WMG News

Flagship Coventry transport project takes a major step forward to net zero

- Real-world urban highway demo site of innovative rail track system for Coventry Very Light Rail (CVLR) unveiled on University of Warwick campus

- Testing facility will allow simulation of various scenarios, enabling active engagement with key stakeholders including utility companies and city transport planners

- WMG and Ingerop engineers have capitalised on advanced material and manufacturing processes developed over recent years

The Coventry Very Light Rail Project (CVLR) has taken a major step forward, as Coventry City CouncilLink opens in a new window and WMG, at the University of Warwick, launch a real-world demo site for its light rail track system.

The Coventry Very Light Rail Project (CVLR) has taken a major step forward, as Coventry City CouncilLink opens in a new window and WMG, at the University of Warwick, launch a real-world demo site for its light rail track system.

The site, based at WMG, University of Warwick, gives stakeholders a snapshot of what’s to come in Coventry, when the first phase of the city route commences.

Using advanced material and manufacturing processes, researchers and engineers at WMG have worked alongside track-design experts at IngeropLink opens in a new window to create, design and build the demo site including the unique track system, which is not only more affordable to install but also enables rapid installation - minimising disruption to local properties and businesses.

The track form, designed to sit within the top 30cm of existing highway surfaces, is easy to install and can be removed rapidly; significantly reducing clashes with utilities and potentially saving millions of pounds otherwise spent on excavation and moving gas, electrical and telecommunication systems when installing more traditional track forms. With installation costed at approximately £10m per km, the track is significantly cheaper compared to current tram tracks which can cost upwards of £25m per km, and significantly more in city centre locations.

The new track has been developed in parallel to a zero-emission, battery-powered lightweight shuttle vehicle created in partnership with TDi. The vision of Coventry Very Light Rail is that as technology matures it will become autonomous and work similarly to the London Underground system, where service is frequent and passengers can hop on and off.

The vehicle itself is lightweight, and there will be no overhead power supply along the route, significantly reducing infrastructure costs, complexity and visual impact on the city-scape.

Councillor Jim O’Boyle, Cabinet Member for Jobs, Regeneration and Climate Change, said: “This new track test site is a key part of our work to demonstrate the viability of the breakthrough technology in this track. In a world first, we’re aiming to keep pipes and cables in the ground, lowering installation costs and making Coventry Very Light Rail possible in our city and across the country.

“Coventry Very Light Rail will form the backbone of our future transport network, but we’re investing in many projects to make our city’s transport cleaner, greener and more convenient for residents. Coventry Very Light Rail will fit seamlessly with our plans to be the UK's first all-electric bus city and our plans to continue to provide more on-street electric charge points than anywhere outside London.”

Following installation at the University of Warwick, Coventry City Council will install test track at its Whitley Depot waste facility to test it with heavy goods vehicles, and also at the Very Light Rail National Innovation Centre (VLRNIC) in Dudley, where vehicle testing is currently taking place. The installation will form part of the facility’s 15m radius loop, built to test the CVLR prototype vehicle’s cornering system and will enable full system integration testing to be undertaken.

Dr Christopher Micallef, Principal Engineer at WMG, University of Warwick comments: “The University of Warwick urban track demonstration site provides an ideal scenario to prove-out the installation methods of the novel track system. The site will enable various competing sub-systems such as the encapsulation and pavement systems to be trialled to further explore the advantages and challenges.

ideal scenario to prove-out the installation methods of the novel track system. The site will enable various competing sub-systems such as the encapsulation and pavement systems to be trialled to further explore the advantages and challenges.

“The site includes features such as water drainage gullies, buried utilities and a sewage access chamber to ensure that solutions to these real-world complexities can be explored. After the first phase, which is all about the track installation process, the site will be further utilised to allow various scenarios to be simulated and enable active engagement with key stakeholders such as utility companies, materials and subsystems supply chain and city transport planners. Eventually it could provide a facility to train the next generation of track installation teams.”

Andy Street, Mayor of the West Midlands, said: “This very light rail project is a fantastic demonstration of collaboration across our region – whether it’s the development at Dudley, this new test track at Warwick University or soon enough the first route in Coventry city centre.

“The West Midlands Combined Authority is investing £71.5m into very light rail. Designing and building a light rail service rapidly and at a fraction of the cost of regular Metro lines has the potential to transform our public transport network. It is also a great example of cutting edge innovation that can help us to meet our #WM2041 net zero commitment and tackle the climate emergency. Our region is ideally placed to become the home of the green industrial revolution.”

Coventry Very Light rail is being led by Coventry City Council and has received funding from the West Midlands Combined Authority, the Coventry and Warwickshire Local Enterprise Partnership and Coventry City Council.

-ENDS-

Sustainable aviation collaboration wins best UK industry-academia partnership for 2022

- University of Birmingham and Rolls-Royce win Bhattacharyya Award 2022 for their work on Advanced Metallic Alloys

- Award-winning partnership recognised for advancing sustainable aviation for the future

The Royal Academy of Engineering and WMG, at the University of Warwick, have announced the University of Birmingham’s partnership with Rolls-Royce on Advanced Metallic Alloys as the winner of the Bhattacharyya Award for 2022. The Award, which carries a £25,000 prize, has been presented in recognition of an exemplary academia-industry partnership that has helped to lead the UK’s work on creating safe, efficient, and sustainable aeroengines for the future.

Advanced Metallic Alloys as the winner of the Bhattacharyya Award for 2022. The Award, which carries a £25,000 prize, has been presented in recognition of an exemplary academia-industry partnership that has helped to lead the UK’s work on creating safe, efficient, and sustainable aeroengines for the future.

The Bhattacharyya Award is funded by the Department for Business, Energy and Industrial Strategy and was created to encourage more private and academic entities to collaborate, as a tribute to the late Professor Lord Kumar Bhattacharyya KT CBE FREng FRS, Regius Professor of Manufacturing at the University of Warwick and founder of WMG.

Dating back to 1989, the University of Birmingham-Rolls-Royce collaboration has enabled transformative advances in engine efficiencies - directly addressing environmental concerns, while also saving billions of pounds over 30 years of large fleet activity. Their partnership is at the heart of activities to develop and deliver the new engine technologies required to achieve or improve upon the ACARE Flightpath 2050 targets of 75% reduction in CO2 emissions and 90% reduction in NOx.

This industry-academia collaboration has seen extensive, continuous research into processes that are critical for maintaining a competitive and safe aerospace industry and cementing the UK as a leader in aeroengine architectures. These processes have included the enhancement of titanium and nickel disc alloys, development of new titanium aluminide alloys and single crystal turbine blade alloys for jet engines – all using advanced process and materials modelling.

Additionally, the partnership’s established High Temperature Research Centre is ideally placed for developing future aerospace technologies, including solutions for electrification of flight, hydrogen-powered aeroengines and use of alternative, sustainable aviation fuel.

Together, the University of Birmingham and Rolls-Royce partnership has significantly advanced metallurgy in the UK, built new infrastructure and promoted relationships between UK universities for over three decades. The partnership has also focused on developing future talent, having trained over 100 doctoral students in Birmingham who have joined Rolls-Royce as materials and manufacturing specialists.

Paul Bowen FREng, Feeney Professor of Metallurgy/Deputy-Pro-Vice-Chancellor (Industrial Partners) and Rolls-Royce University Technology Centre Director at the University of Birmingham, said: “Our team is immensely proud to win this award on behalf of two generations of researchers in our partnership. They have produced safe, efficient aero-engines and have delivered new technologies, new buildings and developed careers. Winning this award is a testimony to the unrivalled support that Rolls-Royce have provided to universities in support of the metallurgical base of the UK.”

Professor Dame Ann Dowling OM DBE FREng FRS, past-President of the Royal Academy of Engineering, and chair of the judging panel for the Bhattacharyya Award, said: “The University of Birmingham and Rolls-Royce’s partnership has contributed immensely to the UK’s aerospace industry. Together, they’ve embodied the spirit of the Bhattacharyya Award by promoting wider collaboration between industry and universities, and in developing the UK’s future talent.”

Margot James, Executive Chair at WMG, University of Warwick, said: “This partnership is a well-deserving winner and demonstrates the power of industry-academia collaboration to address a challenge as timely and as globally significant as sustainable aviation. We hope that this award celebrating Lord Bhattacharyya’s legacy continues to inspire future academics and industry partners to drive further co-operation, creativity, and innovation in the UK.

WMG launches new sustainable elastomer research facility

WMG, at the University of Warwick, has launched its new sustainable elastomer research facility based in the International Institute for Nanocomposites Manufacturing (IINM).

Manufacturing (IINM).

High performance elastomers are essential components in applications across a range of critical sectors, most notably for vehicle tyres, but also for footwear, soft robotics and automation.

However, the high durability of conventional rubbers also results in them being extremely difficult to recycle at the end of their service life, with many simply being incinerated and buried in landfills. The need for new and sustainable elastomer technology is becoming more urgent as society transitions towards fully electric vehicles, which are currently heavier and can cause tyre wear up to 30% faster. Tyre wear emission is accumulated as the second largest microplastics pollution globally.

The main scientific focus of the new facility is to bring together state-of-the-art research from across rubber composite processing and synthetic polymer chemistry - including manufacturing technology, multiscale characterisation, and prototype sustainable rubber products.

Capabilities within the facility include a twin-roll mill for rubber compounding; automated compression moulding and moving die rheometer (MDR); abrasion testing; and a new dynamic rubber process analyser (RPA), which enables advanced analysis of rubber networks over a temperature range of -40 °C to 232 °C, and a wide frequency range, as well as unique rheological characterisation at large amplitude oscillatory shear (LAOS).

Within the IINM there is also a wet chemistry laboratory designed for new formulation development, and rubber and nanoparticle functionalisation, as well as polymer characterisation and testing laboratories to support sustainable elastomer research and development.

Dr Chaoying Wan, Reader of Functional Polymers and Nanocomposites at WMG, University of Warwick explains: “Our new RPA has the capacity of a wider temperature range - it is the only one in the UK, and one of only a few in the world. This function is extremely useful for evaluating elastomer materials as well as for advanced scientific analysis. With support from the High Value Manufacturing Catapult, we are excited to be furthering our research towards extending the functionality of rubber materials and making the products recyclable and sustainable at end-of-life.”

Projects currently underway in the new facility include integrating self-healing properties which result in improved safety and extended lifespan for tyres; stretchable sensors; and investigating other rubber products to enhance the durability of rubbers by the addition of nanofillers, including graphene, and recycling of rubbers for road and pavement uses.

Projects currently underway in the new facility include integrating self-healing properties which result in improved safety and extended lifespan for tyres; stretchable sensors; and investigating other rubber products to enhance the durability of rubbers by the addition of nanofillers, including graphene, and recycling of rubbers for road and pavement uses.

Find out more about WMG’s Nanocomposites research here: Nanocomposites (warwick.ac.uk)

Contacts:

Dr Chaoying Wan – Rubber Chemistry and Dielectric Elastomer Technology

Professor Tony McNally - Composites of Elastomers and Nanomaterials

Specialist electric motorcycle project hailed a great success

Today (Tuesday 12th July 2022), marks the official completion of the Triumph TE-1 electric development project, a unique four-way partnership between WMG at the University of Warwick, Triumph Motorcycles, Williams Advanced Engineering and Integral Powertrain Ltd e-Drive Division.

Today (Tuesday 12th July 2022), marks the official completion of the Triumph TE-1 electric development project, a unique four-way partnership between WMG at the University of Warwick, Triumph Motorcycles, Williams Advanced Engineering and Integral Powertrain Ltd e-Drive Division.

The TE-1 project was funded by the Office for Zero Emission Vehicles through Innovate UK, and was set up to create ground-breaking developments in specialist electric motorcycle engineering and innovative integrated technology design. The project provides an input into Triumph’s future electric motorcycle offering, driving innovation, new standards, capability, and new intellectual property, whilst enhancing the credibility and profile of British industry and design.

Driving lower environmental impact transportation, and delivering against the UK’s focus on reducing emissions, the project also aimed to develop strong, commercially viable and sustainable partnerships with UK industry manufacturers and supply chains, whilst building expertise and capability within the UK workforce.

Nick Bloor, CEO, Triumph Motorcycles, said: “We are incredibly proud to be able to share such positive outcomes from the completion of Project Triumph TE‑1, where the prototype demonstrator has exceeded many of our initial targets and expectations. Everyone on the team is thrilled with the results we have achieved with our partners, and how the outcomes of the project will feed into the electric future to come from Triumph.”

Released today, the final testing results show how the TE-1 prototype has delivered on all targets and objectives following an extensive live testing programme which involved numerous assessments of the bike’s performance on a rolling road as well as on track.

WMG’s role in the project was to provide electrification expertise, and the critical vision to drive innovation from R&D to commercial impact, through modelling and simulation based on future market needs.

Highlights from the testing results include a standing start acceleration of 0-60mph in 3.6 seconds, peak power of 130kW (177PS / 175bhp) as well as peak torque of 109Nm (80 lb-ft), a 20-minute charge time (0-80%) and a 161km / 100-mile range based on official testing and projections. At 220kg (485 lb), the TE-1 prototype is also lighter than the equivalent electric bikes available currently by up to 25%.

20-minute charge time (0-80%) and a 161km / 100-mile range based on official testing and projections. At 220kg (485 lb), the TE-1 prototype is also lighter than the equivalent electric bikes available currently by up to 25%.

Professor David Greenwood, CEO of the High Value Manufacturing Catapult at WMG, University of Warwick, explained: “To meet our ambitious emission reduction targets in the UK we will have to rethink the way we travel, not only transitioning from ICE to electric propulsion vehicles, but also encouraging a modal shift away from private cars. Electric two wheelers have a pivotal role to play in the transport revolution as a zero-tailpipe emission option.

“In our partnership with Triumph, WMG used our research experience in electrification to demonstrate manufacturers can deliver products with a lower emission burden as well as outstanding performance-offering customers an EV that is great fun to ride.”

Read more about WMG’s Transport Electrification research here: Energy (warwick.ac.uk)

University of Warwick proposes new quality and safety regulations report for micromobility vehicles

• Legal framework proposed by researchers at the University of Warwick lays out how future micromobility vehicles such as eScooters could be designed and operated in the UK by mid-2023.

• New standards would require manufacturers to develop safer and better quality vehicles.

• The roadmap proposes new powers of enforcement to deter antisocial and illegal use.

• Conclusions were drawn from a wide-ranging consultation with over 100 organisations.

The UK is the last major Western economy not to legislate ‘Powered Micro Vehicles’. The University of Warwick wants to change that and has proposed a new set of regulations for allowing micromobility vehicles, such as e-scooters to operate legally in the UK. The report looks at ways to improve the quality and safety of models available, as well as providing clear guidance for authorities to deal with unsafe behaviour.

WMG researchers at the University of Warwick, with support from Cenex, has published ‘Micromobility, a UK roadmap’. It is a regulatory framework that provides a set of standards for eScooters, a cargo variant and other micro vehicles, to be operated legally in the UK, which is aimed at supporting regulatory change through parliament.

100 organisations representing road users, safety groups, transport authorities and industry have helped shape the roadmap. If the roadmap was adopted, the public could legally operate eScooters and other micromobility vehicles by mid-2023.

Micromobility is a key part of achieving net-zero emissions for transport. For many journeys, particularly short journeys, walking or using micromobility are much better for the environment than using a car. The economic benefits are also compelling both in the cost of the vehicle and the manufacturing opportunities. Without change many manufacturers may leave the country.

The key recommendations of the roadmap are:

• The creation of a new vehicle category “Powered Micro Vehicles” and three initial new vehicle types in the category: eScooter, Light Electric Cargo Vehicle, Electric Light Moped.

• Specific standards and regulations for each vehicle type, including speed limits and weight limits.

• Vehicles must be registered and be visually identifiable.

• Cardinal design requirements around minimum wheel size and redundancy of braking systems, so there is a secondary method of slowing the vehicle down.

• Daytime running lights, a sound emitter and indicators are required to improve visibility for current road users.

• No use on the pavement in any circumstance, and instead use on roads and cycle-ways.

• Minimum ages for operating the vehicles, and PPE recommendations.

• New powers for local policing and PCSOs in England and Wales, to fine breaches and illegal use.

Lead author John Fox, Programme Director at WMG at the University of Warwick, said “The purpose of the 'Micromobilty, a UK roadmap’, is to provide regulations on how powered micromobility vehicles could be designed and operated in the UK.

“It’s important that these vehicles are high quality, safe, and legal. They can provide a low-carbon mobility option which is available to everybody, allowing us to make choices about how we travel, and stimulating future innovation which will accelerate a market for UK manufacturers.”

Robert Evans, CEO at Cenex comments, “In order to lower emissions from transport, it is crucial we find a way forward that allows the UK micromobility market to grow sustainably and safely for all.

“The growth in e-bike use and the popularity of e-scooter trials have demonstrated that electric powered micro vehicles will have a significant role in our future transport systems. The right legislation and regulations must enable this whilst minimising any potential negative impacts.

“Cenex is proud to have supported WMG in this work and looks forward to seeing the benefits and impacts.”

Richard Dilks, Chief Executive at CoMoUK, said “Further to our recent letter to the Transport Secretary, CoMoUK sees a clear need for legislation to fill the void we currently have over micromobility options such as escooters beyond the welcome rental scheme trials. We welcome the announcement from the Transport Secretary that the Government intends to legislate. We need all the options we can lay our hands on to reduce our over-reliance on private cars in particular and motorised mileage in general, and proposals such as these help put flesh on the bones of how we can fill the gap.”

Adam Norris, Founder of Pure Electric, said, “As Europe’s largest e-scooter retailer we are working hard to support the Government with bringing in legislation. The UK still remains the only large economy not to have legalised and regulated private e-scooters. It is frustrating that the UK has fallen behind the rest of Europe, however, the detailed work from the experts at the University of Warwick demonstrates that the UK has the potential to become a world leader in micro-mobility.”

Over the course of six months, the researchers held five workshops with over 100 organisations represented. Participants came from a broad range of stakeholders, including user groups – such as road safety groups, charities and cycling groups - service providers, vehicle developers and manufacturers, local and regional transport authorities, and policymakers. These workshops examined a range of options covering vehicle types, vehicle safety, maximum speeds, to try and form a consensus.

• The roadmap is available online: short version and long version

• The image (taken on private land) is courtesy of Pure Electric.

WMG is hosting its 2nd micromobility event on 9th June where the roadmap will be debated by key industry stakeholders. The event will also feature the latest data from industry and technology experts, with the opportunity to trial some of the latest micromobility solutions

The University of Warwick supports RIFT Technology with a greener cost-effective electric motor

A cheaper and more environmentally friendly electric motor for electric vehicles is a step closer to market with the support of WMG at the University of Warwick.

WMG has provided valuable knowledge and expertise in developing a UK focused, cost-effective production and supply chain for RIFT (Reduced  Induction Field Torque) Technology’s development of RIFT-10; a design for electric motor drives that reduces copper and magnet weight reduction by around 50% and lower cost by 75%.

Induction Field Torque) Technology’s development of RIFT-10; a design for electric motor drives that reduces copper and magnet weight reduction by around 50% and lower cost by 75%.

The aim of the project was to help RIFT Technology; an R&D company bringing a product to market for the first time, advance RIFT-10 to a higher manufacturing readiness level (MRL 7), to get the motor closer to production, by rooting the supply chain in the UK, rather than abroad (given the disruption to supply caused by the pandemic) and supporting production of trial units.

WMG, is committed to delivering UK economic impact and achieving net-zero by supporting industry in accelerating new concepts to commercial reality. This supports the University of Warwick’s approach to sustainability - the Way to Sustainable – which focuses on the real-life implications of creating a sustainable future and the practical challenges of getting there - prioritising research expertise, sustainability in the curriculum, and developing solutions for the benefit of industry and society.

The team of experts at the University has facilitated the RIFT-10 project to deliver on creating revenue, jobs, CO2 reduction, and supply chain growth in the UK.

RIFT Technology has developed the RIFT 10-30 kW motor (RIFT-10) by taking an exciting innovation from their sister business (RIFT Actuators) and working with APC and the Niche Vehicle Network to get the motor to working prototype stage (installed on a G-Whiz). The novel electric motor configuration is proven to generate 10-30kW of power, torque from 0-400Nm and up to 10,000RPM as demonstrated with a prototype vehicle.

The RIFT 10 motor demonstrated unique advantages over conventional EV motors:

Environmental benefits of the project:

· The low sales cost and attractive features of RIFT-10 enable greater/earlier market adoption of EUV’s, resulting in a reduction of CO2 production over ICE vehicles.

· A RIFT-10 weight saving and efficiency over competing EV motor designs increase vehicle range, resulting in less energy usage over alternatives.

· With RIFT-10, equivalent power output is achieved using fewer raw materials (i.e., 85% reduced copper weight and ~85% reduced magnet volume), resulting in less earth material usage as well as fewer material costs.

· Less materials usage results in an estimated 75% reduction in CO2 produced during manufacture. Planned production efficiencies also lead to further CO2 reductions. An estimated 612,000 Tonnes of CO2 would be saved by year 5.

· Development of an EV motors supply chain in the UK for a UK and EU market reduces international shipping of components thus reduces related CO2 production.

Social benefits of the project:

· RIFT-10 creates/safe-guards 50+ much needed and good-quality manufacturing, sales, administration and R&D jobs in the Malvern area with an estimated X14 more UK jobs across the supply chain (over 5-years).

· Growth of RIFT-10 addresses the government’s priority area of ‘Smart Cities’ by allowing smart monitoring of vehicle fleets efficiency performance, usage and other data points. The use of the Internet of Things and resulting analysis can only be as strong as the data input. Traditional alternatives offer no smart functionality.

James Black, WMG Innovation Manager at the University of Warwick said, “The Covid-19 pandemic has been particularly difficult for SMEs and R&D-focused organisations that have previously relied on face-to-face networking events to find new partners, investors, and customers.

“WMG’s network means we’re in a great position to connect UK companies together to help them accelerate their product to the market, and we’re delighted that RIFT Technology has benefited from our extensive background for practical supply chain solutions that have delivered economic and societal value to the project.”

James O’Donnell, Technical Manager from RIFT Technology said, “As a research and development company bringing a product to market for the first time, RIFT Technology needed to bridge the gap between prototype and small-scale production. We had to answer difficult questions such as what to make and what to buy, high level questions such as how to develop a supply chain strategy and practical questions such as how best to select suppliers.

“With a unique blend of academic expertise and industrial experience from the University of Warwick, WMG’s Supply Chain and Operations Group were able to support us in our journey.”

The project took place during the pandemic, meaning several online workshops were carried out targeting topics such as strategic management, supplier selection and decision-making, and end-of-life strategies.

For further stories, click here.

ENDS

4 April 2022

Partnership between WMG and The Blair Project to deliver electrification skills training in the north

WMG has partnered with The Blair Project, a social enterprise based in Manchester, to deliver the Emerging Skills Project in the north, a programme funded by the Department for Education (DfE).

The Emerging Skills Project will create a highly skilled workforce that will enable industries including automotive, energy and food and drink, to take advantage of electrification and hydrogen-power to deliver Net Zero.

The course provided by The Blair Project will specifically address technologies related to electric vehicles. This will include the assembly and maintenance of battery modules and packs, recycling and second life, the manufacturing and installation of motors, drives and power electronics and the designing and testing of vehicle and software systems.

Developed in conjunction with businesses who were invited to a series of workshops with DfE, the course will directly respond to the demand for wider adoption and deployment of transport electrification technologies.

The course will be held at the new Manchester Innovation Activities Hub (MIAH) – launching in Spring 2022. Dedicated to the rapid upskilling, reskilling and retraining of more than 5,000 local residents over the next five years, MIAH is set to become a centre of excellence in Greater Manchester and a hub for electrification skills training in the north.

Ben Silverstone, Associate Professor and Head of WMG Skills Centre, said:

“As important as it is to train up the younger workforce in green tech, there is a significant workforce primed for reskilling now. It’s the combination of both that will ensure we are well-equipped to meet the UK’s ambitious Net Zero targets.

“We are pleased to partner with an organisation like The Blair Project to deliver the Emerging Skills Project, meeting the UK-wide demand for electrification skills and giving people in the region the opportunity to upskill or reskill in this area.”

Nile Henry, Founder and CEO of The Blair Project, said:

“The UK is facing a huge skills gap in green tech, particularly electrification, and this is only set to increase as we power towards Net Zero and the demand for a highly skilled workforce grows. Partnering with WMG to become a delivery partner for the Emerging Skills Project is a huge milestone for The Blair Project, and it’s brilliant to see this focus from Government on upskilling adults in green tech.”

WMG welcomes Victoria Prentis MP, Minister of State at the Department for Environment, Food and Rural Affairs (DEFRA)

WMG was pleased to welcome Farming Minister Victoria Prentis yesterday (Thursday 20th January).

The Minister was welcomed by WMG Executive Chair, Margot James, and given a tour of the Innovate UK-funded Natural Light Growing Centre and DEFRA-funded vegetable gene bank research centre, run by the School of Life Sciences, at the University of Warwick’s Wellesbourne campus.

DEFRA-funded vegetable gene bank research centre, run by the School of Life Sciences, at the University of Warwick’s Wellesbourne campus.

The delegation then headed to WMG, on the University of Warwick campus, where they were given a presentation from Professor Robert Harrison on horticultural robotics and how they can support on a range of agricultural tasks. They then met with Professor Kerry Kirwan, who explained more about water treatment using recycled carbon fibre sheets.

Finally Dr Mark Swift, Head of SME Programmes, explained more about the SME support programme where WMG has helped the food and drink sector apply digital manufacturing techniques.

Margot James, executive Chair at WMG, University of Warwick said: "It was a pleasure to have Minister Victoria Prentis to visit us today, we were delighted to share the cutting edge research we are doing in collaboration with the agriculture and horticulture industries.

“These are vital sectors to the UK economy but there is vast potential to improve using automation, AI and digital manufacturing, as well as new growing practices being researched by our Life Sciences department."

Farming Minister Victoria Prentis, added: “It was great to visit the University of Warwick, which is making significant strides to ensure agri-robotics can be a reality for farmers and growers in the UK.

reality for farmers and growers in the UK.

“We know how important it is for the industry to maximise productivity and yields. We are putting in place a series of initiatives – from the Farming Investment Fund, to the Farming Innovation Programme – to support the development and uptake of technology which can boost food production, productivity and the environment.”

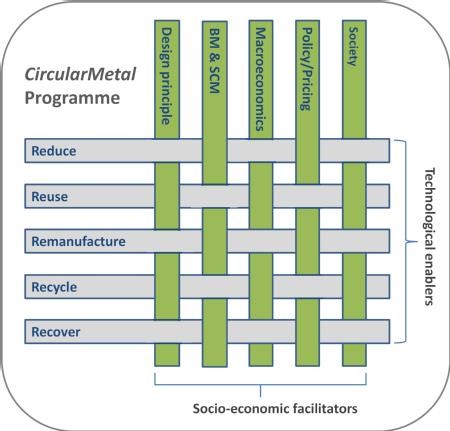

UK aims to be the first Country in the world to circulate steel and aluminium fully, supported by the CircularMetal programme

§ The UKRI National Interdisciplinary Circular Economy Research Programme aims to create a sustainable circular economy for lots of different industries, including metals

§ Metals and metal products create 10-20% of all the world’s harmful impacts, such as greenhouse gas emissions and pollution and energy consumption; we cannot do without goods made from metals; so we must learn how to make their use circular, i.e. extend their lifetimes and increase their repair, re-use and recycling

§ The Interdisciplinary Centre for Circular Metals aims to accelerate the transition from the current largely take-make-waste linear economy to full metal circulation by conducting high quality research and innovation through a systems approach. Its ambition is to make the UK the first country to realise full metal circulation (at least for the high-volume metals – steel and aluminium) by 2050. This will form an integral part of the government’s efforts to achieve Net Zero by 2050

§ To deliver the CircularMetal research programme, WMG at the University of Warwick will conduct inter-disciplinary research on steel production, recycling technologies, remanufacturing of steel components, and artificial intelligence in scrap separation

The metal industry in the UK employs 230,000 people, and directly contributes to £10.7bn to the UK GDP. A truly interdisciplinary academic team will research how to make a sustainable circular economy for high-volume metals, with WMG at the University of Warwick focussed on steel.

The metal industry in the UK employs 230,000 people, and directly contributes to £10.7bn to the UK GDP. A truly interdisciplinary academic team will research how to make a sustainable circular economy for high-volume metals, with WMG at the University of Warwick focussed on steel.

The UKRI has established five Interdisciplinary Circular Economy Centres in the UK, coordinated by the Circular Economy Hub (CE-Hub), which together form the NICER Programme, a £30 million investment on research aimed at developing a circular economy in the UK, One of these CECs is CircularMetal, the Interdisciplinary Centre for Circular Metals, led by Brunel University London, with partners from WMG, University of Warwick, University College London and Loughborough University.

The ultimate aim of the group is to make the UK fully circulate all their steel and aluminium, thereby minimising or eliminating the extraction of raw materials and the production of waste.

WMG, at the University of Warwick, will specifically research steel, including opportunities for reuse and the technologies for scrap sorting to increase recyclability, working with partners in the project on business model supply chains and the economy and policy surrounding them.

The Interdisciplinary Centre for Circular Metals is a four-year project, which started in January 2021 thanks to £4.2m funding from UKRI. Discussions within the team on strategies to reuse / recycling / reduce / remanufacture / recovery and the technological barriers are on-going with input being provided to government groups.

Professor Claire Davis, from WMG, University of Warwick comments:

“To be part of the Interdisciplinary Centre for Circular Metals is incredibly exciting, especially in light of COP26, as the potential that a circular economy for metals could have towards meeting goals of sustainability and furthermore preventing climate change.

“At WMG, University of Warwick we hope to research how technology can help us to reuse and recycle steels, for example, understanding the end of life condition of steel components to determine whether and how they can be used, and using artificial intelligence to increase scrap recyclability.

“If metals can be fully recycled and reused the need to extract raw materials to make them in the first place could be eliminated, and the current workforce in the metals industry could be reskilled to work in recycling and repurposing metals.”

Professor Brian Cantor, Deputy Director, The UKRI Interdisciplinary Centre for Circular Metals BCAST, from Brunel University comments:

“Metallic materials are the backbone of manufacturing and the fuel for economic growth. They underpin the competitive position of almost every industrial sector and, including metal manufacture and downstream product processing, they collectively contribute 15-20% of all greenhouse gas emissions, pollution and energy consumption. Transformation of the metals industries from the current largely linear economy to a circular economy will, therefore, play a critical role in delivering the government’s industrial strategy for clean growth, doubling of resource productivity and reaching net zero carbon emissions in 2050.

“CircularMetal is focused on helping the UK become the first country to realise full metal circulation, concentrating on the two main bulk metals aluminium and steel, and the three main industrial sectors of transport, construction and packaging.”

ENDS

22 DECEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/picture1.jpg

Caption: A graphic of the factors considered in the CircularMetal programme

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/picture2.jpg

Caption: The building the Warwick arm of the CircularMetal project are based in at WMG, University of Warwick

Credit: WMG, University of Warwick

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

New city climate change commission to drive forward low carbon targets

Senior leaders from organisations across Coventry met today to help shape and move forward actions to reduce the impact of climate change.

Senior leaders from organisations across Coventry met today to help shape and move forward actions to reduce the impact of climate change.

A new Coventry Climate Change Board will meet regularly to share policies, plans, good practice and work together collaboratively in an effort to keep the city on track for a zero carbon future.

The Board is chaired by Margot James, the former minister for culture, communications and creative industries and Executive Chair for WMG at the University of Warwick.

Senior representatives from businesses located in the city, public service providers and community organisations will work together on plans for the future of the city.

Margot James, Executive Chair at WMG, University of Warwick said:

“I want to be involved in the Board because I believe organisations must collaborate if we are to reduce our carbon footprint. This applies to the public sector and the commercial sector, charities and voluntary groups of all sizes.

“At WMG we are working with industry to develop solutions that will have a long-term impact on climate change, including electrification of transport from passenger cars to very light rail vehicles, and developing sustainable manufacturing processes.

“I want this Board to make a difference and cut through any blockages preventing action within and between the organisations we represent to develop collaborative solutions to sometimes complex issues.”

“Ultimately, we need to set out actions and win hearts and minds. We also want to communicate how residents of all ages can be involved. It’s about the wellbeing of future generations in the city.

“I expect more organisations will be invited to join the Board in the coming months.”

Cllr Jim O’Boyle, Cabinet Member for Jobs, Regeneration and Climate Change at the Council, added: “As a local authority we are applying innovative approaches and technologies but no one organisation can work alone to address a low carbon future.

Cllr Jim O’Boyle, Cabinet Member for Jobs, Regeneration and Climate Change at the Council, added: “As a local authority we are applying innovative approaches and technologies but no one organisation can work alone to address a low carbon future.

“I hope that as a Board and a combined group of organisations we can come together to identify new ways of working together.

“I’m sure that we will be able to deliver a range of cost-effective schemes to invest in a more sustainable future for the city.”

§ Last week Coventry held a COP26 Regional Roadshow highlighting a Transport Expo which was funded by the UK Government to celebrate and showcase the city’s innovative work in addressing climate change and decarbonising transport in the city.

§ Coventry has an A-rated CDP energy performance rating which is a national standard that is independently verified.

§ It has the highest number of electric charging points per head of population outside of London and will be the first city with an all-electric bus fleet from 2025.

The Council is investing in 5,000 solar panels on 41 Coventry buildings with public funding and there are many other schemes that city partners are supporting.

ENDS

17 NOVEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/171121coventryclimatechangeboard_36.jpg

Caption: Front, Cllr O’Boyle with Margot James and partners from organisations across Coventry congregating outside the Prof. Lord Bhattacharyya building home to NAIC the National Automotive Innovation Centre at WMG, University of Warwick

Credit: Mark Radford Photography

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/171121coventryclimatechangeboard_29.jpg

Caption: The board congregating at WMG, University of Warwick

Credit: Mark Radford Photography

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/171121coventryclimatechangeboard_08.jpg

Caption: Margot James, Executive Chair of WMG, University of Warwick talking to the board

Credit: Mark Radford Photography

https://warwick.ac.uk/services/communications/medialibrary/images/november_2021/171121coventryclimatechangeboard_03.jpg

Caption: Cllr Jim O’Boyle talking to the board

Credit: Mark Radford Photography

For further information contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk