Case Study: Identifying the Potential for Zero Waste Decommissioning of Commercial Aircraft

This is the first project to focus on the challenges surrounding the post-COVID aviation decommissioning landscape. With sustainable aviation in the spotlight and the need to consider more sustainable end-of-life options for aircraft the project is quite timely. Only by looking at novel approaches to the actual decommissioning process and the valorisation of waste can we start viewing the sector as being green.

Links

"Identifying the Potential for Zero Waste Decommissioning of Commercial Aircraft" Full report

Executive Summary

COVID-19 has had a profound impact on the aviation sector with airlines collapsing and several thousand aircraft being prematurely retired. With the pressure towards adopting sustainable practices and an over availability of aircraft the impact on the decommissioning sector cannot be understated.

This project focused on the UK aircraft decommissioning sector identifying key stakeholders, current practices, supply chain and new opportunities. While the role of the decommissioner does not yield great wealth there are opportunities to incorporate new technologies and move away from the current shredding process used for reducing the fuselage and interiors into waste for further reprocessing.

Repurposing opportunities were identified through engagement with various organisations including office work pods, textile reuse and the downcycling of composite material.

Some of the lessons learnt and opportunities identified have potential cross-over to other modes of transportation which are reaching their end-of-life and disposal may no longer be a viable or attractive option.

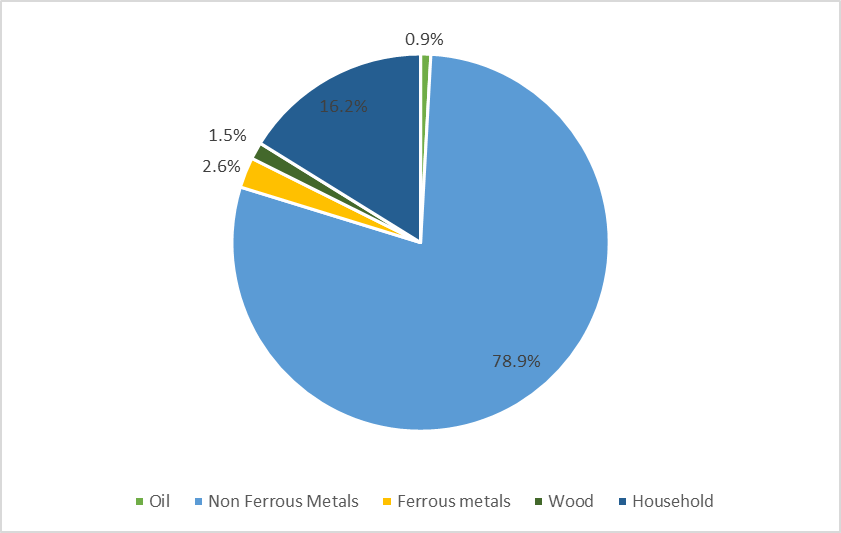

Waste by Material Type

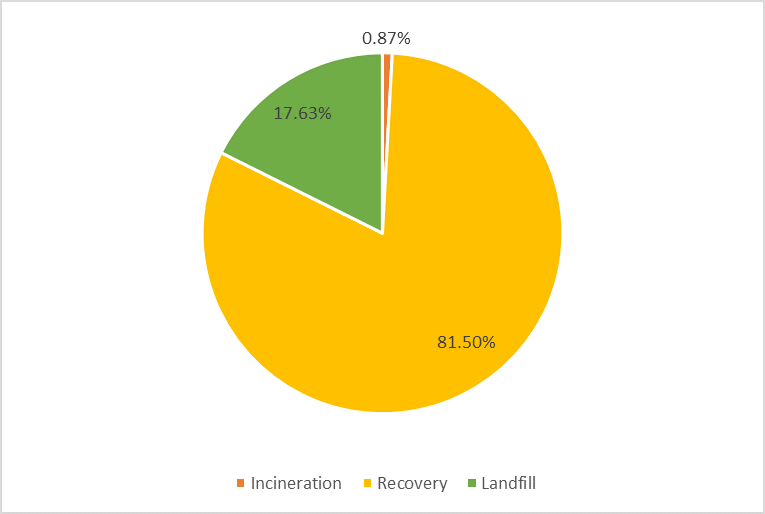

Waste by Fate

Key Findings

1) The current UK aircraft decommissioning sector operates on relatively slim profit margins with income derived from labour costs associated with removal of key assets from the aircraft and the potential value for scrap materials.

2) There is potential to decommission aircraft in a more sustainable manner, but this is currently thwarted by high labour costs and no economic reward. Going forward this is likely to change due to societal, environmental, and legislative drivers which push for greener alternatives. The application of automation and new technology will be a gamechanger in increasing productivity and lowering costs.

Project Team