WMG News

WMG joins flagship electrification partnership

WMG at the University of Warwick, is part of a unique six-way partner collaborative research and development project led by Aston Martin.

Project ELEVATION has received £9m funding from the Advanced Propulsion Centre UK (APC) to supplement the research and development of Aston Martin’s in-house bespoke luxury battery electric vehicle platform.

Awarded following a competitive process, the government grant will support the development of Aston Martin’s luxury BEV platform and enable a route to net-zero, including investment in vehicle light weighting, a digital toolchain and electrification training.

Project ELEVATION is led by Aston Martin, and supported by the Manufacturing Technology Centre; Expert Tooling & Automation; Creative Composites; Fuzzy Logic Studio and WMG. The project will address the technical challenges of developing a lightweight, 800V traction battery pack and twin front electric drive unit (EDU) into a modular BEV platform with a bandwidth from supercar to SUV.

WMG’s role will focus on supporting the design, manufacture and life-cycle analysis (LCA) of the modular structural composite battery enclosure. Researchers in the composites group based in WMG's Materials Engineering Centre (MEC) will conduct materials evaluation and investigate automated high-volume composite manufacturing of hybrid structures using existing tooling and equipment to demonstrate attributes on early learning components. This knowledge will then be transferred to Creative Composites for manufacture of the project demonstrator components and provide LCA of the composite structure into the Manufacturing Technology Centre's holistic LCA model.

WMG’s role will focus on supporting the design, manufacture and life-cycle analysis (LCA) of the modular structural composite battery enclosure. Researchers in the composites group based in WMG's Materials Engineering Centre (MEC) will conduct materials evaluation and investigate automated high-volume composite manufacturing of hybrid structures using existing tooling and equipment to demonstrate attributes on early learning components. This knowledge will then be transferred to Creative Composites for manufacture of the project demonstrator components and provide LCA of the composite structure into the Manufacturing Technology Centre's holistic LCA model.

Roberto Fedeli, Group Chief Technology Officer of Aston Martin, said: “The award of funding from the APC is another major boost to our electrification strategy and constant strive for innovation. Providing further resources to explore the possibilities of our bespoke BEV platform, it will help achieve our ambition to be an in-house BEV technology leader in the ultra-luxury, high-performance segment. We look forward to progressing this project with our collaborative partners and thank the APC for their incredible support.”

Ian Constance, APC Chief Executive, said: “The 23rd round of our collaborative R&D competition coincides with the APC’s 10th anniversary. We’ve seen over £1.4 billion of investment into automotive projects since the APC was set up, and I am proud of the impact that we have made here in the UK. This latest announcement includes a diverse set of OEMs and suppliers that demonstrate the strength of UK automotive. They will further add to our portfolio of innovative projects and continue to drive the UK to deliver on its net zero ambition.”

Find out more about WMG’s composite light-weighting research here https://warwick.ac.uk/fac/sci/wmg/research/materials/acrc

Professor David Greenwood on UK Gigafactory announcement from TATA Sons/JLR

Reactive statement from Professor David Greenwood, CEO of the High Value Manufacturing Catapult and Director of Industrial Engagement at WMG at the University of Warwick

“This is fantastic news and secures the future of our UK auto industry which would otherwise have been lost by 2035. Furthermore, this secures the supply chain meaning we’ve kept those jobs for everyone across the country.

“This is fantastic news and secures the future of our UK auto industry which would otherwise have been lost by 2035. Furthermore, this secures the supply chain meaning we’ve kept those jobs for everyone across the country.

“This announcement means that the UK is now above “critical mass” for supply chain companies and therefore sets the UK up to be an attractive place for businesses in the supply chain to invest to supply upstream and downstream materials needed for electric vehicle production. As one of the UK’s biggest academic institutions working in the area of battery and electric vehicle innovation, this is great news for all 250 of our researchers – we will now see the results of our work used in UK based industries and benefiting UK taxpayers rather than being exploited by competitors abroad.

“This is the culmination six years work here at Warwick Manufacturing Group - we helped the UK government set up the Faraday Battery Challenge which was a key part of the then Government’s industrial strategy. That investment has now borne fruit. Clearly, we now need to define our future vision and strategy as the global industrial landscape evolves at breakneck speed.

“This means the Prime Minister has realised he must provide sufficient investment to ensure the country is a competitive runner in the global race to dominate the markets created by the massive green transition needed to avert climate catastrophe.”

Battery recycling

Researchers at the University of Warwick estimate that by 2040 339,000 tonnes of batteries are expected to reach the end of their life in the UK alone.

Prof David Greenwood adds: “While we are busy building all these electric cars, we also need to think about what happens at the end of their useful life. Batteries contain significant quantities of materials which are costly to extract and refine and which could be hazardous to the environment if improperly disposed of. Investment is needed to create suitable recycling facilities in the UK within the next few years, and beyond that further research is needed to allow economic recovery of much greater proportions of the battery material. In doing so we will protect the environment, secure valuable raw materials, and reduce the cost of transport.”

Gigafactory FAQs

What is a gigafactory?

A gigafactory is a large factory that produces large numbers of batteries for electric vehicles. Tesla has pioneered the concept in the US, with six factories so far to produce batteries for their cars.

Why do we need one?

In order to a compete internationally and help preserve the UK automotive industry battery production needs to be scaled up rapidly across both the UK and Europe. This situation is exacerbated by tariffs due to be imposed across the UK and EU unless a certain proportion of a car is produced in one of those jurisdictions.

As an EV battery makes up around half of a vehicle’s weight it is crucial the UK vastly scales up battery production. Gigafactories are the most efficient way to do this.

How are electric car batteries made?

EV batteries come in lots of different shapes and sizes but are all made up of many battery cells put together to form a battery pack.

To make a battery, we take electrochemically active materials, like graphite, nickel manganese, cobalt and lithium, and make powders from them. These powders are mixed with solvents and adhesives, then coated onto metal (aluminium or copper) foils which are then packaged together inside cells.

This is a very precise process – otherwise the quality of the battery is impacted. At WMG, around 20 battery cells per day can be produced. At a gigafactory, production would be closer to 20 cells per second.

How are batteries recycled?

To recycle batteries, fire is used to recover most of the metals. Water can then be used to get further metals that can’t be reached using heat alone. There are still difficulties however in recycling lithium or graphite, which make up a large percentage of the metals in the batteries themselves.

With 11 million tonnes of lithium-ion batteries expected to need recycling by 2030, the need to build domestic capacity to recycle them is greater than ever.

EV-elocity project recognised at prestigious engineering awards

The EV-elocity project, involving engineers and researchers from WMG at the University of Warwick, has won a Collaborate to Innovate Award, from The Engineer magazine, in the Energy & Environment category.

The Awards celebrate the very best engineering collaborations and innovations across the UK.

EV-elocity is a research and development project looking at increasing the uptake of electric vehicles by helping consumers to monetise their investment using vehicle-to-grid (V2G) innovation.

With vehicle-to-grid (V2G) technology, electric vehicle (EV) batteries could store electricity - when there is an abundant supply - to power homes and businesses and to discharge it back to the national grid when it is most needed.

businesses and to discharge it back to the national grid when it is most needed.

Researchers at WMG developed a new model that quantified the degradation in the vehicle’s battery because of different EV charging strategies. The model highlighted that it was possible to manage the battery to mitigate much of the degradation and it was possible to even extend battery life through proper control and battery conditioning.

This enables better use of renewable energy, lower carbon footprint, less pressure on the grid and financial savings, which can help electric vehicle owners pay back their investment.

The EV-elocity project has deployed V2G chargers in a range of locations across England as part of large-scale trials to gain technical, customer and commercial insights on the emerging technology. It is also investigating if, and how, additional use from V2G charging may affect EV battery life.

Professor of Systems Modelling, James Marco, explains: “One of the unique aspects of EV-elocity, was the integration of EV technology with future energy infrastructure, such as vehicle-to-grid, to demonstrate at scale how novel methods of EV charging can provide multiple benefits for both the consumer and the environment.”

The project, led by Cenex, a not-for-profit consultancy specialising in delivery of low carbon vehicles and energy infrastructure projects also involves the Universities of Nottingham and Warwick; Leeds and Nottingham City Councils; and CrowdCharge, a platform that integrates and optimises smart electric vehicle charges.

EV-elocity is funded by the Department for Business Energy and Industrial Strategy (BEIS) and the Office for Zero Emission Vehicles (OZEV), in partnership with Innovate UK, part of UK Research and Innovation.

Read more about the award-wining EV-elocity project here: EV-elocity Project | vehicle-to-grid (V2G) innovation with electric vehicles

Voi and Bumblebee Power partner on UK’s first wireless e-scooter charging trial launched at the University of Warwick

- Time-consuming and resource-intensive charging processes could be replaced by wireless charging for e-scooter rental fleets

- The ease of use for consumers and a reduction in operating costs through wider adoption of this technology would be a big advantage for the UK’s biggest rental scheme operator, Voi

- Trial in partnership with Bumblebee Power and WMG on the University of Warwick campus allows real-world testing in a ‘mini-city’ environment

- A successful trial will pave the way for seamless and convenient charging of e-scooters

Voi Technology, the UK’s largest e-scooter rental operator, has partnered with Bumblebee Power and WMG to trial the use of Bumblebee’s wireless e-scooter charging at the University of Warwick campus over a 6-month period potentially changing the future of the micromobility industry.

As with the charging of electric cars, the charging of e-scooters is a challenge for the operators of extensive rental schemes. The batteries powering their zero-emissions e-scooters are currently charged safely at their warehouse; however, they are replaced when vehicles are either receiving their regular in-house inspections or by the company’s in-field team who visit each e-scooter to perform fresh battery swaps.

These processes can lead to high operating costs for their business as the processes can be both time-consuming and often resource-intensive by requiring additional warehouse infrastructure for safe battery charging as well as transportation costs. Therefore, Voi began exploring new charging methodologies as a result that could provide the same excellent user experience whilst also delivering a similar vehicle efficient and effective battery performance. The potential solution: wireless charging.

additional warehouse infrastructure for safe battery charging as well as transportation costs. Therefore, Voi began exploring new charging methodologies as a result that could provide the same excellent user experience whilst also delivering a similar vehicle efficient and effective battery performance. The potential solution: wireless charging.

In partnership with Bumblebee Power, the wireless charging pads make it possible to charge e-scooters where they are parked, reducing not only operational costs but make their integration into the street and transport infrastructure more streamlined, making the modal shift to a convenient and flexible mode of transport easier for new and existing riders.

The University of Warwick campus ‘mini-city’ environment has been selected for this trial and provides an excellent, safe test bed for testing transport innovations. Available to estate staff only, a busy environment with a large population of students, staff, and industrial partners means the University of Warwick is an ideal ‘living lab’ environment to enable sustainable research and development of this technology.

The trial will provide data on the wireless system performance as well as user behaviour and interaction with the technology, which is crucial to any future large-scale deployment. If the trial proves successful it could be expanded to cover more of the Voi fleet across the UK.

David Yates, CTO of Bumblebee Power explains:

“The Bumblebee patented technology, which originated from Imperial College London, provides automatic connection via a very efficient wireless charging system, saving operational expenditure for the fleet operator by eliminating battery swaps. In addition, it makes possible the ability to extend the battery’s life, by controlling the charging regime whilst maximising vehicle availability.”

Sam Pooke, Senior Policy Manager at Voi UK and Ireland, said:

“We’re delighted to be partnering with Bumblebee Power to develop wireless charging for our e-scooters, an innovation that could change the whole micromobility industry.

“Applying this technology has the potential to not only reduce the operational impact of how we charge batteries for our vehicles but also in making an already convenient and flexible service even more accessible for new and existing riders. Over the coming months, we’ll look forward to working with our partners to maximise the innovative potential of this technology.”

David Evans, Lead Engineer at WMG, University of Warwick, said:

“Wireless charging technology for micromobility has the potential to reduce operational costs for fleet operators and provide a convenient charging solution for users. The University of Warwick campus is an ideal location to trial transport innovations such as these, providing a real world, mini city environment with world class teaching and research facilities.”

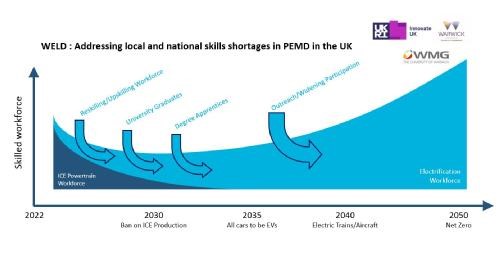

University of Warwick wins £1 million grant to help UK get ready for electric vehicles

- The funding will be used to launch a new programme called the Warwick Electrification Deployment (WELD)

- WELD will be contributed to by WMG's Power Electronics, Machines and Drives (PEMD) Group and the School of Engineering's Power Electronics group

- These two world class research groups will use Warwick’s unique facilities, as well as the university’s manufacturing and testing capability to help in the new education programme

- WELD is one of the winners of the ‘Driving the Electric Revolution: Building Talent for the Future 2’ competition, run by Innovate UK

- The new initiative will include industry workshops, outreach activity in school and increased teaching provision within PEMD

New content in power electronics, eMachines and drives will also be created at the University to use current expertise to both up-skill the existing workforce and support the pipeline of talent for future generations.

and support the pipeline of talent for future generations.

Finally, WELD will also focus on the design of IP-free eMachines, with parts manufacture, assembly and testing on campus to allow for hands-on learning.

As both transport and industrial equipment pivots from combustion technology to electrical power, skills for the design, manufacture and maintenance of electric drivetrains are increasingly in demand.

WELD will benefit from the two ‘Driving the Electric Revolution Industrialisation’ (DER-IC) facilities at the university: the Winding Centre of Excellence and the power electronics reliability and failure analysis space, both launching in Autumn 2022. The trained workforce will help UK businesses to develop and scale new PEMD technologies and manufacturing processes.

Dr Juliette Soulard, Associate Professor Electric Machines at WMG says: “Through our close collaboration with UK industry, we witness the huge difficulties faced when trying to recruit people with the right skills for PEMD research and development projects.

“The expertise exists in the UK, but the knowledge and skills transfer needs dedicated and urgent actions which normal higher education courses cannot deliver. WELD’s industry workshops with unique, hands-on learning about manufacturing and device testing aims to address this issue.”

Prof. Peter Gammon, Professor of Power Electronic Devices, Head of Research and Deputy Head of the School of Engineering says: “We are extremely proud to be leading the WELD project, which will help meet a national and international PEMD skills shortage.

“Our activities will also help increase the flow of engineering graduates into the industry via new PEMD and Automotive Electrification MScs, while an extensive outreach programme will help educate and inspire the next generation of engineers.”

ENDS

Note to Editors:

Useful Links:

Driving the Electric Revolution - Industrialisation Centres

WMG, University of Warwick

WMG is a world leading research and education group, transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes. As an international role model for successful partnerships between academia and the private and public sectors, WMG develops advancements nationally and globally, in applied science, technology and engineering, to deliver real impact to economic growth, society and the environment.

WMG is one of the founding partners of the High Value Manufacturing (HVM) Catapult and leads HVM Catapult activities on Transport Electrification and Connected and Autonomous Mobility. The Catapult network’s mission is to leverage research and educational expertise to de-risk innovation for UK manufacturing, to improve business resilience, productivity, competitiveness and sustainability.

School of Engineering, University of Warwick

The School of Engineering benefits from its multidisciplinary approach, with research covering a broad range of topics. Key themes of Energy, Biomedical Engineering, and Future Cities, Materials and Manufacturing, and Technology and Society provide a framework to the research efforts, which are underpinned by four discipline streams and fourteen research groups. The School employs some of the leading engineers in their field, who regularly publish papers in top ranking journals. There are currently over 150 students undertaking postgraduate research degrees and 55 65 research post-doctorate staff.

DER-IC

DER-IC (Driving the Electric Revolution Industrial Centres) is building a globally recognised, sustainable UK-wide network with the relevant skills and capabilities to deliver the PEMD (power electronics, machines, and drives) necessary for a net zero future in all relevant applications. The network of DER-IC is instrumental in the UK’s progress towards its 2050 net zero target and a world leading response to the realisation of the industrial technology (IDT) revolution.

DER-IC is funded by UK Research and Innovation and was set up in 2020 as part of the Driving the Electric Revolution challenge.

DER-IC provides open access facilities to over £300 million worth of state-of-the-art equipment, bringing together the UK’s technology and manufacturing expertise in electrification research and development.

§ DER-IC is creating cost-effective, UK-based technologies and solutions, with export market opportunities, to help address and support climate change

§ DER-IC is educating about the art of what’s possible for governments, industry, academia, and schools

§ DER-IC is an industry led project which has so far engaged with 400 industrial organisations, as well as having 30+ academic institutions and RTO’s in its network

Specialist electric motorcycle project hailed a great success

Today (Tuesday 12th July 2022), marks the official completion of the Triumph TE-1 electric development project, a unique four-way partnership between WMG at the University of Warwick, Triumph Motorcycles, Williams Advanced Engineering and Integral Powertrain Ltd e-Drive Division.

Today (Tuesday 12th July 2022), marks the official completion of the Triumph TE-1 electric development project, a unique four-way partnership between WMG at the University of Warwick, Triumph Motorcycles, Williams Advanced Engineering and Integral Powertrain Ltd e-Drive Division.

The TE-1 project was funded by the Office for Zero Emission Vehicles through Innovate UK, and was set up to create ground-breaking developments in specialist electric motorcycle engineering and innovative integrated technology design. The project provides an input into Triumph’s future electric motorcycle offering, driving innovation, new standards, capability, and new intellectual property, whilst enhancing the credibility and profile of British industry and design.

Driving lower environmental impact transportation, and delivering against the UK’s focus on reducing emissions, the project also aimed to develop strong, commercially viable and sustainable partnerships with UK industry manufacturers and supply chains, whilst building expertise and capability within the UK workforce.

Nick Bloor, CEO, Triumph Motorcycles, said: “We are incredibly proud to be able to share such positive outcomes from the completion of Project Triumph TE‑1, where the prototype demonstrator has exceeded many of our initial targets and expectations. Everyone on the team is thrilled with the results we have achieved with our partners, and how the outcomes of the project will feed into the electric future to come from Triumph.”

Released today, the final testing results show how the TE-1 prototype has delivered on all targets and objectives following an extensive live testing programme which involved numerous assessments of the bike’s performance on a rolling road as well as on track.

WMG’s role in the project was to provide electrification expertise, and the critical vision to drive innovation from R&D to commercial impact, through modelling and simulation based on future market needs.

Highlights from the testing results include a standing start acceleration of 0-60mph in 3.6 seconds, peak power of 130kW (177PS / 175bhp) as well as peak torque of 109Nm (80 lb-ft), a 20-minute charge time (0-80%) and a 161km / 100-mile range based on official testing and projections. At 220kg (485 lb), the TE-1 prototype is also lighter than the equivalent electric bikes available currently by up to 25%.

20-minute charge time (0-80%) and a 161km / 100-mile range based on official testing and projections. At 220kg (485 lb), the TE-1 prototype is also lighter than the equivalent electric bikes available currently by up to 25%.

Professor David Greenwood, CEO of the High Value Manufacturing Catapult at WMG, University of Warwick, explained: “To meet our ambitious emission reduction targets in the UK we will have to rethink the way we travel, not only transitioning from ICE to electric propulsion vehicles, but also encouraging a modal shift away from private cars. Electric two wheelers have a pivotal role to play in the transport revolution as a zero-tailpipe emission option.

“In our partnership with Triumph, WMG used our research experience in electrification to demonstrate manufacturers can deliver products with a lower emission burden as well as outstanding performance-offering customers an EV that is great fun to ride.”

Read more about WMG’s Transport Electrification research here: Energy (warwick.ac.uk)

Battery tech pioneer Britishvolt strengthens partnership with WMG, University of Warwick, to ramp up UK electric vehicle battery production

- The multi-million-pound [£] project with WMG, University of Warwick, is pioneering battery technology in the UK

- Research from WMG, University of Warwick, will help Britishvolt to ramp up the availability of batteries for electric vehicles, and other applications, in the UK and beyond

- The project is accelerating Britishvolt’s business plan to deliver a 38GWh battery Gigaplant, one of the largest industrial investments ever undertaken in the UK

- Britishvolt recently announced exciting plans for a scale-up production centre in the epicentre of the automotive industry located at Hams Hall, West Midlands, creating what it calls a “Battery Corridor” – linking the Northumberland site with the UK’s automotive heartland

- The Gigaplant will build enough cells each year for well over 300,000 electric vehicle battery packs, equivalent to [c]25% of current UK vehicle manufacture, securing Global Britain’s position on the sustainable battery production map

WMG has partnered with leading sustainable, low-carbon battery manufacturer, Britishvolt on a two-year multi-million-pound project which is pioneering battery technology in the UK.

battery technology in the UK.

More batteries for electric vehicles will become available in the UK thanks to research from WMG, at the University of Warwick and its partnership with battery tech pioneer Britishvolt.

The project is helping Britishvolt to deliver a 38GWh battery Gigaplant, one of the largest industrial investments ever undertaken in the UK. The facility, located in the North-East of England, will quickly increase the availability of batteries required at commercial scale for the electric vehicle market – playing a key role in helping the UK reach its carbon net zero target by 2050.

Following an initial 12-month project, Britishvolt and WMG are now embarking on a two-year programme of work. WMG’s research will assist with battery cell development and optimisation including small-scale manufacturing to produce battery electrodes and cells using Britishvolt target materials sets, formulations and cell designs. These will then be tested according to Britishvolt’s agreed protocols.

Professor Dave Greenwood, CEO of the High Value Manufacturing Catapult at WMG commented: “WMG is delighted to be supporting Britishvolt as they set up large scale battery manufacturing and research facilities in the UK. This industry will be critical for the future of the UK automotive and energy sectors. WMG has been investing over the last decade in the research and development capabilities needed to help Britishvolt and other battery companies to be internationally competitive now and in the future”

Dr Allan Paterson, Chief Technical Officer, Britishvolt, concluded: “Britishvolt are delighted to extend and expand our relationship and programme of work with WMG. The battery science, advanced materials and cell prototyping expertise and capability at WMG has directly, and positively, supported our battery technology development programme. This gives us not only an excellent basis to progress from, as we seek to scale and commercialise our technologies, but the relationship also enables Britishvolt to continue to develop our products further, as we continually strive to deliver best-in-class, market-leading, cell technologies to our customers.”

Dr Allan Paterson, Chief Technical Officer, Britishvolt, concluded: “Britishvolt are delighted to extend and expand our relationship and programme of work with WMG. The battery science, advanced materials and cell prototyping expertise and capability at WMG has directly, and positively, supported our battery technology development programme. This gives us not only an excellent basis to progress from, as we seek to scale and commercialise our technologies, but the relationship also enables Britishvolt to continue to develop our products further, as we continually strive to deliver best-in-class, market-leading, cell technologies to our customers.”

Britishvolt: Power with Purpose

The Northumberland Gigaplant – Britishvolt’s first large, full-cycle Gigaplant in the UK - will have a total capacity of over 38 Gigawatt Hours by the end of the decade and will produce enough cells far in excess of 300,000 electric vehicle battery packs per year, intended primarily for use in the automotive industry. The development is a major boost for Northumberland, and the UK, delivering around 3,000 direct skilled jobs and another 5,000-plus in the associated supply chains.

Britishvolt’s collaborations with academia, industry and private enterprise will also help transition the UK from fossil fuels to a low carbon, battery-based electric future.

The release of an official A-sample battery cell to customers, which is scheduled later in 2022, will help to further accelerate commitments.

Britishvolt recently announced that it will develop its UK battery cell scale-up facility in the West Midlands, home to the internationally renowned battery ecosystem With a budget exceeding £200m, the plan looks to create upwards of 150 highly skilled, well-paid jobs; unifying the Britishvolt Northumberland Gigaplant with a centrally located scale-up/technology hub

The Hams Hall site will spearhead new cell formats and electro chemistries to create higher performance, production ready, batteries of the future whilst helping lower cell costs for more affordable EVs, aiding mass adoption

Britishvolt is one of the fastest growing battery technology companies in Europe and globally. The company is also in discussions with the Canadian Government regarding its expansion plans in the country.

Watch Britishvolt’s Battery Research video: https://www.youtube.com/watch?v=3UlDcUjMhiE

WMG supports Norton Motorcycles as they announce plan to build electric motorcycles in the UK

WMG, at the University of Warwick, is supporting Norton Motorcycles in its intention to begin developing electric motorcycles in the UK after winning significant investment through a government scheme.

through a government scheme.

The iconic British motorcycle brand has been awarded funding by Advanced Propulsion Centre (APC) 19, an initiative which aims to assist businesses in the automotive sector in advancing their low-carbon offering while helping to accelerate the UK towards a net-zero automotive future, a future that Norton fully embraces.

As demand for electric motorcycles and micro-mobility solutions grow, the project, Zero Emission Norton, will expand Norton’s ever-growing electric vehicle engineering capabilities and develop world class electric motorcycles.

To deliver this ambitious project, Norton will work with specialist project partners who have the same vision for innovation in production of world-class electric motorcycles. The team encompasses Delta Cosworth, HiSpeed Limited, Formaplex Technologies, M&I Materials, INDRA and academic partner WMG at the University of Warwick.

Each partner on the project will have a specialist part to play in project Zero Emission Norton. Delta Cosworth will design the battery pack, while HiSpeed Limited bring motor design and manufacturing skills. Formaplex Technologies have expertise in precision composites manufacturing and M&I Materials will support on applications of dielectric cooling oils. INDRA specialise in vehicle to home charging technology and WMG major on battery technology, modelling and toolchain development.

Norton will work alongside these partners to develop world-class technology and products that will enhance the UK supply chain for all the critical components in electric vehicle (EV) technology including batteries, motors, chassis, cooling oils and vehicle to home chargers.

As a result, the 30-month project is expected to create a significant number of jobs in the UK in manufacturing and R&D as well as upskilling existing staff to be capable of electric motorcycle engineering. This in turn will help address the UK skills shortfall in that space while returning the UK to the position it last enjoyed in the 60’s, as the global technology leader for motorcycles.

Andrew McGordon, Reader, Energy Applications Group at WMG, University of Warwick, said: “WMG is excited to be a partner in this project exploiting our research in battery and systems modelling to develop a zero-prototype modelling and validation methodology, including predictive smart charging and Vehicle to Grid technology. We will bring extensive electrification experience to this project having worked across many sectors already.”

Robert Hentschel, CEO Norton Motorcycles commented: “This significant funding investment is a momentous milestone for the brand as it marks the beginning of our electrification journey and fulfilling our ten-year product plan.Norton is an exemplar of modern luxury and unafraid to challenge the status quo, innovating for the future of mobility while staying true to our British heritage. It also brings into focus our desire to support the UK in its mission for a net-zero automotive future.

“Working alongside our world class partners, we’re confident that project Zero Emission Norton will eliminate the current dispute between a conventional and electric motorcycle to create EV products that riders desire – motorcycles that blends Norton’s uncompromising design DNA with racing performance, touring range and lightweight handling.”

Ian Constance, Chief Executive of the APC said: "The projects receiving today’s investment highlight the breadth of technologies needed to help the UK accelerate to net zero emissions. They’re reimagining not just vehicles, but transport in general.

"Norton are an iconic British brand with a proud history. From making motorcycles to support the second world war effort to developing the world’s first production superbike, they are now looking to the future with an electric bike that will deliver both performance and range radiating from a UK manufacturing base and strengthening highly-skilled jobs and green growth."

Ends

For any enquiries, please contact Stephanie Staff at Performance Communications on

07798 897 692 or email norton@performancecomms.com

Website: www.nortonmotorcycles.com

Carbon, cost and battery conditioning benefits calculated for vehicle-to-grid chargepoints

Vehicle-to-grid chargepoints can improve battery life in electric vehicles and reduce carbon emissions and costs of charging, a government-funded project has found.

Research from the EV-elocity project shows that, by careful charging and discharging, EV battery degradation can reduce by one-eighth, and, in some situations, up to 450 kg of emitted carbon dioxide (CO2) or £400 could be saved per vehicle each year.

situations, up to 450 kg of emitted carbon dioxide (CO2) or £400 could be saved per vehicle each year.

Vehicle-to-grid (V2G) can balance the calendar and cycling aging (both of which affect the rate of battery degradation) to optimise the battery condition and improve its health by 8.6 – 12.3% over one-year’s operation, compared to conventional charging alone - equivalent to one extra year of use.

In cost-terms, V2G tariff optimisation can save around £100 per year per charge point on normal business electricity tariffs, with up to £400 saved on a smarter tariff.

If managed to maximise the environmental benefit, nearly half a tonne of annual CO2 emissions can be saved, and significant savings (over 180 kg) can be made even when reducing cost is the main goal.

Chris Rimmer, Infrastructure Strategy lead at Cenex and the project’s lead project manager, said: “Our conclusions show that it is not necessary to trade-off financial, environmental and asset lifetimes when charging Electric Vehicles. Cost, carbon, and conditioning benefits can all be gained when V2G is used intelligently with fleet vehicles.”

Professor Lucelia Rodrigues of the University of Nottingham added “a key challenge for an optimum application of V2G technology is to synchronize the needs and requirements of the users and the energy and transport systems. Our work correlated variables such as user needs, mobility patterns and renewable electricity generation to evolve different possible scenarios for the application of V2G chargers, with a view of maximizing local renewable energy consumption, lowering costs for the user, improving battery life and reducing carbon emissions from the whole system.”

“Our experimental research highlighted the potential to extend battery life by exploiting the unique capability of V2G chargers to both charge and discharge the vehicle battery”, commented Professor James Marco of WMG, University of Warwick. “By careful optimisation of this process and knowing how the battery performance may degrade over time, it is possible to condition the battery to extend its life in a number if situations when compared to conventional methods of vehicle charging.”

The EV-elocity Project was funded by Innovate UK, the Department for Business, Energy and Industrial Strategy, and the Office for Zero Emission Vehicles between September 2018 and January 2022; it was led by Cenex and comprised CrowdCharge, Leeds City Council, Nottingham City Council, University of Nottingham and University of Warwick in a second phase from January 2020.

The project deployed 15 chargepoints across nine sites - including West Midlands Police, Leeds City Council and the University of Nottingham Creative Energy Homes campus. Two of charger from eNovates and Nichicon were managed by a technology-agnostic operating system, demonstrating V2G across the different trial sites within the UK.

The final report presents the findings and lessons learned for future vehicle-to-grid deployment.

Ends

Notes to editors:

The EV-elocity project is part of the Vehicle-to-Grid (V2G) competition, funded by the Department for Business Energy and Industrial Strategy (BEIS) and the Office for Low Emission Vehicles (OLEV), in partnership with Innovate UK, part of UK Research and Innovation.

In January 2018, OLEV and BEIS announced that 21 projects (8 feasibility studies, 5 collaborative research and development projects, and 8 real-world v2g trial projects) were to receive funding of £30m to develop the business proposition and the core technology to support Vehicle 2 Grid deployment in the UK, including its demonstration with large scale trials.

The projects involve more than 50 industrial partners and research organisations from both the Energy and Automotive sector, marking the largest and most diverse activities on V2G in the world, and trialling more than 1,000 vehicles and V2G charger units across UK.

The V2G projects represent a significant step towards the transition to a low carbon transportation and a smart energy system. Allowing EVs to return energy to the Power Grid when parked and plugged for charging, will increase Grid resilience, allow for better exploitation of renewable sources and lower the cost of ownership for EV owners, leading to new business opportunities and clear advantages for EV users and energy consumers.

The University of Warwick supports RIFT Technology with a greener cost-effective electric motor

A cheaper and more environmentally friendly electric motor for electric vehicles is a step closer to market with the support of WMG at the University of Warwick.

WMG has provided valuable knowledge and expertise in developing a UK focused, cost-effective production and supply chain for RIFT (Reduced  Induction Field Torque) Technology’s development of RIFT-10; a design for electric motor drives that reduces copper and magnet weight reduction by around 50% and lower cost by 75%.

Induction Field Torque) Technology’s development of RIFT-10; a design for electric motor drives that reduces copper and magnet weight reduction by around 50% and lower cost by 75%.

The aim of the project was to help RIFT Technology; an R&D company bringing a product to market for the first time, advance RIFT-10 to a higher manufacturing readiness level (MRL 7), to get the motor closer to production, by rooting the supply chain in the UK, rather than abroad (given the disruption to supply caused by the pandemic) and supporting production of trial units.

WMG, is committed to delivering UK economic impact and achieving net-zero by supporting industry in accelerating new concepts to commercial reality. This supports the University of Warwick’s approach to sustainability - the Way to Sustainable – which focuses on the real-life implications of creating a sustainable future and the practical challenges of getting there - prioritising research expertise, sustainability in the curriculum, and developing solutions for the benefit of industry and society.

The team of experts at the University has facilitated the RIFT-10 project to deliver on creating revenue, jobs, CO2 reduction, and supply chain growth in the UK.

RIFT Technology has developed the RIFT 10-30 kW motor (RIFT-10) by taking an exciting innovation from their sister business (RIFT Actuators) and working with APC and the Niche Vehicle Network to get the motor to working prototype stage (installed on a G-Whiz). The novel electric motor configuration is proven to generate 10-30kW of power, torque from 0-400Nm and up to 10,000RPM as demonstrated with a prototype vehicle.

The RIFT 10 motor demonstrated unique advantages over conventional EV motors:

Environmental benefits of the project:

· The low sales cost and attractive features of RIFT-10 enable greater/earlier market adoption of EUV’s, resulting in a reduction of CO2 production over ICE vehicles.

· A RIFT-10 weight saving and efficiency over competing EV motor designs increase vehicle range, resulting in less energy usage over alternatives.

· With RIFT-10, equivalent power output is achieved using fewer raw materials (i.e., 85% reduced copper weight and ~85% reduced magnet volume), resulting in less earth material usage as well as fewer material costs.

· Less materials usage results in an estimated 75% reduction in CO2 produced during manufacture. Planned production efficiencies also lead to further CO2 reductions. An estimated 612,000 Tonnes of CO2 would be saved by year 5.

· Development of an EV motors supply chain in the UK for a UK and EU market reduces international shipping of components thus reduces related CO2 production.

Social benefits of the project:

· RIFT-10 creates/safe-guards 50+ much needed and good-quality manufacturing, sales, administration and R&D jobs in the Malvern area with an estimated X14 more UK jobs across the supply chain (over 5-years).

· Growth of RIFT-10 addresses the government’s priority area of ‘Smart Cities’ by allowing smart monitoring of vehicle fleets efficiency performance, usage and other data points. The use of the Internet of Things and resulting analysis can only be as strong as the data input. Traditional alternatives offer no smart functionality.

James Black, WMG Innovation Manager at the University of Warwick said, “The Covid-19 pandemic has been particularly difficult for SMEs and R&D-focused organisations that have previously relied on face-to-face networking events to find new partners, investors, and customers.

“WMG’s network means we’re in a great position to connect UK companies together to help them accelerate their product to the market, and we’re delighted that RIFT Technology has benefited from our extensive background for practical supply chain solutions that have delivered economic and societal value to the project.”

James O’Donnell, Technical Manager from RIFT Technology said, “As a research and development company bringing a product to market for the first time, RIFT Technology needed to bridge the gap between prototype and small-scale production. We had to answer difficult questions such as what to make and what to buy, high level questions such as how to develop a supply chain strategy and practical questions such as how best to select suppliers.

“With a unique blend of academic expertise and industrial experience from the University of Warwick, WMG’s Supply Chain and Operations Group were able to support us in our journey.”

The project took place during the pandemic, meaning several online workshops were carried out targeting topics such as strategic management, supplier selection and decision-making, and end-of-life strategies.

For further stories, click here.

ENDS

4 April 2022