WMG News

Collaborative project wins prestigious industry award

Researchers at WMG at the University of Warwick and the University of Victoria in Canada, have won the inaugural Synthos Rubber Circularity Award.

Researchers at WMG at the University of Warwick and the University of Victoria in Canada, have won the inaugural Synthos Rubber Circularity Award.

The international competition was launched to encourage cutting-edge ideas and solutions that will significantly improve the environmental performance of synthetic rubber-based tyre compounds, aligning with the sustainability objectives of the global automotive and tyre industries.

Synthos, a global leader in synthetic rubber, praised the two universities for their breakthrough technology research concept and global collaborative approach.

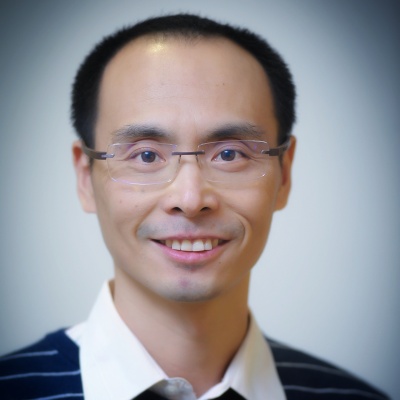

Professor of Nanocomposites at WMG, University of Warwick, Chaoying Wan explained: “Rubbers are ubiquitous materials in modern society and have played important roles across transportation; construction; oil and gas; biomedical devices; sports and electronics.

“As the key component to connect the vehicle to the road the performance of the tyre, including its rolling resistance, abrasion resistance and wet grip, directly determines the fuel efficiency, wear emission and safety.

“The emerging EVs and SUVs have raised increasing higher demands for performance that challenge the current technology. This new partnership, with Synthos Synthetic Rubber and the University of Victoria, will enable us to innovate rubber chemistry and develop functional rubber nanocomposites manufacturing technologies to address performance challenges. The new technology will also innovate traditional rubber systems to be actively recyclable.”

Matteo Marchisio, Vice President, Synthetic Rubber, stressed the importance of investing in research and development of sustainable rubber and tyre materials. “We are very proud of our diverse group of exceptional and talented scientists that make up the Synthos Rubber R&D team. Together with the University of Warwick and the University of Victoria, we see an exciting future in expanding our product development horizons. I firmly believe that by fostering innovation and collaborating with the brightest minds in scientific research, we move not only ourselves but also the entire value chain closer to our goal of carbon neutrality by 2050.”

Synthos Synthetic Rubber R&D Director Dr. Malte Wohlfahrt added, “We congratulate the University of Warwick and the University of Victoria for presenting an impressive research concept that we believe is the best fit for us. However, I also want to acknowledge the excellence of many other entries we received. The Synthos Rubber Circularity Award isn't just about crowning a winner; it's about advancing a culture of innovation. Therefore, we intend to collaborate with and invest in some of the other standout scientists and institutes we’ve had the honor to engage with. Overall, this award has sparked immense inspiration across our entire rubber business and given us much food for thought.”

The university collaborators will receive a three-year funding package to support a dedicated research team. They will also be provided with Synthos rubber materials and access to its state-of-the-art facilities. In addition, scientists from both institutions and Synthos will form a project team to work closely together and leverage the capabilities of all parties in a way that maximises the value of the collaboration to the tyre industry.

Find out more about Nanocomposites research at WMG here: Nanocomposites (warwick.ac.uk)

WMG research helps develop new generation of graphene composites

Researchers at WMG, University of Warwick’s, International Institute for Nanocomposites Manufacturing (IINM) have been working with the team at Versarien plc on a new comprehensive portfolio of graphene and related nanomaterial based thermoplastic polymer compounds and masterbatches.

Researchers at WMG, University of Warwick’s, International Institute for Nanocomposites Manufacturing (IINM) have been working with the team at Versarien plc on a new comprehensive portfolio of graphene and related nanomaterial based thermoplastic polymer compounds and masterbatches.

The new PolygreneTM compounds are expected to have potential commercial applications in areas as diverse as sports equipment, construction products, aerospace and automotive components.

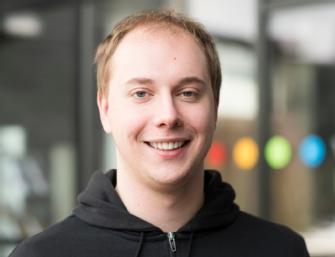

Since 2018, Versarien subsidiary 2-DTech Ltd (2DT), Composites UK member, has funded PhD and postdoctoral researchers to understand the use of its Nanene™ graphene powders and other nanomaterials in thermoplastic systems. Dr David Reinoso-Arenas, the first 2DT funded PhD student, with support from the EPSRC Doctoral Training Programme, worked with Versarien’s Nanene™ materials in thermoplastic elastomer (TPE) systems and joined Versarien full-time last year as part of the team at Versarien’s subsidiary Cambridge Graphene Ltd.

Dr David Reinoso-Arenas, explained: “The new PolygreneTM thermoplastics portfolio is a culmination of my PhD research, some of which is due to be published in peer-reviewed journals. Since then we’ve been able to further develop and test these materials using different nanomaterial fillers and process conditions to fully optimise the resulting product performance. My PhD experience at the IINM and WMG was really enjoyable and enabled me to work closely with industry to ensure that the outputs of my research could be validated and have commercial viability.”

David’s PhD was performed under the supervision of Professor Tony McNally, whose team has an established capability in incorporating a wide range of nanomaterials into bulk polymer systems.

Professor Tony McNally, who leads the Nanocomposites Research Group at WMG, University of Warwick, said: “Working with Versarien over the last few years has given the IINM and WMG access to alternative graphene materials that have shown interesting phenomena when blended in these TPE systems. By tuning the nanofiller loading and optimising process conditions, David’s research showed that exceptional gains can be achieved in mechanical properties across the board (tensile strength, modulus, elongation at break, toughness and abrasion resistance) without compromising any properties. The addition of graphene also highlights improvements in polymer processing which may offer lower energy usage and, therefore, improving sustainability.”

Professor McNally continues to work with Versarien by providing a funded PhD position in 2D material based rubber systems, making use of the IINM’s new state of the art rubber processing and testing capabilities With support from the High Value Manufacturing Catapult (HVMC), WMG has established a world class facility for the study of elastomers.

Dr Stephen Hodge, Versarien’s CEO, added: “We look forward to continuing our collaboration with the IINM and WMG in rubber processing and understanding the interactions of our graphene and other 2D materials in these more complex systems, and hope to be able to demonstrate significant benefits that can impact upon real-world applications.”

Find out more and download technical datasheets here: https://versarienproducts.co.uk/thermoplastics

Find out more about WMG’s Nanocomposites research here:https://warwick.ac.uk/fac/sci/wmg/research/materials/nanocomposites/

WMG announces new partnership with global engineering company

WMG, at the University of Warwick, has announced a new two year research partnership focusing on sustainable high-performance sealing materials.

Researchers at WMG’s Link opens in a new windowInternational Institute for Nanocomposites Manufacturing (IINM), led by Dr Chaoying Wan, will be working with experts at James Walker to develop the next generation of sealing compounds which will be compliant with future per- and poly- fluoroAlkyl substances (PFAS) regulations.

In February 2023, the European Chemicals Agency announced a proposal for the European Economic Area that will effectively lead to a ban on all PFAS materials, due to their persistence in the environment.

This research project will use high quantity techniques to develop and identify novel elastomer compounds that comply with proposed PFAS regulations, for use in critical industrial applications drawing on WMG’s expertise in elastomer and polymer technology.

The new technologies developed will have a high impact on a wide range of industries from transportation, oil/gas, semiconductor to hydrogen storage and wind turbines.

and wind turbines.

Conventional high performance sealing compounds rely on PFAS, as these materials are resistant to extremes of temperature and aggressive chemicals. PFAS are essential to the semi-conductor, aerospace, petrochemical, defence and nuclear industries for example, and there are currently no suitable replacement materials available. Alternative sealing materials are urgently needed to substitute PFAS.

Dr Mike Eason, Technical and Quality Director at James Walker commented: "Industrial dependence on PFAS elastomers is a global issue with supply chain impact already seen. I am delighted that we will work with Dr Wan and her team to identify and develop materials which will help industry be compliant with the proposed regulations. This partnership will accelerate James Walker’s development of seal materials for critical industry. WMG has small scale, advanced, mixing capability, with knowhow regarding nanofillers and polymer science that will allow James Walker to rapidly design, manufacture and screen bench-scale test formulations.

“I believe the combination of James Walker’s history and expertise in critical industrial sealing together with WMG’s state of the art capabilities will enable rapid development and commercialisation of materials. James Walker is committed to developing solutions to the PFAS regulations faced by global industry."

Dr Chaoying WanLink opens in a new window, Reader of Functional Polymers and Nanocomposites at WMG, University of Warwick explains: "Collaborating with James Walker to develop alternatives for PFAS seals is an important and exciting opportunity. Our elastomer research facility is supported by High Value Manufacturing Catapult CentreLink opens in a new window (HVMC), equipped with the latest technology, including a rubber process analyser (RPA) with wide temperature range - it is the only one in the UK, and one of only a few in the world with the capability to simulate dynamic elastomer performance at very low temperature.

“This function is extremely useful to compare differences in formulation design for applications such as high pressure or low temperature sealing. I am very much looking forward to working with the James Walker team on the development of new material options for high performance sealing applications and advancing our knowledge of polymer formulation and performance."

Find out more about WMG’s Nanocomposites research here: Nanocomposites (warwick.ac.uk)

WMG launches new sustainable elastomer research facility

WMG, at the University of Warwick, has launched its new sustainable elastomer research facility based in the International Institute for Nanocomposites Manufacturing (IINM).

Manufacturing (IINM).

High performance elastomers are essential components in applications across a range of critical sectors, most notably for vehicle tyres, but also for footwear, soft robotics and automation.

However, the high durability of conventional rubbers also results in them being extremely difficult to recycle at the end of their service life, with many simply being incinerated and buried in landfills. The need for new and sustainable elastomer technology is becoming more urgent as society transitions towards fully electric vehicles, which are currently heavier and can cause tyre wear up to 30% faster. Tyre wear emission is accumulated as the second largest microplastics pollution globally.

The main scientific focus of the new facility is to bring together state-of-the-art research from across rubber composite processing and synthetic polymer chemistry - including manufacturing technology, multiscale characterisation, and prototype sustainable rubber products.

Capabilities within the facility include a twin-roll mill for rubber compounding; automated compression moulding and moving die rheometer (MDR); abrasion testing; and a new dynamic rubber process analyser (RPA), which enables advanced analysis of rubber networks over a temperature range of -40 °C to 232 °C, and a wide frequency range, as well as unique rheological characterisation at large amplitude oscillatory shear (LAOS).

Within the IINM there is also a wet chemistry laboratory designed for new formulation development, and rubber and nanoparticle functionalisation, as well as polymer characterisation and testing laboratories to support sustainable elastomer research and development.

Dr Chaoying Wan, Reader of Functional Polymers and Nanocomposites at WMG, University of Warwick explains: “Our new RPA has the capacity of a wider temperature range - it is the only one in the UK, and one of only a few in the world. This function is extremely useful for evaluating elastomer materials as well as for advanced scientific analysis. With support from the High Value Manufacturing Catapult, we are excited to be furthering our research towards extending the functionality of rubber materials and making the products recyclable and sustainable at end-of-life.”

Projects currently underway in the new facility include integrating self-healing properties which result in improved safety and extended lifespan for tyres; stretchable sensors; and investigating other rubber products to enhance the durability of rubbers by the addition of nanofillers, including graphene, and recycling of rubbers for road and pavement uses.

Projects currently underway in the new facility include integrating self-healing properties which result in improved safety and extended lifespan for tyres; stretchable sensors; and investigating other rubber products to enhance the durability of rubbers by the addition of nanofillers, including graphene, and recycling of rubbers for road and pavement uses.

Find out more about WMG’s Nanocomposites research here: Nanocomposites (warwick.ac.uk)

Contacts:

Dr Chaoying Wan – Rubber Chemistry and Dielectric Elastomer Technology

Professor Tony McNally - Composites of Elastomers and Nanomaterials

WMG supports innovation in polymer science for a sustainable future

WMG researchers based in the International Institute for Nanocomposites Manufacturing (IINM) have been developing a range of polymer-based solutions for application across several critical sectors, including renewable energy, sustainable transport, and replacement of single use plastics, helping to contribute to a sustainable future.

WMG researchers based in the International Institute for Nanocomposites Manufacturing (IINM) have been developing a range of polymer-based solutions for application across several critical sectors, including renewable energy, sustainable transport, and replacement of single use plastics, helping to contribute to a sustainable future.

Here’s a summary of the key projects.

Renewable Energy: Graphene Enabled All Polymer Solar Thermal Cell

Professor Tony McNally working with Dr Sandeep Kumar in partnership with Senergy Innovations Ltd, has submitted patent applications to the UK Intellectual Property Office that describe 2D material filled polymers for use in Solar Thermal Cells. Critically, the materials developed have very high ‘in-plane’ and ‘through-plane’ thermal conductivity and can be processed using conventional polymer processing methods.

The project was supported by BEIS £11M Energy Entrepreneurs Fund. This scheme is for the development and demonstration of state-of-the art technologies, products, and processes in the areas of energy efficiency, power generation, and heat and electricity storage.

Christine Boyle, CEO of Senergy Innovations Ltd, commented: " Working with the IINM and WMG has allowed Senergy to push the boundaries with innovative technology that has the potential to bring a lot of societal good in sustainability and job creation, also enabling future innovation within the business. Dramatic cost reductions of more than 40% are possible when solar thermal systems are re-engineered with high performance polymers. In 2022 we will work alongside our early customers to showcase how the Senergy solar panels can now reduce the cost of delivering solar hot water and heating to a price point that will finally compete with gas and oil."

Professor McNally said: “We are really excited by this exploitation of our research which has far reaching applications in numerous other sectors, including thermal management in electronic devices and electric vehicles.”

The design for manufacture aspects of the development of the solar thermal cell were supported by the High-Volume Manufacturing (HVM) Catapult and the WMG SME Team.

Sustainable Transport: New Chemistry Enables Conventional Sulphur-vulcanised Tyre Tread Rubbers to Self-heal

Dr Chaoying Wan working with Dr Alan Wemyss in collaboration with Bridgestone EMIA have recently filed a patent application which describes the design and inclusion of dynamic bonds in vulcanised rubbers. This allows the conventional covalent-crosslinked rubber networks to be adaptive to external mechanical damage, self-healable and be reprocessed. The dynamic crosslinking networks also promise excellent mechanical properties and fatigue-resistance that are comparable to conventional rubber vulcanizates.

Dr Raffaele di Ronza, R&D Open Innovation Expert at Bridgestone EMIA commented: “At Bridgestone we have a high focus on sustainability and material technologies to extend tyre life, a key element of our strategy in this field. Through this collaboration with WMG we could explore new solutions that support the realisation of our long-terms targets.”

Dr Chaoying Wan said: “We are delighted with the progress that has been made in improving the sustainability of vulcanised rubber products during our collaboration with Bridgestone. We are now able to further our understanding of self-healing vulcanised rubbers thanks also to the support from WMG and the High Value Manufacturing Catapult which will take us further towards in-depth understanding of elastomer science and new technology development for sustainable elastomer manufacturing.”

Replacement of single-use plastics: Sustainable Bioplastics for Food Packaging Applications

Dr Chaoying Wan and Professor McNally in partnership with Pujing Chemical Industry Co., Ltd., have developed fully biodegradable plastics with the gas barrier and mechanical properties required for food packaging applications. Poly(glycolic acid) or PGA has great potential as a substitute for current single-use plastics used in food packaging applications but with a lower carbon footprint. By blending and promoting interfacial interactions between PGA and other bioplastics, such as PBAT, the team have developed sustainable plastics for food packaging.

In collaboration with Sherkin Technologies UK Ltd., the team have been able to enhance the barrier properties of PGA/PBAT further by crosslinking the outer surface of the films using low energy electron beam treatment.

Dr Bowen Tan, Research Manager (UK), Pujing Chemical Industry Co., Ltd. Stated: “We collaborated with WMG on a research project on the blending of biodegradable plastics for flexible packaging applications. They have provided specialist and a wealth of expertise on plastic processing and modification. WMG is equipped with a wide range of polymer processing and testing equipment which enable our research to be carried out from small to manufacturing scales. The outcome of the project was beyond our expectation.”

Mr Donal O’Sullivan, Managing Director, Sherkin Technologies UK Ltd. Commented: “Plastic packaging plays an important role in the reduction of food waste. Biodegradable food packaging usage has great potential to meet local and global targets for the use of sustainable packaging. The recent work undertaken by the IINM, and their industrial partners is an important step in demonstrating the potential for Low Energy Electron Beam as a platform technology which can be deployed to improve and optimise barrier properties in a new generation of biodegradable films.”

Read more about WMG’s Nanocomposites research here: Nanocomposites (warwick.ac.uk)

Smart dielectric elastomers for self-healing soft robots

- Soft robots must be made of a flexible and damage-tolerant material to avoid tearing

- Materials that can self-heal damages are therefore more desirable for soft robots

- A self-sensing and self-healing device that mimics a leaf’s motion has been made by researchers at WMG, University of Warwick – potential for soft robots

Robots that resemble organs are known as soft robots, and in order for them to function they must be made of a flexible material, however a material that can also heal itself would be a bonus if wear and tear was to occur. Researchers from WMG, University of Warwick have designed a self-healing polymers for such devices.

Soft robots, that resemble organs for example, need to be made with highly deformable materials that are capable of changes in shape to allow conformable physical contact for controlled manipulation on order to decrease the chances of mechanical damage – such as tears and punctures.

This had led to a wide interest into the development of self-healing materials and actuators, in particular, the integration of self-healing polymers for bioinspired soft self-healing devices, which are lightweight, low cost and easily processed.

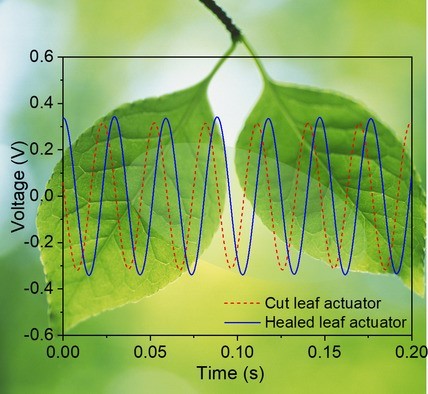

As an invited Communication by the journal Advanced Intelligent Systems, the work on ‘Piezoelectric-driven self-sensing leaf-mimic actuator enabled by integration of a self-healing dielectric elastomer and a piezoelectric composite’, was published on 22 March, 2021, led by the researchers from WMG, University of Warwick have designed a novel self-healing leaf-motion mimic material.

As an invited Communication by the journal Advanced Intelligent Systems, the work on ‘Piezoelectric-driven self-sensing leaf-mimic actuator enabled by integration of a self-healing dielectric elastomer and a piezoelectric composite’, was published on 22 March, 2021, led by the researchers from WMG, University of Warwick have designed a novel self-healing leaf-motion mimic material.

The material is made of an integrated thermoplastic methyl thioglycolate–modified styrene–butadiene–styrene elastomer (MGSBS) and piezoelectric macro fiber composite (MFC) for self-sensing applications.

The leaf-motion mimic actuator provides built-in dynamic sensing and self-healing capabilities to heal macroscale cutting damages with a room-temperature healing capacity and an intrinsic high bandwidth up to 10 kHz.

A prototype of the piezoelectric driven self-healing leaf was cut, and left for 24 hours at room temperature, in that time it had healed itself, after 48 hours it was almost untraceable where the cut had been made.

Dr Chaoying Wan, from WMG, University of Warwick comments:

“We have demonstrated the feasibility and potential of the new actuator applied to complex soft autonomous systems. This new material could fill a gap in the robotics-market, as the self-healing soft actuators can sense and repair themselves, creating new damage resistance in soft robotics.

“An example of where they could be used could be in a factory or hospital, they may get damaged from general wear and tear but can heal themselves and therefore do not need to come off duty to be fixed, therefore saving time and resources.”

ENDS

27 APRIL 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/april_2021/chaotying_image.jpg

Caption: Time and Voltage of a cut-leaf actuator and healed leaf actuator

Credit: WMG, University of Warwick

Paper available to view at: https://onlinelibrary.wiley.com/doi/10.1002/aisy.202000248

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwickac.uk

Solid-state batteries could be made more cleanly by scaling-up flash sintering

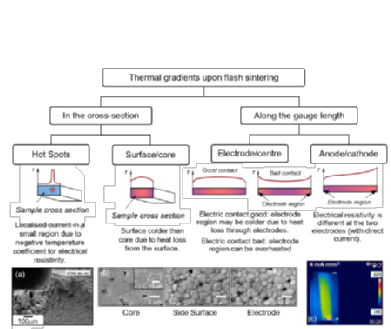

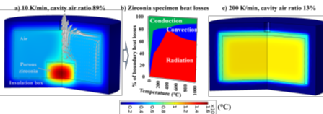

· Flash sintering is a ceramic processing technique which uses electric current to intensively heat the ceramic sample internally rather than using only external furnace heating. The process can lower ceramic processing temperatures and durations significantly, enabling ceramics to be co-processed with metals or other materials, and reducing energy use.

· However, the process can result in low quality ceramics due to weaknesses caused by inhomogeneities in the microstructure.

· The origins of these inhomogeneities caused by thermal gradients in the material during flash sintering have been studied by researchers based at WMG, University of Warwick and academic and industrial collaborators, and routes to mitigate the effects of these gradients are outlined.

· Adopting these modified flash sintering routes will enable the wider use of flash sintering in ceramic processing, enabling lower energy production of many useful ceramic products including solid-state batteries.

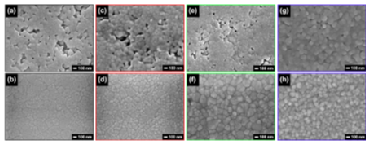

Densifying ceramics using flash sintering reduces energy use and may be used to improve the viability of manufacturing complex ceramic structures such as those required for solid state batteries by lowering the temperatures and shortening the duration of the heat treatment.

Working in collaboration with academic and industrial partners, researchers from WMG, University of Warwick have published a review of the state of the art of flash sintering focusing on the formation of inhomogeneous regions within the ceramics which currently limit the scale-up potential of flash sintering. The review finds that thermal gradients are responsible for microstructural inhomogeneities and suggests of routes to eliminate or reduce these effects.

of flash sintering focusing on the formation of inhomogeneous regions within the ceramics which currently limit the scale-up potential of flash sintering. The review finds that thermal gradients are responsible for microstructural inhomogeneities and suggests of routes to eliminate or reduce these effects.

The reduction of energy use in the ceramic manufacturing industry is a key step in meeting global emissions reduction targets, as conventional processes require long firing treatments at very high temperatures. Several low-energy processes have been developed over the past decade, with flash sintering emerging as a particularly promising route for densification of materials for use in applications including solid state batteries, thermal barrier coatings, and ceramic joints.

In the paper, ‘Promoting microstructural homogeneity during flash sintering of ceramics through thermal management’ published as part of a special issue of the MRS Bulletin, Gareth Jones and Dr Claire Dancer from WMG, University of Warwick worked with collaborators from the University of Trento, Wuhan University of Technology, Normandie Université, and Lucideon Ltd to review the origins of microstructural variations in different regions of ceramic materials undergoing flash sintering.

Differences in microstructural development originate from thermal gradients within the material during processing, and these can be reduced by careful thermal management during the flash sintering process. These include:

Differences in microstructural development originate from thermal gradients within the material during processing, and these can be reduced by careful thermal management during the flash sintering process. These include:

· Altering the method for applying electrodes

· Improving thermal homogeneity through insulation

· Tailoring the frequency of the AC current

· Developing contactless methods for applying the electric current - which are currently limited to consolidation of thermal barrier coatings.

The findings of this review provide a roadmap for further research on thermal management in flash sintering, which will accelerate the development of the process for industrial implementation.

Dr Claire Dancer, leader of the Ceramics Group within the Materials and Sustainability Directorate at WMG, University of Warwick comments:

“Lowering ceramic processing temperatures by using techniques such as flash sintering is an essential step for manufacturing complex multi-material structures such as those needed for solid-state batteries, and for lowering overall energy use in the ceramic industry.

“However, the process must produce robust homogenous ceramic materials to be of widespread use. Our paper explains why flash sintering can result in inhomogeneous properties in ceramics and suggests a number of routes to mitigate these effects.”

ENDS

9 MARCH 2021

NOTES TO EDITORS

The work has been funded by an EPSRC New Investigator Award, a PhD studentship from ERDF and Lucideon, the Royal Society, and the High Value Manufacturing Catapult.

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/march_2021/figure1.png

Caption: Causes and Effects of thermal and microstructural gradients in flash sintered ceramics.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/march_2021/figure2.png

Caption: Microstructural development changes with different sintering approaches. Flash sintering produces fine microstructures with very high density with lower energy use than conventional approaches.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/march_2021/figure3_png.png

Caption: Simulation of heat distribution during flash sintering.

Credit: WMG, University of Warwick

Paper available to view at: https://link.springer.com/article/10.1557/s43577-020-00010-2

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Fellowship funding for WMG researcher

WMG Research Fellow, Dr David Fengwei Xie has been awarded a prestigious five-year EPSRC Early Career Fellowship.

WMG Research Fellow, Dr David Fengwei Xie has been awarded a prestigious five-year EPSRC Early Career Fellowship.

Based in the International Institute for Nanocomposites Manufacturing (IINM), Dr Fengwei Xie has been working on sustainable polymer materials and composites for tackling the current issues around petro-derived plastics, recycling, and single-use plastics. His fellowship will allow him to further explore in this highly important area and to develop functional, biopolymer-based composite materials with tailored structures and properties for demanding applications.

The fellowship will provide his projects with sufficient funding and a dedicated team that will engage with the public, industry and policymakers.

An EPSRC Fellowship is designed to provide the recipient with the necessary support to establish or further develop themselves as a leader of the future. The award enables the recipient to devote their time to delivering their proposed research vision.

Dr Fengwei Xie explained: “The support provided by the EPSRC will allow me to develop my technical and transferrable skills to the greatest extent, become an independent and leading academic in advanced biopolymer materials engineering, and establish and grow my own group – fulfilling my career ambition.

“I am extremely excited to be awarded this fellowship as it will allow me to continue working on ‘green’ polymer composites for people’s welfare and a sustainable future.”

Read more about WMG’s Nanocomposites research here.

WMG and Senergy Innovations Ltd launch Graphene Enabled All Polymer Solar Thermal Cell

Solar thermal cells continue to attract much interest as they have massive potential to heat water in a cost-effective and sustainable process. To date, the efficiency of these cells has been limited as the polymers used in their manufacture are poor thermal conductors.

Solar thermal cells continue to attract much interest as they have massive potential to heat water in a cost-effective and sustainable process. To date, the efficiency of these cells has been limited as the polymers used in their manufacture are poor thermal conductors.

However, thanks to funding from BEIS (Department for Business, Energy & Industrial Strategy) a team of researchers led by Professor Tony McNally, from WMG, at the University of Warwick in partnership with Senergy Innovations Ltd have developed the first nanomaterial enabled all polymer solar thermal cell.

The thermal properties of the polymers employed are modified such that heat from sunlight can be transferred with high efficiency to heat water in a cheap and sustainable manner. The modular design of the cells allows for the rapid construction of a solar thermal cell array on both domestic and industry roofing.

The team are now working with a consortium of industry partners focused on manufacturing the solar thermal cells in high volumes.

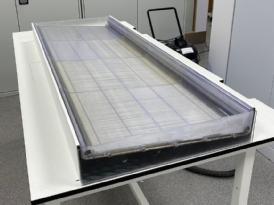

Dr Greg Gibbons, at WMG, and his team have also produced the first prototype (1:1 scale) of the solar thermal cell fully manufactured by 3D printing. This activity has been transformative in guiding the design and critical aspects of the manufacture of the solar thermal cells.

Professor Tony McNally, Director of the International Institute for Nanocomposite Manufacturing (IINM), at WMG, University of Warwick comments:

“It is really pleasing to see several years of research activity and the understanding gained being translated in to a real world application. Our fundamental  work on the thermal conductivity of 1D and 2D materials, including graphene, and composites of these materials with polymers could revolutionise the supply of affordable, clean and sustainable energy.”

work on the thermal conductivity of 1D and 2D materials, including graphene, and composites of these materials with polymers could revolutionise the supply of affordable, clean and sustainable energy.”

Christine Boyle, CEO, Senergy Innovations Ltd. adds:

“Switching to advanced polymer materials meant a more efficient manufacturing process and more flexible product design. This resulted in the breakthrough of the low cost, low carbon, lightweight smart Senergy panels. Our job now is to ensure that Senergy solar panels become a key part of the smarter built environment and make renewable heating and cooling systems affordable and accessible for everyone.”

ENDS

15 OCTOBER 2020

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/tony_m_solar_cell_testing.jpg

Caption: The solar cell as it went in for testing

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/christine_boyle.jpg

Caption: Christine Boyle, CEO of Senergy Ltd with the Solar Panel

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG PhD student attends prestigious Global Young Scientists Summit

WMG PhD student Chris Ellingford has been selected to attend the 8th Global Young Scientists Summit (GYSS) in Singapore from 14 to 17 January 2020.

WMG PhD student Chris Ellingford has been selected to attend the 8th Global Young Scientists Summit (GYSS) in Singapore from 14 to 17 January 2020.

Chris was one of only 300 participants, from across the world, and one of only five from the University of Warwick invited to attend.

GYSS gathers young researchers and scientists from across the world to encourage them to pursue their scientific ambitions. They have the chance to network with peers, as well as distinguished scientists and researchers.

The theme for this year’s event is "Advancing Science, Creating Technologies for a Better World,” with an impressive line-up of speakers including recipients of the Nobel Prize, Fields Medal, Millennium Technology Prize and Turing Award.

At GYSS Chris, as one of only 100 participants selected, will present at the poster session, and take part in lectures and panel discussions, and have the opportunity to interact with speakers in informal small group sessions. Outside of the Summit, Chris will also have the chance to visit local universities and research centres to learn more about Singapore’s research and innovation ecosystem.

Chris is currently in the 4th year of his Research Degree at WMG. He is based within the Nanocomposites team investigating "Self-healing Elastomeric Nanocomposites for Actuation and Energy Harvesting."