Case Study: Wastewater derived ammonia: contaminant to carbon free transportation fuel

This is the first project to demonstrate the intrinsic value of ammonia in wastewater as a transportation fuel through practically realising recovery of a purified ammonia product and applying it for direct electrical energy generation. The study therefore establishes the feasibility for production of a new sustainable transportation fuel from wastewater and provides fundamental understanding of a new technological innovation to unlock the available energetic potential of ammonia in wastewater.

Links

"Wastewater derived ammonia: contaminant to carbon free transportation fuel" Full reportLink opens in a new window

Executive Summary

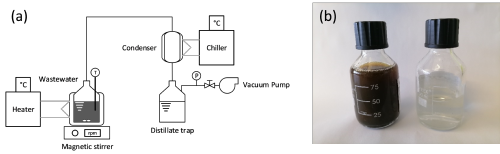

This project has demonstrated the recovery of a purified aqueous ammonia fuel from wastewater and its utilisation for electrical energy generation in a direct ammonia fuel cell (DAFC) suitable for transportation applications. This has been the first practical demonstration of this process with the fuel cell exhibiting an open circuit voltage (OCV) of ~0.2V and power density ~0.005 mW cm-2 when fed with ammonia distillate from real wastewater. Practical demonstration of this linkage between vacuum distillation and a direct ammonia fuel cell has identified key characteristics of the recovered ammonia fuel to further optimise for improved electrical energy generation. This includes increasing concentration of the recovered distillate, with fuel cell power density improving almost tenfold through an increase in ammonia concentration to 5M. Additionally, trace organic contaminants contributed to a reduction in solution pH and adsorbed to the anion exchange membrane of the fuel cell, reducing power output by around half, indicating that upstream intervention is required for their removal (e.g. granular activated carbon) to achieve an improved process energy efficiency. The project has however established the feasibility of producing a new sustainable transport fuel from wastewater and provides a fundamental understanding to build upon for process scale up.

(a) Schematic of the experimental set-up of the vacuum distillation system used to recover ammonia distillate and (b) image of the wastewater and the recovered distillate.

Key Findings

1) Electrical energy generation has been demonstrated from a concentrated ammonia product derived from real wastewater which could be applied as transportation fuel. Initial studies have produced a distillate with ammonia concentration of ~1M producing an OCV ~0.2V and power density of ~0.005 mW cm-2 when applied in a DAFC.

2) The impact of organic contaminants reduced the pH, OCV and power density of the ammonia distillate compared to a synthetic ammonia solution of equivalent concentration. Increasing purity and concentration through simple engineered approaches (e.g. fixed carbon beds) could enhance energy generation, conversion efficiency and overall ammonia abatement of the DAFC.

Project Team

|

Chris Davey (PI) Chris’ current research activities include investigating a number of membrane-based processes for: water recovery from concentrated blackwater, resource recovery and electrochemical energy generation. His research interest lies at the water-energy nexus aiming to develop new technologies and processes to achieve decarbonisation of energy systems and energy positive water treatment. |

|

|||

|

Ewan McAdam (Co-I) Prof. McAdam’s research focusses on the development of hybrid technologies for the water sector that enable selective separations, chemical transformations and gas-liquid mass transfer to realise opportunities in process intensification, energy production or resource recovery. |

|

|||

|

Ben Luqmani Chemical Engineer with a first-class degree from the University of Bath. Ben is leading the design build and operation of a laboratory scale thermal ammonia recovery unit used to produce NH3 products from wastewater. Nigel Janes Mr Janes’ expertise includes overseeing the installation and commissioning of novel water treatment technologies for industrial scale testing. Rob Evans Over 15 years working in IP management and commercialisation. He leads on management of the patent portfolio and IP exploitation for Cranfield University. He has successfully commercialised over 50 technologies, through eight spin out companies and over 40 licence agreements. |

|

|||

Industry PartnersSevern Trent Water Mr Peter Vale, Innovation Lead Sever Northumbrian Water Mr Andrew Moore, Commercial manager Anglian Water |