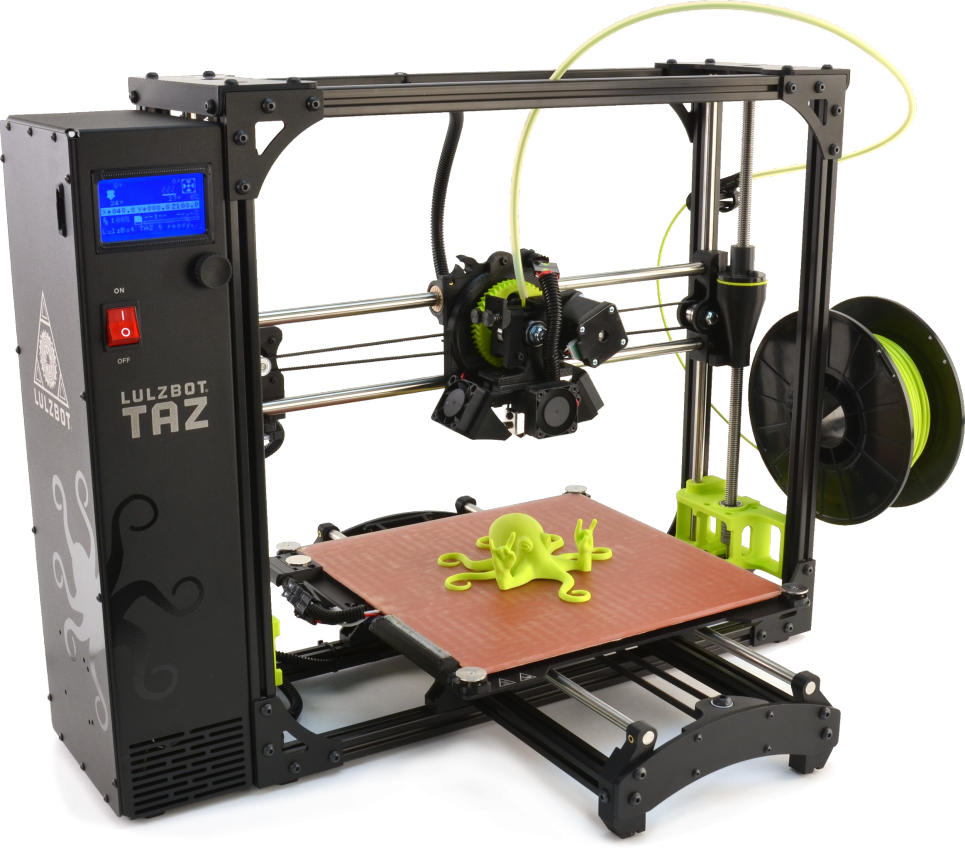

3D printing

The Lulzbot Taz 6 is a Fusion Deposition Modelling (FDM) 3D printer which uses layers of hot plastic to build up complex three-dimension shapes, up to a maximum size of 250x250x280mm. The printer is fitted with a dual extrusion head, allowing two materials to be printed simultaneously. In normal operation, this allows supports to be printed in a dissolvable or easily removable material, to prevent damage to the surface of the final piece. The second head can also be configured to print a second, non-support material, allowing for prints with a flexible or clear second material.

Specification:

| Print Area: | 280 mm x 280 mm x 250 mm |

| Print Volume: | 19,600 cm3 |

| Top Print Speed: | 200 mm/sec |

| Average Print Speed: | 30 - 50 mm/sec |

| Resolution (X-Y): | 0.1 mm |

| Minimum Layer Thickness: | 0.05 mm |

| Nozzle Diameter: | 0.5 mm |

| Maximum Hot End Temperature: | 300 °C |

| Maximum Bed Temperature: | 120 °C |

| Filament Diameter: | 2.85 mm |

Materials Carried:

PLA (Polylactic Acid):

A durable, easy to print filament, excellent for high detail or small prints. Due to a low shrinkage factor PLA doesn’t deform on cooling. PLA is also a biodegradable plastic made from renewable natural sources.

ABS (Acrylonitrile Butadiene Styrene):

ABS is a strong and impact-resistant filament ideal for 3D printing of object which will undergo high-mechanical strain. Note: Highly soluble in acetone and other similarly polar solvents.

PVA (Polyvinyl Alcohol):

PVA filament is used as a soluble support material for printing pieces with large overhangs. Easily soluble in water, with excellent adhesion to a variety of commonly used 3D printing plastics (such as ABS and PLA) makes PVA excellent for this task in dual extrusion printing.

Other Materials:

A wide range of filaments are available and can be used for specialist applications, these include flexible, transparent and more durable plastics. If you require these for an application, they can be ordered.

Creating a Model for Printing:

Any 3D CAD program (Such as Solidworks or Fusion 360) can be used to design a model for printing. Models should then be submitted in .STL format with a short description of what it is to be used for, and how high-quality a part is required.