WMG News

Consortium established to tackle decarbonisation of cross-Channel ferry fleet

WMG at the University of Warwick is playing a key part in a new research project supporting the UKs pledge to achieve net-zero by 2050.

WMG at the University of Warwick is playing a key part in a new research project supporting the UKs pledge to achieve net-zero by 2050.

The seven-month project, entitled the Dover Clean Ferry Power, is a collaboration between the Port of Dover, P&O Ferries, WMG and Schneider Electric, led by Kent Business School at the University of Kent.

The project, which is part of a £20 million programme funded by the Department for Transport, will investigating the decarbonisation of the cross-Channel ferry fleet and in turn support the delivery of the Port of Dover Air Quality Action Plan.

Currently, Port of Dover vessels spend energy through in-harbour activity, open sailing and on-vessel services (such as heating, lighting and hospitality). Some vessels are hybrid; self-charging on-board batteries whilst in open sailing and then using the battery charge whilst in-harbour.

This project will model ferry operations at Dover to establish energy requirements, CO2 effects, air quality and running costs, using this to evaluate technical solutions for both ferries and the port, to accelerate the move to net zero. Insights gained may then have the potential to extend to cruise and cargo operators, as well as adaptation of experienced vessels.

Researchers and engineers at WMG High Value Manufacturing Catapult Centre will be undertaking all of the battery modelling and analytics, plus energy and CO2 modelling for the port of Dover and for vessels using the port– which will impact the locals as well as the environment more widely.

Phil Whiffin, WMG Head of Energy Applications Group, explains: “This project builds on our existing zero emission transport expertise and allows us to apply the MIMO (Multi-Input Multi-Output) modelling technique developed by Dr Andrew McGordon to investigate the complex operations of a port. It will support investment and operation decisions for Dover and the ferry operators and ensure the optimum strategy is in place to move towards net-zero. Dover is an essential trade gateway for the UK so this is a project of great strategic importance and we are pleased to be part of this great consortium.”

Simon Barnes, Project Manager and Funding & Partnership Development Manager within the University of Kent’s Research & Innovation Operations, said: ‘For the University of Kent, this new project builds on a previous successful work with the Port of Dover and is an excellent example of a collaborative project with the University, industry partners and consumers.

‘It is our unified aim to investigate potential avenues that can lead to reductions in carbon emissions as part of the national priority of net-zero. The University of Kent is dedicated to the endeavour through a series of initiatives, with the Dover Clean Ferry Power project as a prime example of the role we play regionally and in applying intensive research to vital national goals.’

ENDS

Notes to Editors

(1)

Clean Maritime Demonstration Competition

The Dover Clean Ferry Power Project is part of the Clean Maritime Demonstration Competition, funded by the Department for Transport and delivered in partnership with Innovate UK.

Announced in March 2020, and part of the Prime Minister’s Ten Point Plan to position the UK at the forefront of green shipbuilding and maritime technology, the Clean Maritime Demonstration Competition is a £20m investment from government alongside a further c.£10mfrom industry to reduce emissions from the maritime sector. The programme is supporting 55 projects across the UK, including projects in Scotland, Northern Ireland and from the South West to the North East of England. As set out in the Clean Maritime Plan (2019), Government funding has been used to support early-stage research relating to clean maritime. The programme will be used to support the research, design and development of zero emission technology and infrastructure solutions for maritime and to accelerate decarbonisation in the sector.

Lead-acid battery lifespan to be increased for use in energy storage systems

· Lead-acid batteries are an established alternative to Li-ion batteries as they are simpler safer to use and are recyclable

· How to increase the lifespan and health of batteries will be researched by WMG, University of Warwick, in collaboration with Loughborough University. This research will make lead acid batteries stronger contender for both commercial and domestic energy storage systems

· Researchers will be using AI to optimise the batteries for energy storage solutions rather than focusing on the battery chemistry

Energy storage systems (ESS) are used in decentralised and complex electricity networks; lead-acid batteries could be a clean and green option for ESS. Researchers from WMG University of Warwick and Loughborough University will investigate how to optimise the management of lead-acid batteries in ESS use.

Energy storage systems (ESS) are used in decentralised and complex electricity networks; lead-acid batteries could be a clean and green option for ESS. Researchers from WMG University of Warwick and Loughborough University will investigate how to optimise the management of lead-acid batteries in ESS use.

Europe’s energy storage transition over the last few years has witnessed tremendous growth, increasing from 0.55 GWh 2016 to 5.26 GWh by the end of 2020, with front-of-the-meter deployments such as those by utilities leading the way, representing more than 50% of installed capacity.

These energy storage systems require high-performing, reliable and affordable batteries to ensure the smooth generation and storage of energy for regional and national electrical grids.

The health and lifespan of lead-acid batteries will be optimised in the project HALO-SMART-ESS-LAB (Health and Lifespan Optimization with Smart Manager Algorithms and Recuperative Testing of Energy Storage Systems of Lead-Acid Batteries).

The aim of the project, which is funded by the Consortium for Battery Innovation (CBI), is to achieve significant improvements in cycle life and operational health of lead-acid batteries in energy storage systems (ESS), thereby opening new doors in integrating renewable energy sources into low carbon energy systems.

Extending the lifespan of the batteries will reduce the cost of the overall system, making lead batteries more attractive for domestic, commercial and industrial applications. As well as being cost effective, lead batteries are much safer than Li-ion batteries in terms of health and safety and fire hazards risks, and are widely and fully recyclable.

Researchers from WMG at the University of Warwick will be working with Loughborough University, to focus on application and system operation levels, rather than on internal battery chemistry or technology levels. Existing state-of-the-art battery types such as VRLA AGM batteries will be tested under different cycling profiles to explore in-depth:

· The use of appropriately spaced recuperative charging (overcharging)

· Deeper understanding of the ripple current effect on the ESS

· The use of additional on-line battery voltage monitoring or full BMS

· Applying deep learning algorithms and AI to achieve optimised control strategies decreasing wear-out and failure of battery modules.

Principal Investigator, Professor Richard McMahon from WMG, University of Warwick comments: “Energy Storage Systems are a key solution to more decentralised and complex electricity networks, as they can support their stability and maximise the utilisation of renewable generation capacity. We are therefore looking at how we can maximise the cycle life of lead-acid batteries to get the most out of them and make them cheaper and greener for all kinds of renewable energy uses.”

Professor Dani Strickland from Loughborough University adds:

“The availability of low-cost powerful microprocessors is fuelling an explosion in our capability to monitor, understand and impact battery degradation in real world situations at low cost. This project is exciting because it will use expertise in the partner organisations to transition lead acid batteries to the world of big data and smart energy storage.”

CBI’s Technical Manager, Dr Matt Raiford, said: “This kind of collaborative research with universities is exactly what the lead battery industry needs. Working with leading institutions to deliver new insights and modelling techniques for lead battery energy storage is critical for the wider industry to continue their foray into the utility grid storage market.”

ENDS

7 JUNE 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/may_2021/mcmahon_1.jpg

Caption: Isolated multichannel battery and cell voltage measuring circuit for use in series strings

Credit: WMG, University of Warwick

Video available to view at: https://biteable.com/watch/2966892/32fa5ade7e8821ec12ec53c21b9b57e4

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Charging ahead with battery research

WMG has been named as a partner in five key battery research projects funded by the Faraday Institution.

WMG has been named as a partner in five key battery research projects funded by the Faraday Institution.

The Faraday Institution has committed £22.6m to battery research projects involving a consortium of universities around the UK.

Research will progress over the next two years to 31 March 2023. The projects, involving WMG, are:

· SOLBAT. The solid-state battery (SSB) is one of the most important challenges in battery R&D. As well as increasing energy density, lifetime and transforming safety, SSBs will enable step changes in the safety, driving range and longevity of electric vehicles. Read more here: SOLBAT – Solid state metal anode batteries – The Faraday Institution

· SafeBatt – the science of battery safety. Safety control and countermeasures are built into the design of today's Li-ion batteries (LiB) systems, but this adds complexity, cost and weight. As the use of LiBs expands further into automotive, stationary storage, aerospace and other sectors, there is a need to decrease the risk associated with battery usage further and to enable the simplification of safety systems. This can only be achieved through enhanced understanding of the “science of battery safety.” Read more here: SafeBatt – Science of Battery Safety – The Faraday Institution

· Battery Degradation. Although mass manufacture has made lithium-ion batteries cheaper, cost and durability remain obstacles to the widespread adoption of battery electrical vehicles. The lifetime of the batteries falls well below the consumer expectation for long-term applications such as transport. The automotive industry wants to better understand the causes and mechanisms of degradation to enable improved control and prediction of the state of health of battery systems. Read more here: Battery Degradation – The Faraday Institution

· Multi-scale modelling. The performance and lifetime of a battery depends on how the cells are combined into a pack large enough to power an electric vehicle (EV), an aeroplane or even an electricity grid. The mechanism controlling the local environment of each cell within that pack also influences lifetime and performance. The first challenges to be tackled include fast charging of batteries, low temperature operation and thermal management of cells within battery packs. Read more here: Multi-scale Modelling – The Faraday Institution

· Nextrode Electrode Manufacturing. Nextrode focuses principally on manufacturing research into how to engineer a new generation of battery electrode structures. Novel developments in electrode structuring will be drawn from basic science understanding of the current slurry casting manufacture of Li-ion electrodes along with predictive modelling to suggest how control of electrode microstructure can deliver improved energy storage characteristics. Nextrode will support UK manufacturers and supply chain companies, draw on cutting edge scientific and technological knowledge to produce increased cell performance, add value in electrode processing, and improve safety and sustainability. Read more here: Nextrode – electrode manufacturing – The Faraday Institution

Meet the team and read more about WMG’s Energy research here.

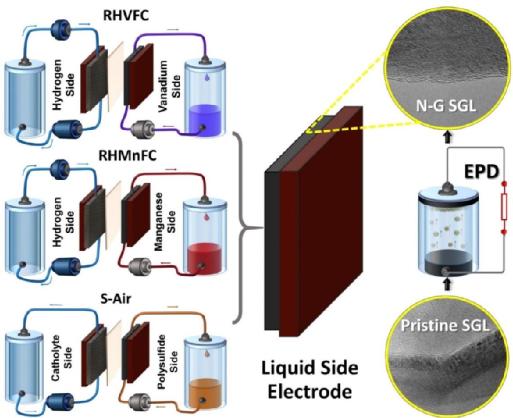

Highly efficient grid-scale electricity storage at fifth of cost – researchers modify hybrid flow battery electrodes with nanomaterials

Researchers in WMG at the University of Warwick, in collaboration with Imperial College London, have found a way to enhance hybrid flow batteries and their commercial use. The new approach can store electricity in these batteries for very long durations for about a fifth the price of current technologies, with minimal location restraints and zero emissions.

The researchers enhanced three hybrid flow cells using nitrogen doped graphene (exposed to nitrogen plasma) in a binder-free electrophoresis technique  (EPD)

(EPD)

Wind and solar power are increasingly popular sources for renewable energy. Unfortunately, intermittency issues keep them from connecting widely to the National grid. One potential solution to this problem involves in the deployment of long-duration battery technology, such as the redox flow battery. Despite its great promise the current costs of this system are a key determining factor to real-world adoption. An affordable grid battery should cost £75/kWh, according to the US Department of Energy. Lithium-ion batteries, which lead the charge for grid storage, cost about £130/kWh.

Now WMG researchers have found a way of enhancing hybrid flow batteries or regenerative fuel cell (RFC) technology that could store electricity for very long durations for about one-fifth the cost of current storage technologies, with flexibility in siting and with minimal environmental impact. The technology combines carbon-based electrodes with economically sourced electrolytes, (manganese or sulphur, which are abundant chemicals in the planet) by means of a simple and yet highly effective electrophoretic deposition of nano-carbon additives (nitrogen-doped graphene) that enhance the electrode durability and performance significantly in highly acidic or alkaline environments.

The researchers have published their findings in a paper entitled, ‘Hybrid Redox Flow Cells with Enhanced Electrochemical Performance via Binderless and Electrophoretically Deposited Nitrogen-Doped Graphene on Carbon Paper Electrodes’ in the December 2020 edition of the journal ACS Applied Materials & Interfaces.

Dr Barun Chakrabarti, a Research Fellow in WMG at the University of Warwick and one of the lead authors on the paper said:

“This EPD technique is not only simple but also improves the efficiencies of three different economical hybrid flow batteries thereby increasing their potential for widespread commercial adoption for grid-scale energy storage.”

The hybrid flow battery’s total chemical cost is about 1/30th the cost of competing batteries, such as lithium-ion systems. Scaled-up technologies may be used to store electricity from wind or solar power, for multiple days to entire seasons, for about £15 to £20 per kilowatt hour. These batteries are also extremely useful for grid-scale load levelling applications as their design is very flexible due to their unique feature of sizing their power independently of their energy.

The energy density of a hybrid flow battery, especially the polysulphide/air system (S-Air), is 500 times higher than pumped hydroelectric storage. It is also so much more compact and can be placed near any renewable generation.

ENDS

22 JANUARY 2021

Notes for Editors

High-res image available at:

https://warwick.ac.uk/services/communications/medialibrary/images/january_2021/barun_release_image.jpg

Caption: A Binder-Free Horizontal Electrophoretic Deposition (EPD) Process Is Used to Activate Commercial Carbon Paper Electrodes Using Nitrogen-Doped Graphene

Credit: WMG, University of Warwick

Full list of researchers: Co-investigators with Dr Chakrabarti at the WMG Energy Innovation Centre at the University of Warwick are: Evangelos Kalamaras (Project Engineer, Battery Testing) and Professor Jon Low (Associate Professor, Electrochemical Engineering). Co-investigators from Imperial include Anthony Kucernak and Nigel Brandon.

The full paper with all author details can be found here: Hybrid Redox Flow Cells with Enhanced Electrochemical Performance via Binderless and Electrophoretically Deposited Nitrogen-Doped Graphene on Carbon Paper Electrodes

Background history to this area of research

Development of the EPD technology began in 2013, when Professor Low joined WMG as an Assistant Professor and researched industrial Lithium-ion battery manufacturing processes. EPD involves the migration of electrically charged particles through a fluid that is under the influence of an electric field generated by applying the right potential.

Although EPD is an industrially adopted process such as for depositing industrial coatings onto conductive substrates, its mass-scale adoption for energy storage applications has only recently seen some success. Supported by EPSRC’s First Grant (EP/P026818/1, https://gtr.ukri.org/projects?ref=EP%2FP026818%2F1) and Industrial Strategy Challenge Fund on battery and supercapacitor manufacturing (EP/R023034/1, https://gtr.ukri.org/projects?ref=EP%2FR023034%2F1), Low’s research team have developed EPD for preparing lithium-ion battery electrodes that meet industrial standards for thickness and mass loadings and published their finding in ‘Batteries and Supercaps’ (https://chemistry-europe.onlinelibrary.wiley.com/doi/full/10.1002/batt.201900017). They have also produced carbon electrodes with nanomaterials for improving the practical performance of vanadium-based flow batteries using deep eutectic solvent electrolytes, and published their finding in ‘Batteries’ (https://www.mdpi.com/2313-0105/6/3/38).

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG part of new eLV car battery project

WMG, University of Warwick is part of a new project to create a new circular end-of-life supply chain for the electric vehicle industry. The project, led by EMR has won grant support from the UK Government’s Advanced Propulsion Centre.

WMG, University of Warwick is part of a new project to create a new circular end-of-life supply chain for the electric vehicle industry. The project, led by EMR has won grant support from the UK Government’s Advanced Propulsion Centre.

RECOVAS is a partnership between WMG, EMR, three major vehicle manufacturers; Bentley Motors, BMW and Jaguar Land Rover, the Health and Safety Executive, the UK Battery Industrialisation Centre, Autocraft Solutions Group, Connected Energy, which repurpose electric car batteries and uRecycle, which will develop the UK’s first commercial scale recycling facility for automotive battery packs.

Under current EU law and also post Brexit, manufacturers retain responsibility for the safe disposal of electric car batteries. There are already 164,100 pure electric vehicles on Britain’s roads, with that number rising to 373,600[1] when plug-in hybrids are included. This project aims to provide a standardised and reliable route for recycling and repurposing lithium ion car batteries at a scale that can cope with the expected sales of electric vehicles in the UK.

The project will start in January 2021 and will run for 3 years, by which time the partners expect the circular supply chain to be operating commercially.

Remanufacturing is the process of repairing and re-engineering existing batteries so they could potentially be used in new cars. Reuse involves giving batteries a second life in stationary storage to help balance the use of the electricity grid during peak use and optimise the use of renewable energy and other applications. The new supply chain will help all partners to triage batteries when they arrive at approved end-of-life vehicle treatment facilities across the UK for either remanufacturing, reuse or – where this is not possible – recycling.

Professor David Greenwood, CEO of the High Value Manufacturing Catapult, WMG, University of Warwick, said:

“Delivery of end-of-life provision for electric vehicle batteries is a strategic necessity for the UK, and this project will establish its first full scale facility. Without proper provision, end of life batteries could become a major safety and environmental concern.

“This project will implement state-of-the art recycling methods to meet and exceed the requirements of the current regulations. In addition, we will conduct research into new processes which could make the recovery of a much higher proportion of the battery material economically feasible. In doing so we will reduce the need for mining and refining of critical materials and we will reduce the carbon footprint of future electric vehicles. WMG is delighted to be at the core of this project, and we look forward to its delivery.”

Roger Morton, Managing Director for Technology and Innovation at EMR, said: “Our aim is to create a circular supply chain for batteries and, in the process, reduce the cost for end-of-life disposal for the vehicle manufacturer or last owner of the car to zero. By working in partnership with the RECOVAS consortium, electric vehicle manufacturers will develop simple design changes that greatly improve the potential to remanufacture, reuse or recycle their batteries at end of life. This will help to transform the economics of the electric vehicle market.”

Ian Constance, Chief Executive at the APC said: “Recycling of electric vehicle batteries is a principal part of the electric supply chain, so it’s vital that we get it right. The investment in innovative projects like RECOVAS, by EMR Metal Recycling, awarded as part of our APC 16 programme, demonstrates the importance of creativity and engineering excellence in the UK’s bid for a sustainable and commercial net-zero future.”

Developing and managing the infrastructure to process end-of-life electric vehicles and their batteries will generate new economic activity for the UK and create over 550 green jobs in the UK within the consortium members and their supply chain.

As part of the project, leading automotive manufacturers have agreed to share more information about the design and construction of their batteries, allowing the consortium to more effectively and efficiently repurpose or recycle them.

Morton added: “We have a very strong electric vehicle industry in the UK and it is changing fast. RECOVAS is an essential part of the sustainable roll out of electric vehicles.”

The UK Government is supporting RECOVAS as part of a £49m investment in technologies that will help the automotive industry to “go green”.

Minister for Business and Industry, Nadhim Zahawi MP, said the investment showed that the UK “is leading the global battle against climate change”.

He added: “Backed by government funding, these trailblazing projects will help the UK to build back better by creating all-important green jobs, ensuring the sector can make further strides towards an electrified automotive future.”

ENDS

27 NOVEMBER 2020

NOTES TO EDITORS

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

The next generation of WMG engineers

Congratulations to the 2018 cohort of Graduate Trainee Engineers who have all now successfully completed the Scheme, and secured new positions as Project Engineers at WMG.

Over the last two years the eight graduates; Harry Chan, Edward Griffin, Katerina Gonos, Jet Feng, Ben Ayre, Adam Szypula, Vidya Narayanan and Puja Unadkat; have been developing their engineering skills by working with academics and industry partners on either autonomous vehicles or energy innovation research.

Over the last two years the eight graduates; Harry Chan, Edward Griffin, Katerina Gonos, Jet Feng, Ben Ayre, Adam Szypula, Vidya Narayanan and Puja Unadkat; have been developing their engineering skills by working with academics and industry partners on either autonomous vehicles or energy innovation research.

Several of the graduates have also had their work published in leading academic journals and shared their expertise at key industry events.

In addition all eight have also supported WMG’s Outreach programme by taking part in workshops, demonstrations and talks with local school children including at the University’s Family Day events.

WMG’s Graduate Scheme Manager, Louise Oddy explains: “The recent success of our graduates is a true testament to their consistent hard work, determination and professionalism. They have made a lasting impact across several areas of WMG and will continue to do this within their roles as Project Engineers. Growing our own talent is integral to the future success of WMG and I could not be prouder of all of the Graduate Engineers. Thank you to those across the department that continue to support the scheme and make our programme so unique.”

Project Engineer, Ed Griffin adds: “WMG is an exceptional organisation where the graduate scheme promotes excellent tailored development in each graduate’s individual technical field. Our exposure to a range of cutting-edge automotive research, combined with various project management opportunities, is now invaluable in our Project Engineer roles.”

Project Engineer, Ed Griffin adds: “WMG is an exceptional organisation where the graduate scheme promotes excellent tailored development in each graduate’s individual technical field. Our exposure to a range of cutting-edge automotive research, combined with various project management opportunities, is now invaluable in our Project Engineer roles.”

Find out more about the WMG Graduate Scheme here.

Aerospace electrification: Accelerating the opportunity

The Aerospace Electrification event with WMG and ATI successfully brought together thought leaders and experts from across the aerospace supply chain and other sectors.

The Aerospace Electrification event with WMG and ATI successfully brought together thought leaders and experts from across the aerospace supply chain and other sectors.

Such events are vital to understand the opportunities and challenges faced by the sector, and a collaborative approach combining industry and academia will help the UK to continue its place at the forefront of transport electrification.

A series of presentations, workshops and Q&A led to a lively critical analysis of the topics at hand for aerospace electrification. These included safety, energy storage, electric drives, power electronics, thermal management, whole-vehicle optimisation and many more.

Alison Meir, Head of Business Development, WMG HVM Catapult, chaired the event, and introduced our first speaker, Mark Scully, Head of Advanced Systems and Propulsion at the ATI, who set the scene. Aerospace electrification has been a topic for some time now and technology is developing apace, with propulsion systems, subsystems and ancillaries all being electrified. Mark highlighted huge opportunities for the sector, with funding from UK Government supporting collaborative R&D in electrification. The ATI welcomes enquiries from industrial, academic and other stakeholders looking for R&D support.

Battery technologies and associated key metrics were presented by David Rawlins, Chief Technology Officer (CTO) at WMG. The safety-conscious nature of the aerospace industry has typically led to a modest pace of development in such technologies compared with, say, automotive. David identified that aerospace engineers are trained to design for perfection, but with future architectures and technologies still fledgling, no one knows what the perfect or ‘right’ solution yet is. So, there is opportunity for faster paced R&D. There is a growing evidence base on the limitations of battery technology and the trade-offs of power density against energy density, primarily driven by the automotive sector. As such, it is vital that the sector remains committed to influencing and leading battery technology for aerospace. An example is the ATI ACCEL programme, involving Electroflight and Rolls Royce, in partnership with Yasa, WMG and more. The continual need to engage with and influence the regulatory bodies for safety and certification was a poignant discussion point.

Future hybrid and all-electric aircraft will use radically different architectures to the aircraft of today, enhancing the need for a holistic systems engineering approach to design and integration. Sarabpal Bhatia, E-Fan X R&T Coordination Manager at Airbus, provided insight into the considerations currently underway at Airbus and the wider industry. Sarabpal reinforced that the aerospace and aviation industries have learnt many lessons since the dawn of flight and the jet age and that, as a collaborative sector, we must continue to learn lessons together. The integration challenges discussed included thermal management, high-voltage systems and arcing, human-machine interface, electromagnetic interference and protection. All of which are providing engineers with intricate problems to solve for future architectures.

On the topic of electric machines and more-electric aircraft (MEA), Marc Holme, Senior Director, at Collins Aerospace was able to share insight to delegates. The Boeing 787 currently has significant electrical energy generation capability (>1MVA) with electrification of pneumatic and environmental control systems. Marc identified that there are further electrification opportunities on the current fleet of conventional aircraft with technologies such as:

- Higher performance magnetics.

- Higher voltage systems.

- Improved semiconductor device efficiency.

The primary drivers for these are currently size, weight, power and cost. For future vehicles, electrical machines, power densities, power electronics and integrated drives, increased operating temperatures and systems safety were all topics of discussion. Composite enclosures for electrical machines were introduced, with the lower weight being traded for potentially lower EMI immunity.

These insightful presentations were followed by a series of hands-on workshops chaired by WMG and ATI to identify and address the key challenges and identify ways to overcome them. Following these sessions, delegates fed back and were able to ask questions of our expert panel.

During the Q&A, creation and availability of technology roadmaps was of interest. Roadmaps across electrification technologies have been produced by the ATI with industry and are available on the ATI's website.

Batteries and stored energy created much discussion. The thermal implications of energy storage failure cases were discussed and identified as a key challenge both at pack level and cell level. The design of experiments for a system with hundreds or thousands of battery cells is a complex topic ripe for innovation. Battery degradation over operational lifetime was discussed with the design considerations and in-service detection being key challenges. David Rawlins provided insight into how Lithium-ion cells are still leading for cost and volume primarily driven from the automotive sector.

The operational considerations of all-electric aircraft were also discussed. The flight-level optimisation of an aircraft that does not burn fuel (and lose mass) was challenged with the opportunities still all to play for.

Overall, the event was attended by a wide range of industry and academic contributors, all of whom believed that aerospace electrification holds huge opportunity for the UK. The Government’s net zero agenda, initiatives and R&D funding mean that aerospace electrification will require collaborative innovation for years to come.

The recording of the event and detailed challenge sessions overviews are available here.

£22m battery and thermal energy facilities launch at the University of Warwick, for a cleaner greener future

Two research centres for sustainable electrical and thermal energy technologies totalling £22m are launching at WMG, University of Warwick on the 10th June 2019. The funding from government via the Energy Research Accelerator (ERA) sees UK Government, industry and higher education work together to shape the future of the UK’s energy landscape.

Two research centres for sustainable electrical and thermal energy technologies totalling £22m are launching at WMG, University of Warwick on the 10th June 2019. The funding from government via the Energy Research Accelerator (ERA) sees UK Government, industry and higher education work together to shape the future of the UK’s energy landscape.

The Energy Research Accelerator (ERA) is a £60m project funded by Innovate UK. ERA is working with UK government, industry and the higher education sector to undertake innovative research, develop the next generation of energy leaders, and demonstrate low carbon technologies that help shape the future of the UK’s energy landscape.

ERA consists of eight internationally renowned Midlands universities – which includes the University of Warwick, who are part of the Midlands Innovation partnership, together with the British Geological Survey.

Together they will explore the challenges of energy and electrification, with some of the thought leaders and innovators who are making changes in these areas. There will also be an opportunity to tour the new research facilities.

WMG’s Energy Innovation Centre is a world-class facility for battery research from materials and electrochemistry to application integration and recycling/reuse. The £20m ERA investment has enabled new equipment and facilities, which include laboratories, a dry room for cell assembly, characterisation at cell, module and pack levels, innovative charging infrastructure and second-life evaluation facilities. It will drive the development, and scale-up of new battery chemistries from concept through to proven traction batteries.

The School of Engineering’s Sustainable Thermal Energy Technologies group develops low carbon heating and cooling technologies. The £2m ERA funding has enabled the extension of the Thermal Properties Lab into five newly-refurbished test cells to accommodate additional equipment for analysing thermal properties of materials and the Thermal Technologies Lab has benefitted from new test equipment and control/data logging facilities.

The School of Engineering’s Sustainable Thermal Energy Technologies group develops low carbon heating and cooling technologies. The £2m ERA funding has enabled the extension of the Thermal Properties Lab into five newly-refurbished test cells to accommodate additional equipment for analysing thermal properties of materials and the Thermal Technologies Lab has benefitted from new test equipment and control/data logging facilities.

Professor Pam Thomas, Pro-Vice-Chancellor for Research at the University of Warwick, comments:

“The University of Warwick continues to produce innovative research in battery development and thermal energy, the funding means we can help research ways to tackle global challenges in areas such as energy and sustainability to help climate change for the UK’s and the world’s future.”

Professor Martin Freer, Director of the Energy Research Accelerator, commented:

“Over the coming years we are going to see a step change in the motor industry from the combustion engine to battery powered vehicles. With this investment from ERA and Innovate UK, the Midlands will continue to take the lead in the research, development and commercialisation of new battery technologies.

“Our investment in the thermal labs here at Warwick is also significant, as the new facilities will enable researchers to work together with other ERA universities to develop innovative and efficient low carbon heating and cooling technologies.”

Andy Street, Mayor of the West Midlands comments:

“This world-leading research facility will further cement the West Midlands’ position at the cutting edge of innovation in technology and sustainability.

“The region is already at the forefront of the development of electric vehicle efficiency, and now the ERA’s funding will enable us to make better use of electrification to reduce emissions and improve transport, making a real difference to the lives of people living and working in the West Midlands.”

ENDS

10 JUNE 2019

NOTES TO EDITORS

This area of research is aligned with the Sustainability theme in our Research Strategy, which reflects our wider research into tackling global challenges in areas such as energy and sustainability climate change.

The Energy Research Accelerator (ERA)

ERA is a key programme within Midlands Innovation – a consortium of research intensive universities (universities of Aston, Birmingham, Cranfield, Keele, Leicester, Loughborough, Nottingham and Warwick), and the British Geological Survey (BGS), which has the overall aim of harnessing the Midlands’ combined research excellence and industry expertise to play a critical role in tackling some of the biggest challenges facing the UK.

Via Innovate UK, the government has committed an initial capital investment of £60m, and ERA has secured private sector co-investment of £120m. ERA’s initial priorities of Geo-Energy Systems, Integrated Energy Systems and Thermal Energy will help deliver the new technologies and behaviours that will open the avenues for its future development and demonstrate the transformative effect ERA can have across the energy spectrum.

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

First look at Coventry’s Innovative Light Rail Vehicle

Engineers and researchers at WMG, University of Warwick, are working alongside Transport Design International (TDI), based in Stratford, to develop a battery-powered, lightweight, rail-based vehicle to operate in Coventry.

The WMG team, including engineers Darren Hughes and Andrew McGordon, are using their automotive engineering and battery expertise to assist TDI with the design of the vehicle for Coventry City Council, and now have a 3D simulation of the vehicle.

The WMG team, including engineers Darren Hughes and Andrew McGordon, are using their automotive engineering and battery expertise to assist TDI with the design of the vehicle for Coventry City Council, and now have a 3D simulation of the vehicle.

The vehicle will be battery-powered with the long term objective that it will become an autonomous vehicle, allowing more vehicles to operate intelligently and efficiently to meet passenger demand.

It will hold 50 passengers, and the longer term aim is that it will work like the London Underground system, where there is no timetable and people can hop on and off.

The vehicle will be a lightweight design using multiple materials including aluminium, steel and composites.

Due to being battery-powered there will be no overhead power supply which is both costly and has a negative impact to the city-scape. This feature provides future flexibility for operating on other non-electrified routes.

The first-of-a-kind design is available to view in 3D via WMG’s visualisation suite and the first test vehicle will be manufactured by mid-2020. TDI have partnered with Coventry-based Company RDM who will manufacture the vehicle once the design is complete.

A team of experts are also working to develop a new track system.

The Government’s Local Growth Fund through the Coventry and Warwickshire Local Enterprise Partnership (CWLEP) has contributed £2.46 million towards phase one of the research and design of the prototype and £12.2 million has been secured from the West Midlands Combined Authority (WMCA) Devolution Deal to undertake the research and development required to prove the VLR concept.

The WMCA has also allocated specialist resource from Transport for West Midlands to provide technical support, advice and guidance to the project team as the scheme develops.

Dr Darren Hughes, WMG, University of Warwick comments:

“The Coventry light-rail system will be innovative in bringing together technologies from a number of sectors to deliver a low-cost environmentally-sustainable public transport solution for the City of Coventry. Seeing the 3D simulation and envisaging how it will look within Coventry makes us look forward to building the first vehicle that will be ready for testing at a test track facility during 2020.”

Councillor Jim O’Boyle, cabinet member for jobs and regeneration, comments:

Councillor Jim O’Boyle, cabinet member for jobs and regeneration, comments:

“Very Light rail is a fantastic innovation and it has the potential to transform the way people travel. It will be much more affordable to install than traditional trams, take up far less road space, be able to run alongside traffic and our ultimate aim is that it doesn’t require a driver so it can be a frequent service.

“Coventry has a rich traditional of vehicle manufacturing and now we are leading the way in future transport too. This Very Light Rail work, combined with our work on driverless and connected cars puts us right at the forefront of creating new, ground breaking solutions for future transport needs. They will be safer and more environmentally friendly and I hope go on to provide good job opportunities for local people too.”

Jonathan Browning, chair of the CWLEP, comments:

“Coventry and Warwickshire is at the forefront of battery technology and this exciting scheme emphasises our skills at leading the way in innovation.

“This new technology will bring more jobs and investment to Coventry and Warwickshire and it underlines the value of partnership working to boost the area’s economy.

“It is great news that the prototype of the Very Light Rail vehicle will be built ahead of Coventry being UK City of Culture in 2021 when the area’s profile will be boosted on a global stage.”

Researchers set an autonomous vehicle communications record using 5G - a movie’s worth of data sent in seconds

Researchers in WMG at the University of Warwick have set a new 5G communications speed record to a “Level 4” low speed autonomous vehicle in the pioneer 28 GHz millimetre wave band. They hit 2.867 gigabits per second in over-the-air transmissions, which is nearly 40 times faster than current fixed line broadband speeds. It is equivalent to sending a detailed satellite navigation map of the United Kingdom within a single second, or the full contents of a high definition blockbuster film in less than 10 seconds.

However this crucial wireless communications technology is not just being designed to deliver HD content to in-car entertainment systems, but it will allow autonomous vehicles to rapidly share large quantities of data with each other and with traffic management systems. This will include precise 3D road maps created by LiDAR (like radar but it uses laser light instead of radio waves), high definition video images of the vehicles surroundings, and traffic information.