WMG News

WMG Professor leads next phase of key research project

In 2023, WMG at the University of Warwick, received a share of £19 million from the Faraday InstitutionLink opens in a new window - the UK’s flagship institute for electrochemical energy storage research.

The funding was allocated to four key battery research projects aimed at delivering an impact for the UK. These existing projects across three different research areas - next generation cathode materials, electrode manufacturing and sodium-ion batteries - have been reshaped to focus on the areas with the greatest potential for success.

WMG took a key role in two of the four, reshaped projects entitled FutureCat and Nextrode. FutureCat is now entering its second phase with Louis Piper, WMG’s Professor of Battery Innovation, appointed as the new Principal Investigator (PI).

WMG took a key role in two of the four, reshaped projects entitled FutureCat and Nextrode. FutureCat is now entering its second phase with Louis Piper, WMG’s Professor of Battery Innovation, appointed as the new Principal Investigator (PI).

The battery cathode research project, focuses on understanding novel redox processes as a route to stabilise both high capacity, high performance, nickel rich and emerging cathodes and scalable designer morphologies. The next phase of the project will build on its success in developing reliable, scalable routes to deliver a longer lifetime, high-energy/power cathodes, essential for electric vehicles.

Professor Louis Piper explains: "Professor Cussen's leadership on FutureCat has resulted in significant advancements in Ni-rich cathodes. We are looking forward to continuing the pace of Ni-rich cathode innovation and development in phase II of the project. I am pleased that she will still work closely with the team."

James Gaade, Research Programme Director, commented: “We extend enormous thanks to Professor Serena Cussen for her engaging and collaborative leadership of the FutureCat project since its inception in 2019. In Professor Louis Piper the project has an accomplished research leader to take over the reins. WMG, University of Warwick has always been a key university partner for the Faraday Institution and is currently a member of five of our cross-disciplinary, multi-university battery research projects. We’re delighted to see the University becoming project lead for the first time.”

Professor Serena Cussen, former Principal Investigator of FutureCat, commented: “It has been the greatest privilege to lead the UK Faraday Institution's consortium on next-generation cathodes, FutureCat, as principal investigator since its inception in 2019.

“At the heart of our success has been a shared research vision and a culture of collaboration, which has seen our consortium deliver deep scientific insights on next-generation cathode discovery, development and scale-up as well as exciting partnerships with industry colleagues.

“While I am sad to leave the role of PI of FutureCat, I am delighted to see my friend and colleague Professor Louis Piper take over the leadership of this fantastic project. I have no doubt this is a project which will continue to go from strength-to-strength, and I look forward to collaborating with the FutureCat family of researchers.

Read more about FutureCat here: https://futurecat.ac.uk/

Professor David Greenwood on UK Gigafactory announcement from TATA Sons/JLR

Reactive statement from Professor David Greenwood, CEO of the High Value Manufacturing Catapult and Director of Industrial Engagement at WMG at the University of Warwick

“This is fantastic news and secures the future of our UK auto industry which would otherwise have been lost by 2035. Furthermore, this secures the supply chain meaning we’ve kept those jobs for everyone across the country.

“This is fantastic news and secures the future of our UK auto industry which would otherwise have been lost by 2035. Furthermore, this secures the supply chain meaning we’ve kept those jobs for everyone across the country.

“This announcement means that the UK is now above “critical mass” for supply chain companies and therefore sets the UK up to be an attractive place for businesses in the supply chain to invest to supply upstream and downstream materials needed for electric vehicle production. As one of the UK’s biggest academic institutions working in the area of battery and electric vehicle innovation, this is great news for all 250 of our researchers – we will now see the results of our work used in UK based industries and benefiting UK taxpayers rather than being exploited by competitors abroad.

“This is the culmination six years work here at Warwick Manufacturing Group - we helped the UK government set up the Faraday Battery Challenge which was a key part of the then Government’s industrial strategy. That investment has now borne fruit. Clearly, we now need to define our future vision and strategy as the global industrial landscape evolves at breakneck speed.

“This means the Prime Minister has realised he must provide sufficient investment to ensure the country is a competitive runner in the global race to dominate the markets created by the massive green transition needed to avert climate catastrophe.”

Battery recycling

Researchers at the University of Warwick estimate that by 2040 339,000 tonnes of batteries are expected to reach the end of their life in the UK alone.

Prof David Greenwood adds: “While we are busy building all these electric cars, we also need to think about what happens at the end of their useful life. Batteries contain significant quantities of materials which are costly to extract and refine and which could be hazardous to the environment if improperly disposed of. Investment is needed to create suitable recycling facilities in the UK within the next few years, and beyond that further research is needed to allow economic recovery of much greater proportions of the battery material. In doing so we will protect the environment, secure valuable raw materials, and reduce the cost of transport.”

Gigafactory FAQs

What is a gigafactory?

A gigafactory is a large factory that produces large numbers of batteries for electric vehicles. Tesla has pioneered the concept in the US, with six factories so far to produce batteries for their cars.

Why do we need one?

In order to a compete internationally and help preserve the UK automotive industry battery production needs to be scaled up rapidly across both the UK and Europe. This situation is exacerbated by tariffs due to be imposed across the UK and EU unless a certain proportion of a car is produced in one of those jurisdictions.

As an EV battery makes up around half of a vehicle’s weight it is crucial the UK vastly scales up battery production. Gigafactories are the most efficient way to do this.

How are electric car batteries made?

EV batteries come in lots of different shapes and sizes but are all made up of many battery cells put together to form a battery pack.

To make a battery, we take electrochemically active materials, like graphite, nickel manganese, cobalt and lithium, and make powders from them. These powders are mixed with solvents and adhesives, then coated onto metal (aluminium or copper) foils which are then packaged together inside cells.

This is a very precise process – otherwise the quality of the battery is impacted. At WMG, around 20 battery cells per day can be produced. At a gigafactory, production would be closer to 20 cells per second.

How are batteries recycled?

To recycle batteries, fire is used to recover most of the metals. Water can then be used to get further metals that can’t be reached using heat alone. There are still difficulties however in recycling lithium or graphite, which make up a large percentage of the metals in the batteries themselves.

With 11 million tonnes of lithium-ion batteries expected to need recycling by 2030, the need to build domestic capacity to recycle them is greater than ever.

Pushing the limits of battery research with nickel-rich chemistries

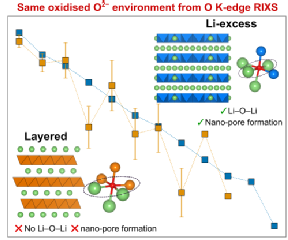

New research has shown that understanding how oxygen participates in energy storage is critical for developing higher energy density batteries, in a new paper published by experts at WMG, at the University of Warwick.

paper published by experts at WMG, at the University of Warwick.

Using advanced X-ray techniques, researchers at WMG, together with the Faraday Institution's FutureCat consortium, have obtained new insights into the oxygen redox activity in conventional ni-rich cathodes, which will help to deliver improved electric vehicle performance.

Range anxiety is a key concern of many potential EV buyers, but range is steadily improving as battery technology and research evolves. The Faraday Institution’s Next Generation Lithium-Ion Cathode Materials project, FutureCat, aims to develop understanding of existing and newly discovered cathode chemistries to deliver improved EV performance, whilst considering sustainability.

Professor Louis Piper, from WMG at the University of Warwick, who led the research explained: “Transitioning to electrification requires integrating advanced materials science into battery processing to develop cheaper, safer, faster and better batteries, which is the focus of our research.”

The battery field is moving to increasing nickel contents in cathodes to meet the Government’s stringent EV 2030+ targets. These roadmaps assume successful strategies in material development to allow cathodes like W-LNO to operate at high voltages without degrading. This work provides the platform towards realising that goal by better understand the redox mechanisms (i.e., the reactions that enable charging/discharging the battery) at high voltage operation.

The study employed advanced x-ray characterisation techniques at the Diamond Light Source in Oxford and at WMG. The team at WMG utilised novel in-house x-ray absorption spectroscopy which enabled researchers to look at the electrode redox process of the battery cathodes after careful disassembly. Researchers were surprised to find that the oxidised oxygen species had the same characteristics as another group of Li-ion battery cathodes, Li-excess transition metal oxides. Reconciling how the same oxidised oxygen environment exists in both conventional and Li-excess cathodes is critical for unlocking how to develop the next generation of cathodes.

Professor Piper adds: “This work highlights how large-scale collaborative fundamental studies are needed even for supposedly ‘known’ systems.”

WMG will be continuing with further studies in this field, supported by the Faraday Institution, for the benefit of cathode battery manufacturers.

A link to the published article can be found here:

https://journals.aps.org/prxenergy/pdf/10.1103/PRXEnergy.2.013005

EV-elocity project recognised at prestigious engineering awards

The EV-elocity project, involving engineers and researchers from WMG at the University of Warwick, has won a Collaborate to Innovate Award, from The Engineer magazine, in the Energy & Environment category.

The Awards celebrate the very best engineering collaborations and innovations across the UK.

EV-elocity is a research and development project looking at increasing the uptake of electric vehicles by helping consumers to monetise their investment using vehicle-to-grid (V2G) innovation.

With vehicle-to-grid (V2G) technology, electric vehicle (EV) batteries could store electricity - when there is an abundant supply - to power homes and businesses and to discharge it back to the national grid when it is most needed.

businesses and to discharge it back to the national grid when it is most needed.

Researchers at WMG developed a new model that quantified the degradation in the vehicle’s battery because of different EV charging strategies. The model highlighted that it was possible to manage the battery to mitigate much of the degradation and it was possible to even extend battery life through proper control and battery conditioning.

This enables better use of renewable energy, lower carbon footprint, less pressure on the grid and financial savings, which can help electric vehicle owners pay back their investment.

The EV-elocity project has deployed V2G chargers in a range of locations across England as part of large-scale trials to gain technical, customer and commercial insights on the emerging technology. It is also investigating if, and how, additional use from V2G charging may affect EV battery life.

Professor of Systems Modelling, James Marco, explains: “One of the unique aspects of EV-elocity, was the integration of EV technology with future energy infrastructure, such as vehicle-to-grid, to demonstrate at scale how novel methods of EV charging can provide multiple benefits for both the consumer and the environment.”

The project, led by Cenex, a not-for-profit consultancy specialising in delivery of low carbon vehicles and energy infrastructure projects also involves the Universities of Nottingham and Warwick; Leeds and Nottingham City Councils; and CrowdCharge, a platform that integrates and optimises smart electric vehicle charges.

EV-elocity is funded by the Department for Business Energy and Industrial Strategy (BEIS) and the Office for Zero Emission Vehicles (OZEV), in partnership with Innovate UK, part of UK Research and Innovation.

Read more about the award-wining EV-elocity project here: EV-elocity Project | vehicle-to-grid (V2G) innovation with electric vehicles

Warwick University will help Bolivia become the “energy cell of the world”

Historic agreement sees the university and Bolivia collaborate on lithium battery project and provide scholarships for Bolivian students

The University of Warwick is set to help Bolivia become a world leader in renewable energies and electric vehicles, thanks to a historic partnership on lithium battery research with the Bolivian Government.

The partnership, funded by the UK’s Foreign Commonwealth & Development Office (FCDO), will help develop lithium’s application as a power source in everything from electric cars to mobile phones.

Bolivia’s vast salt flats harbour an estimated 39 million tonnes of lithium reserve, positioning the country to be one of the world’s most important suppliers in the coming decades. The projects supports Bolivia’s ambition to provide 40% of the world’s supply of lithium by 2030. It will see Bolivia be at the forefront of lithium value chain, lead to higher paying employment and industry and a transition away from simple extraction and exploitation of raw materials.

Several master’s degree scholarships will also be offered to Bolivian students and the University’s WMG will link up with Yacimentos de Lito Bolivianos, Bolivia’s lithium mining institution in a multi-year research project to improve the understanding and possibilities for lithium battery technology.

Bolivia’s lithium mining institution in a multi-year research project to improve the understanding and possibilities for lithium battery technology.

David Rutley, Minister for the Americas and Caribbean at FCDO was present at the signing of the agreement and said: “This is a landmark partnership between Bolivia and Warwick – one of our great UK universities. This collaboration will help unlock the possibilities of battery technology in a new era of clean energy. The partnership will also address the drawbacks associated with using fresh water in the extraction process – making the industry more sustainable and less environmentally damaging.”

“This agreement demonstrates the potential for scientific and technological cooperation of our two great nations. It could help see Bolivia become the energy cell of the world.”

Professor Mike Shipman, University of Warwick’s Pro-Vice- Chancellor (International), said: “We are excited to be partnering with the Ministry of Hydrocarbons and Energies and Yacimentos de Litio Bolivanos. This collaboration will draw on the University’s extensive expertise in battery technologies and build new capabilities in Bolivia and help the global transition to sustainable power solutions through innovative research and training”.

Professor Robin Clark, Dean of WMG at the University of Warwick said: “This opportunity is one that will help ensure WMG stays at the forefront of global battery research and education. It has been a pleasure to share our work with our Bolivian partners and we hope that this is the start of a long and productive relationship.”

Professor Robin Clark, Dean of WMG at the University of Warwick said: “This opportunity is one that will help ensure WMG stays at the forefront of global battery research and education. It has been a pleasure to share our work with our Bolivian partners and we hope that this is the start of a long and productive relationship.”

Notes to editors:

For more information contact Tania Corbett, Media Relations Manager at Warwick University: tania.corbett@warwick.ac.ukLink opens in a new windowLink opens in a new window | Mob: +44 (0) 7824 540 727. General and out of hours press office number 02476 151 512

Interviews available in Spanish and English.

The research project between Warwick/WMG and Bolivia’s Yacimentos de Lito Bolivianos YLB will focus of synthesis and characterization of battery cathode materials derived from lithium extracted from the Salar de Uyuni. The partnerships will combine expertise on battery manufacturing and characterization between the two groups. Access to the sources of lithium supplies is critical for the development of active materials within Li-ion battery and requires the UK to develop strategic partnerships internationally.

WMG in landmark battery development partnership

Researchers at WMG at the University of Warwick, are part of a unique four-way partnership, with Addionics, technology innovation catalyst CPI and James Durrans Group, which will position the UK as a technology hub for global battery development.

James Durrans Group, which will position the UK as a technology hub for global battery development.

Project Constellation is an extension of Project STELLAR which focused on improving battery power and cycle life. Project Constellation takes the research to the next level addressing improvements to battery performance, which will in turn lower development and production costs.

The team at WMG will use its expertise in pilot scale electrode production, cell manufacturing and electrochemical testing to support and de-risk rapid technology screening and accelerate the route to market.

Farid Tariq Ph.D, CTO and Co-founder of Addionics, explains:" Constellation builds on the success of Stellar taking it beyond basic tests and towards industrially relevant scales. We are excited because it provides a strong integration piece of our technology with world leaders in coating and fabrication, and active material fabrication (WMG, CPI, James Durrans) that can show how our very smartly designed and structured current collectors can fit into a viable battery ecosystem and provide benefits from our technology. This is readily transferable knowledge and will push the creation of new methods to overcome modern limitations of batteries and fabrication."

Mark Copley, Chief Engineer in WMG at the University of Warwick’s Electrochemical Materials and Manufacturing team said: “WMG is delighted to be a partner in the CONSTELLATION consortium. Utilising our experience in scaling up new technologies, from lab to pilot line, we feel that we will be able to further the development of Addionics’ current collector technology whilst coupling in Durrans’ graphite and formulation developments, as derived by CPI.

“The project goals fit very well with the ideals of WMG, which is to work collaboratively with industry to deliver high-quality, applied, research and development. We look forward to the results that will be generated through this funded collaborative effort.

Project Constellation is a two year project, funded by the UK Government’s Faraday Institution’s Faraday Battery Challenge Round 5 Innovation.

About the partners

Addionics

Addionics is a next-generation battery technology company revolutionizing battery performance through its chemistry-agnostic Smart 3D Electrode architecture. The company’s scalable, cost-effective manufacturing process combined with its AI-based optimization software significantly improves the performance of any kind of chemistry, achieving batteries with higher energy density, faster charging, and longer lifetime, at low cost. With the mission to accelerate an electrified economy and decarbonized future, Addionics is unlocking the full potential and accelerating the electrification revolution through its drop-in solutions.

CPI

We take great ideas and inventions, and we make them a reality. Born in the North East of England in 2004, CPI is an independent deep tech innovation organisation and a founding member of the High Value Manufacturing Catapult.

We're a team of intelligent people using advances in science and technology to solve the biggest global challenges in healthcare and sustainability. Through our incredible people and innovation infrastructure, we collaborate with our partners in industry, academia, government, and the investment community to accelerate the development and commercialisation of innovative products.

Our work ranges from health technologies, advanced drug delivery systems, and medicines manufacturing innovations for multiple modalities including small molecules, biologics, and nucleic acids; to developing sustainable materials for energy storage and packaging, as well as novel food, feed, and nutraceuticals, that are all underpinned by digital technology. We turn the entrepreneurial spirit and radical thinking of our people and partners into incredible impact that makes our world a better place.

Let’s innovate together: uk-cpi.comLink opens in a new window

Connect with us: LinkedIn TwitterLink opens in a new window InstagramLink opens in a new window FacebookLink opens in a new window

James Durrans Group

Long established family owned manufacturing company (1863) based in Penistone near Sheffield but with manufacturing sites across the globe. We provide pro-active solutions to our customer needs. Experts in carbon processing and technology and the manufacture of heat resistant coatings and graphitic dispersions.

International accreditation for WMG’s Energy Innovation Centre

The Energy Innovation Centre (EIC) at WMG, University of Warwick has successfully achieved two key ISO Management Systems Standards (MSS).

The Energy Innovation Centre (EIC) at WMG, University of Warwick has successfully achieved two key ISO Management Systems Standards (MSS).

ISO Management Systems Standards set out requirements or guidance to help organisations manage policies and processes to achieve specific objectives and maintain high customer service. Each ISO has specific points of clarification.

The first MSS that the EIC was assessed against was ISO 9001 on Quality Management Systems. The audit covered the entire business operation within WMG’s battery research facilities, including the manufacture of battery cells and packs, testing of chemistries from degradation and performance through to full destructive testing.

The second standard ISO 14001 covers Environment Management Systems. This standard specifies the requirements for a sustainable management system that can be used to enhance environmental performance. This included a full assessment of how environmental risks are managed within the EIC.

The EIC was successful in achieving full certification of both standards.

Mark Amor-Segan, Chief Engineer based in the EIC at WMG, University of Warwick said: “We are one of the first university research groups to achieve this. This certification will align us with many of our industrial partners in terms of the fundamental principles of quality and environmental performance.

“Achieving this is a testament to the hard work from everyone within the EIC, and demonstrates our commitment to develop, implement and maintain an integrated quality and environmental management system (IMS) that meets the requirements of ISO 9001, ISO 14001 and our company, legal and other obligations.”

For a copy of the WMG Energy Innovation Centre IMS Combined Policy Statement contact: eic.support@warwick.ac.uk

The Energy Innovation Centre is a national facility, funded by the High Value Manufacturing Catapult (HVMC), for battery research across the R&D process from materials and electrochemistry through to application integration and recycling/re-use. The facilities support test, development and scale up of new battery chemistries from concept through to full proven traction batteries, produced in sufficient quantities for detailed industrial evaluation in target applications.

For more information or to arrange a tour of WMG’s facilities email wmgbusiness@warwick.ac.uk

WMG unveils the world’s first EV Thermal Management Testbed

WMG has unveiled a special Thermal Management Testbed, to allow holistic investigation of HVAC (Heating, Ventilation and Air Conditioning) and other vehicle sub-systems under real-world conditions.

WMG has unveiled a special Thermal Management Testbed, to allow holistic investigation of HVAC (Heating, Ventilation and Air Conditioning) and other vehicle sub-systems under real-world conditions.

The Testbed, which is a world-first, was funded by the High Value Manufacturing Catapult, and is located at the University of Warwick’s Wellesbourne campus. It is designed specifically to develop and evaluate efficient thermal management systems for electric vehicles; including cabin climate control; thermal management of energy storage and electric machines; and the impact on the overall performance of the vehicle.

Truong Quang Dinh, Associate Professor of Energy System Management and Control at WMG, explains: “Effective heating and cooling of vehicle sub-systems is indispensable to ensure safety, reliability and comfort. Our unique thermal management testbed integrates a highly flexible HVAC rig and a hybrid physical-virtual powertrain for the holistic investigation of thermal management systems and other vehicle sub-systems under real-world conditions. This enables real-time tests from vehicle components, sub-systems, to entire systems at lowest time, cost and effort.”

One project that will be exploring the capabilities of the new Thermal Testbed is Cit-E-Van, - a collaboration between WMG, CoolVan and GAH, funded by Innovate UK. Cit-E-Van will look to develop an energy efficient electric refrigerated vehicle with an optimised electric transport refrigeration unit and retrofit the electric propulsion system with advanced thermal-energy management features.

In the coming months WMG experts will be working with more industry partners to develop HVAC solutions.

For further information about the testbed or HVAC solutions in general contact Truong Quang Dinh at: t.dinh@warwick.ac.uk

Energy stored in electric car batteries could be used to power homes

With vehicle-to-grid (V2G) technology, electric vehicle (EV) batteries could store electricity - when there is an abundant supply - to power homes and businesses and discharge it back to the national grid when it is most needed.

businesses and discharge it back to the national grid when it is most needed.

This enables better use of renewable energy, lower carbon footprint, less pressure on the grid and financial savings, which can help electric vehicle owners pay back their investment.

During the course of this year, the EV-elocity project has been deploying V2G chargers in a range of locations across England to as part of large-scale trials to gain technical, customer and commercial insights on the emerging technology. It is also investigating if, and how, additional use from V2G charging may affect EV battery life.

The project, led by Cenex, a not-for-profit consultancy specialising in delivery of low carbon vehicles and energy infrastructure projects also involves the Universities of Nottingham and Warwick; Leeds and Nottingham City Councils; and CrowdCharge, a platform that integrates and optimises smart electric vehicle charges. EV-elocity is funded by the Department for Business Energy and Industrial Strategy (BEIS) and the Office for Zero Emission Vehicles (OZEV), in partnership with Innovate UK, part of UK Research and Innovation.

Chris Rimmer, Infrastructure Strategy Lead at Cenex, said: “After restarting the project in mid-2020, we are delighted to be testing V2G with such a range of sites and hardware. We’ll be working hard over the coming months to examine the cost, carbon and conditioning benefits of V2G, and publish our results as they become available.”

Professor James Marco, from WMG at the University of Warwick comments:

“A number of consumers and vehicle manufacturers are concerned that V2G will disproportionably reduce battery life, representing a potential barrier for widespread adoption of V2G and consumer acceptance. Here at WMG, University of Warwick, we are excited to be researching novel new methods of managing the V2G charging process not just to mitigate battery degradation, but to potentially use V2G to extend battery life.”

With V2G technology, EVs could help to support grid resilience when parked and plugged-in. Instead of installing huge and expensive community battery stores, an extensive network of EV batteries could be harnessed to absorb energy when renewable generation is plentiful and export it back to the grid during peak demand when carbon intensity is highest for a profit, making money back for users in the process.

With V2G technology, EVs could help to support grid resilience when parked and plugged-in. Instead of installing huge and expensive community battery stores, an extensive network of EV batteries could be harnessed to absorb energy when renewable generation is plentiful and export it back to the grid during peak demand when carbon intensity is highest for a profit, making money back for users in the process.

The project is installing multiple V2G charging demonstrators at sites owned by organisations -including city councils, universities and police forces - that employ large electric vehicle fleets. Latest data suggests that if the 5.3 million fleet vehicles on UK roads today were to switch to EV, it would save as much as 25 per cent of all UK transport emissions.

Dr Julie Waldron, Research Fellow at the University of Nottingham, who is studying user behaviour, said: “Company cars and vans tend to earn money while out on the road, but electric vehicles could also be a source of income when they’re parked up. We know cost is a major factor deterring mass adoption of electric vehicles, but if V2G charging helps EV owners get a quick return on their investment, it could make purchasing electric vehicles a much more attractive option to a bigger customer base.”

· With the biggest electric fleet of any local authority in England, Leeds City Council has installed 5 V2G chargers under the EV-elocity project

· The University of Nottingham, another user of EV fleets, has installed two V2G units on its main campus

· Cenex installed one V2G charger at Loughborough University Science and Enterprise Park, one charger at Worcestershire County Council and two chargers at West Midlands Police.

· University of Warwick installed three chargers on campus to be used by the Estates fleet

· Nottingham City Council, which also has a large electric vehicle fleet and a very ambitious target to become carbon neutral by 2028, is planning to install 40 units

Using data from V2G chargers and trackers in EV cars, and user behaviour analysis on the study, researchers are examining mobility patterns, EV charging requirements/trends, battery degradation, and electricity generation, storage and use.

“Understanding the patterns of vehicle usage will allow us to evaluate the best charging infrastructure required for EVs, for example the locations and type of charging points and plugs (which currently vary between car brands), compatibility with V2G, charging periods and energy demand, etc. This will enable us to rethink the system and inform the users’ decision-making process in order to maximise benefits for consumers and the planet.” Dr Waldron adds.

ENDS

10 NOVEMBER 2021

NOTES TO EDITORS

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/l1010256.jpg

Caption: A V2G charger on campus at the University of Warwick

Credit: EV-elocity

Caption: A V2G charger on campus at the University of Warwick

Credit: EV-elocity

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/l1010286.jpg

Caption: A V2G charger on campus at the University of Warwick

Credit: EV-elocity

Caption: A V2G charger on campus at the University of Warwick

Credit: EV-elocity

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/l1010293.jpg

Caption: A V2G charger on campus at the University of Warwick

Credit: EV-elocity

1. University of Nottingham

Researchers from the Transport, Mobility and Cities and the Building, Energy and Environment research groups are studying user behaviour in EV-elocity demonstrator trials. They have also developed a V2G case study that will be tested at the University Park Campus. The project fits in well with the University’s commitment to use innovative technologies to make its campuses smarter and more sustainable to enhance the user experience and reduce its carbon footprint. The campus’ infrastructures and services operate very much like those of a small town, so it is a great testbed for technology implementation prior to installation in real cities.

University Park campus uses different types of fleets, in terms of users, routines, parking location and dwell times. This behaviour data was analysed and correlated with other parameters such as routes and movement patterns, renewable energy availability on site, grid cost and grid energy carbon emissions to identify the most promising charging pattern and infrastructure to deliver financial and carbon savings, improve battery life and maximise local renewable energy consumption.

Under EV-elocity, two V2G units have been installed on University Park campus and will be collecting data until March 2022 to identify whether proposed usage delivers against the targets set.

https://www.ev-elocity.com/news/vehicle-to-grid-at-hallward-library-university-of-nottingham/

2. Cenex, Loughborough University Science and Enterprise Park

https://www.ev-elocity.com/news/the-uks-most-scenic-v2g-chargepoint-deployment/

3. Leeds City Council

https://www.ev-elocity.com/news/vehicle-to-grid-at-leeds-city-council/

Leeds has one of the largest public sector fleets of electric vehicles in the country and ambitions plans to continue its transition to a zero emission fleet as part of meeting a city-wide target to become the first net zero major city. This project is part of delivering on this ambition. There have been six V2G units installed in Leeds, one at our Parks & Countryside department headquarters at Farnley Hall and five at our Knowsthorpe Gate depot site. The chargers will be used by a range of different services vehicles across this sites with the Nissan Env-200’s utilised for the project having been fitted with telematics to capture data to feed into the projects assessment of the technology.

4. WMG University of Warwick

WMG is a world leading research and education group, transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes.

As an international role model for successful partnerships between academia and the private and public sectors, WMG develops advancements nationally and globally, in applied science, technology and engineering, to deliver real impact to economic growth, society and the environment.

WMG’s education programmes focus on lifelong learning of the brightest talent, from the WMG Academies for Young Engineers, degree apprenticeships, undergraduate and postgraduate, through to professional programmes.

An academic department of the University of Warwick, and a centre for the HVM Catapult, WMG was founded by the late Professor Lord Kumar Bhattacharyya in 1980 to help reinvigorate UK manufacturing and improve competitiveness through innovation and skills development.

5. Worcestershire County Council

One vehicle-to-grid charger was installed at the headquarters of Worcestershire County Council, County Hall, in their underground staff car park. The test vehicle a 2016 Nissan Leaf is used by the council as a pool car for staff to make visits in the local area.

6. West Midlands Police

Two vehicle-to-grid chargers were installed at the mezzanine car park of the West Midlands Police Head Quarters. These units will be used to charge (and discharge) two Nissan Leafs (2016) that are part of the non-emergency response fleet based at the site in central Birmingham. These vehicles are used as pool cars by staff to attend non-urgent appointments and enquiries in the city and the surrounding area.

About EV-elocity:

The Project EV-elocity is part of the Vehicle-to-Grid (V2G) competition, funded by the Department for Business Energy and Industrial Strategy (BEIS) and the Office for Zero Emission Vehicles (OZEV), in partnership with Innovate UK, part of UK Research and Innovation.

The 20 V2G projects (8 feasibility studies, 4 collaborative research and development projects, and 8 real-world V2G trial projects) receive funding of £30m to develop the business proposition and the core technology to support V2G deployment in the UK, including its demonstration with large scale trials.

The 20 projects involve more than 50 industrial partners and research organisations from both the Energy and Automotive sectors, making it the largest and most diverse V2G activity in the world, trialling more than 500 vehicles and V2G charger units across UK.

The V2G projects represent a significant step towards the transition to a low carbon transportation and a smart energy system. Allowing EVs to return energy to the Power Grid when parked and plugged-in will increase Grid resilience, allow for better exploitation of renewable sources and lower the cost of ownership for EV owners, leading to new business opportunities and clear advantages for EV users and energy consumers.

For further information please contact:

Alice Scott

Media Relations Manager - Science

University of Warwick

Tel: +44 (0) 7920531221

E-mail: alice.j.scott@warwick.ac.uk

Pioneering industry collaboration accelerates hydrogen refuelling innovation for HGVs

WMG is working with Midlands-based SME Hy-Met Limited and Logan Energy to deliver the Hydrogen Prototype Equipment for Refuelling (HyPER) project.

Together, the consortium will develop a next-generation hydrogen flowmeter for refuelling Heavy Goods Vehicles (HGVs). These will be used for hydrogen refuelling systems, and will be lightweight, smaller, more cost effective and more accurate than existing instruments.

refuelling systems, and will be lightweight, smaller, more cost effective and more accurate than existing instruments.

This follows recent funding from the UK Government’s Department of Transport zero emission road freight trials through Innovate UK. The project value totals around £170,000.

The new meter will also be easier to manufacture and maintain than current options on the market.

The project aims to reduce the cost of hydrogen refuelling and enable the wider adoption of hydrogen by transport fleets and other users.

Nishal Ramadas, co-founder and CEO of Hy-Met, said: “Since launching Hy-Met in January, we’ve been motoring ahead with our plans to help with the transition to net zero. With our innovative measurement platform, Hy-Met is combining our deep hardware and software expertise to tackle some of the complex measurement challenges facing the hydrogen sector.

“When building the consortium, we knew we needed partners with detailed knowledge of the requirements for hydrogen refuelling and advanced manufacturing and prototyping capabilities.

“Our choice of project partners was clear and we are very happy Logan Energy and WMG have joined us in tackling this refuelling challenge.”

Bill Ireland, Chief Executive at Logan Energy, said: “Using hydrogen to power lorries is one of the key steps towards helping Scotland and the UK tackle the climate emergency.

“Making the switch from burning diesel to using hydrogen will cut the amount of carbon dioxide and other harmful gases being pumped into the atmosphere.

“There are a number of advancements we need to take before hydrogen becomes commonplace on our roads and one of the crucial elements is making it cheap and easy to refuel.

“For nearly three decades Logan Energy has been at the forefront of developing new and innovative hydrogen technologies both here in the UK and abroad. This collaborative partnership with Hy-Met and WMG is another step towards helping the UK grow its capabilities within the hydrogen industry and the drive to net-zero.”

Dmitry Isakov, Assistant Professor at WMG, said: “Securing this funding from the Department of Transport through Innovate UK will help us to accelerate our work. Working alongside Logan Energy and Hy-Met will allow us all to combine our knowledge and expertise to develop an industry-leading hydrogen flowmeter.”