QCM cleaning guidelines

Before use:

Check the system visually and make sure all the screws are tightened firmly and the sensor is in position correctly.

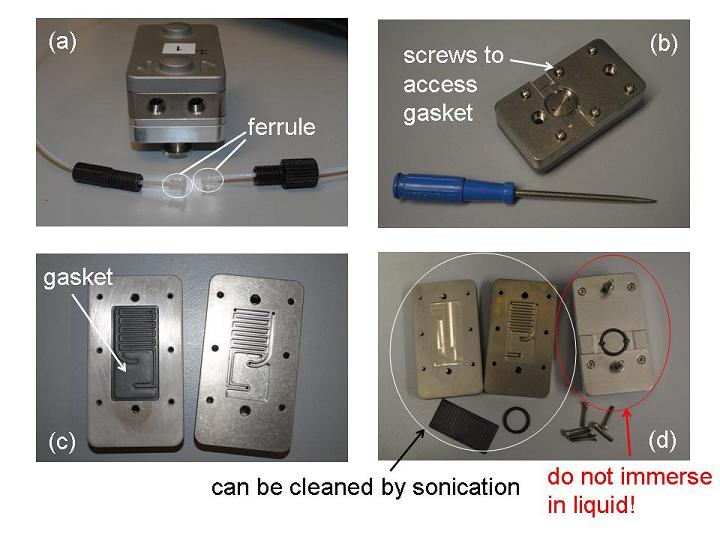

There should be one ferrule (a) at the end of each piece of tubing, check that it has not come off and become stuck in the hole.

If one of the cells is blocked, check each piece of tubing and the cell separately by syringing through deionised water to find the blockage.

If the flow cell itself is blocked, it can be opened up by opening the cell (as to insert a sensor) and removing the six screws (b). Check there is no debris in the channels (c).

The gasket, o-ring and metal parts of the flow cell shown in (d) can be cleaned by sonication; the part of the flow cell which contains the electrical contacts should never be immersed in liquid.

Standard cleaning procedure after use:

Run SDS solution (sodium dodecyl sulfate, ~0.5 % (aq)) (approximately 15 minutes)

followed by water (approximately 15 minutes)

followed by air (approximately 5 minutes)

at maximum pump speed.

This page is no longer in use.