprised of a short randomly oriented interwoven meshwork like nanofibril structure compared to much longer and bundle like fibre arrangement in plant cellulose (Brigid et al., 2009). Hence plant cellulose may provide good support against medial strain but limited support against lateral strain, whereas bacterial cellulose may provide support against multi-directional strain owing to its interwoven, meshwork-like structure.

Inherent water retention properties of freeze-dried cellulose samples can be considered as an interesting trait in terms of composite making with poly-3-hydroxybutyrate because this material may have the potential to be employed as scaffolds for tissue engineering purposes. The ability of the cellulose fraction to exist in a hydrated state while providing necessary mechanical support when coupled to a poly-3-hydroxybutyrate matrix, its microfibrillar, interwoven structure and biodegradable and biocompatible nature may allow such material to be used in place of carbon nanotubes as tissue engineering scaffolds. Moreover, such composites can be valuable in designing biodegradable microspheres for sustained release of various drugs due to dual (amphiphillic) properties of two component biopolymers utilised. The use of co-valently attached PEG chains on cellulose for surface modification can be expected to have minimal cytotoxic or immunogenic effect when used in medical applications (Kishida et al., 1990), since PEG attached (PEGylated) therapeutic proteins are already in medical use (Veronese et al., 2005). Cellulose of bacterial origin at hydrated state has its current medical applications in wound dressings and development of artificial blood vessels (Maneerung et al., 2008). Poly-3-hydroxybutyrate can potentially be used in bone tissue engineering and there is evidence indicating that poly-3-hydroxybutyrate supports osteogenesis (Phillip et al., 2009). The other major advantage of using Gram positive poly-3-hydroxybutyrate producers such as B.cereus is that the organism lacks an outer cell membrane and hence, immunogenic lipopolysaccharides (LPS) are not co-purified with PHAs during polymer isolation (Gram positive organisms lack LPS). LPS induce strong immunogenic reactions and therefore poly-3-hydroxybutyrate isolated from Gram negative bacteria is unsuitable for medical applications unless all LPS components are removed (Valappil et al., 2007).

Both component biopolymers utilised to produce composites in the investigation are fully biodegradable, non toxic and do not accumulate in eco-systems. Natural degradation of cellulose component in soil may be slower compared to degradation of poly-3-hydroxybutyrate due to slow action of cellulase enzymes (Ghose, 1987; Pommet et al., 2008). Bacterial cellulose exhibits higher degree of crystallinity compared to plant cellulose and hence can be comparatively more resistant to microbial degradation in soil (Wan et al., 2009). Modelli et al., 2003, reported that plant cellulose fibres (flax) modified with acetylation reactions are more resistant to biodegradation in soil compared to unmodified cellulose.

Concluding Remarks and Future Work

The results of the investigation indicate that poly-3-hydroxybutyrate matrices can be successfully reinforced with chemically modified cellulose of bacterial origin, in order to obtain novel mechanical and physical properties. The composites indicate a satisfactory level of integrity and compatibility at the interface at dry state, during tensile testing and after rehydration. Uni-axial tensile testing of the material suggests that mechanical properties differ from its component polymers and indicate more ductile behaviour. Water retention properties given by the cellulose fibre fraction further alter the properties of the material at hydrated state by increasing the ductile behaviour. By considering properties of the material it can be denoted that this material may have the potential to be considered as a possible candidate to develop scaffolds for tissue engineering purposes.

Furthering of the investigation would ideally include characterising the surface morphology of the material (by SEM imaging and FTIR spectroscopy), understanding the types of interactions present at the interface of the two component biopolymers and assessing biodegradation of the material in soil.

Acknowledgements

I would like to extend my gratitude for the help I received during the investigation to:

- Dr Stuart Thompson – Project supervisor;

- Dr Ipsita Roy – Bacillus cereus SPV fermentations;

- Azharul Islam (lab-C6.06) – YGC medium composition for Glucanobacter xylinus culture;

- Everest Akaraonye (lab-C6.03) - Optimised media compositions for Bacillus cereus SPV fermentations.

List of Figures

Figure 1: Chemical structure of cellulose and formation of hydrogen bonds

[Source: http://en.wikipedia.org/wiki/Cellulose]

Figure 2: General formula for Polyhydroxyalkanoates (PHA)

[Source: Ojumu et al., (2004), African Journal of Biotechnology, 3 (1), 18-24]

Figure 3: G.xylinus cellulose at hydrated state compared to freeze dried cellulose

Figure 4: Poly-3-hydroxybutyrate (PHB) isolated from B.cereus fermentations

Figure 5: PEG-di-acid isolated from PEG oxidation

Figure 6: A PEG grafted cellulose membrane and solvent casting of PHB on modified cellulose

Figure 7: Uni-axial tensile testing using an extensiometer

Figure 8: B.cereus growth and the variation of pH during the fermentation run as a function of time

Figure 9: B.cereus growth and the intracellular accumulation of PHB during the fermentation run as a function of time

Figure 10: Solvent casting of PHB onto surface unmodified cellulose compared to PEG grafted cellulose

Figure 11: The native hydrated state of G.xylinus cellulose compared to partially restored hydrated state of cellulose co-polymer/PHB composite material

Figure 12: The variation of relative length as a function of time in composite material at dry state undergoing uni-axial stress

Figure 13: The variation of true strain (εtrue) as a function of time

Figure 14: The variation of relative length as a function of time under various loads indicating non elastic but plastic deformation of composite biopolymer material

Figure 15: An amplified view of the region under 0.294N load, indicating an increased ductile behaviour of the composite material compared to cellulose controls

Figure 16: A plot of relative length as a function of time at an instance where the composite polymer material indicating 'necking' effect.

Figure 17: The variation of relative length as a function of time in composite materials at hydrated state, undergoing uni-axial stress under increasing loads

List of Schemes

Scheme 1: Potassium permanganate oxidation of poly ethylene glycol (PEG)

Scheme 2: Esterification of PEG-di-acid with cellulose

List of Tables

Table 1: Bacillus cereus growth medium (preliminary fermentation run)

Table 2: Bacillus cereus growth medium (production fermentation run)

Notes

[1] Eustace Fernando studied Biotechnology at the University of Westminster and recently started a PhD in Bio-electrochemisty at the same university.

References

Astley, O. M., E. Chanliaud, M. Donald and M. J. Gidley (2001), 'Structure of Acetobacter cellulose composites in the hydrated state', International Journal of Biological Macromolecules, 29, 193–2 02

Astley, O .M., E. Chanliaud, M. Donald and M .J. Gidley (2003),'Tensile deformation of bacterial cellulose composites', International Journal of Biological Macromolecules, 32, 28-35

Brigid, A., D. McKenna, J. B. Wehr, M. J. Gidley and N. W. Menzies (2009), 'Mechanical and structural properties of native and alkali treated bacterial cellulose produced by Gluconacetobacter xylinus strain ATCC 53524', Cellulose, 16, 1047–5 5

Chanliaud, E., K. M. Burrrows, G. Jeronimidis and M. J. Gidley (2002), 'Mechanical properties of primary plant cell wall analogues', Planta, 215, 989–9 6

Cybulska, J., E. Vanstreels, T. Q. Ho, C. M. Courtin and V. Craeyveld (2010), 'Mechanical characteristics of artificial cell walls', Journal of Food Engineering 96, 287–9 4

Ghose, T. K. (1987), 'Measurement of cellulase activities', Journal of Pure and Applied Chemistry, 59 (2), 257-68

Hahn, K. S., K. Y. Chang, B. Kim and N. Chang (1994), 'Optimization of microbial Poly(3-hydroxybutyrate) recovery using dispersions of Sodium hypochlorite solution and Chloroform', Biotechnology and Bioengineering, 44, 256-61

Kishida, A., K. Mishima, E. Corretge, H. Konishi and Y. Ikada(1992), 'Interactions of poly(ethylene glycol)-grafted cellulose membranes with proteins and platelets', Biomaterials, 13 (2), 339-51

Law, J. H. and R. A. Slepecky (1960), 'Assay of Poly-3-hydroxybutyric acid', Journal of Biological Chemistry, 82, 33-36

Maneerung, T., S. Tokura and R. Rujiravanit (2008), 'Impregnation of silver nanoparticles into bacterial cellulose for antimicrobial wound dressing', Carbohydrate Polymers, 72, 43–51

Modelli, A., R. Rondinelli and J. Scandola Mergaert (2004), 'Biodegradation of Chemically Modified Flax Fibers in Soil and in Vitro with Selected Bacteria', Biomacromolecules, 5, 596-602

Ojumu, T. V., J. Yu and B.O. Solomon(2004), 'Production of Polyhydroxyalkanoates, a bacterial biodegradable polymer', African Journal of Biotechnology, 3 (1), 18-24

Phillip, S., S. Sengupta, T. Keshavarz and I. Roy (2009), 'Effect of Impeller Speed and pH on the Production of Poly(3-hydroxybutyrate) Using Bacillus cereus SPV', Biomacromolecules, 10 (4), 691–99

Pommet, M., J. Juntaro, Y. Jerry, Y. Heng and F. Lee (2008), 'Surface modification of natural fibers using bacteria: Depositing bacterial cellulose onto natural fibers to create hierarchical fiber reinforced nanocomposites', Biomacromolecules, 9 (6), 1643-651

Quillaguamán, J., T. Doan-Van, J. Martin, E. Akaraonye and R. Hatti-Kaul (2008), 'Poly(3-hydroxybutyrate) production by Halomonas boliviensis in fed-batch culture', Applied Microbiology and Biotechnology, 78, 227–3 2

Satyanarayana, K.G. (2007), 'Biodegradable composites based on lignocellulosic fibres', International journal of advanced materials and composites, 83, 12-24

Thompson, D.S. (2001), 'Extensiometric determination of rheological properties of the epidermis of growing tomato fruit', Journal of Experimental Botany, 52 (359), 1291-301

Ueyema, N., M. Nakata and A. Nakamura (1985), 'A Poly(oxyethylene) supported Cys-Pro-Leu-Cys/Fe(II) complex as a Rubredoxin model: Protection of Fe-Cys coordination from hydrolysis in aqueous solution', Polymer journal, 17 (5), 721-27

Veronese, F. M. and G. Pasut (2005), 'PEGylation, successful approach to drug delivery', Drug discovery today 10, 1451-58

Valappli, S. P., S. K. Misra, A. R. Boccaccini, T. Keshavarz, C. Bucke and I. Roy (2007), 'Large-scale production and efficient recovery of PHB with desirable material properties, from the newly characterized Bacillus cereus SPV', Journal of Biotechnology, 132, 251–5 8

Wan, Y. Z., H. Luo, H. Liang, L. Huang and X.L. Li(2009), 'Mechanical, moisture absorption, and biodegradation behaviours of bacterial cellulose fibre-reinforced starch biocomposites', Composites Science and Technology, 69, 1212–1 7

Wong, S., R. Shanks and A. Hodzic (2004), 'Interfacial improvements in poly(3-hydroxybutyrate)-flax fibre composites with hydrogen bonding additives', Composites Science and Technology, 64, 1321–3 0

Yoshino, T. and T. Asakura (1996), 'Cellulose production by Acetobacter pasteurianus on silicone membrane', Journal of Fermentation and Bioengineering 81 (1): 32-36

Zini, E., M. Letizia, I. Noda and M. Scandola (2007), 'Bio-composite of bacterial poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) reinforced with vegetable fibers', Composites Science and Technology, 67, 2085–9 4

To cite this paper please use the following details: Fernando, E. (2011), 'Incorporating Glucanobacter Xylinus Cellulose into Bacillus Cereus Poly-3-hydroxybutyrate in Order to Synthesize Biopolymer Composites with Novel Properties', Reinvention: a Journal of Undergraduate Research, Volume 4, Issue 1, http://www.warwick.ac.uk/go/reinventionjournal/archive/volume4issue1/fernando. Date accessed [insert date]. If you cite this article or use it in any teaching or other related activities please let us know by e-mailing us at Reinventionjournal at warwick dot ac dot uk.