Life Extension of Materials in Transport

The objectives of this project are as follows,

• List potential techniques that can be used regularly to extend the fatigue life of metallic materials,

• Understand the compliance regarding reliability and airworthiness certifications that limit the extension of the fatigue life of airframes components,

• Rank most appropriate techniques and materials with their circularity impact.

• Make recommendations for further research.

Links

"Rejuvenating Materials for Supporting Circular Economy" Full reportLink opens in a new window

Executive Summary

Circular materials are at the core of sustainable transport in a green economy. Improvements to material productivity and reusability can help improve circularity by reducing extraction and enabling efficient fully recyclable vehicles. The quest for such circular materials is often framed as a choice among reuse, renew or recycle materials, which omits maintenance. Indeed, technology adoption for preventive materials therapies are very low and underexplored.

Although the discovery of novel materials can accelerate the transition of a linear into a circular economy, some transport industries are intrinsically reluctant changes. These industries must assure passengers safety and they often rely on years of experience for assuring fitness for purpose. For example, the aerospace industry is typically change-averse and would normally require long terms to adopt novel sustainable materials. Thus, rather than shifting into novel materials, these industries would benefit from applying accepted repairing techniques to heal preventively the potential damage on components.

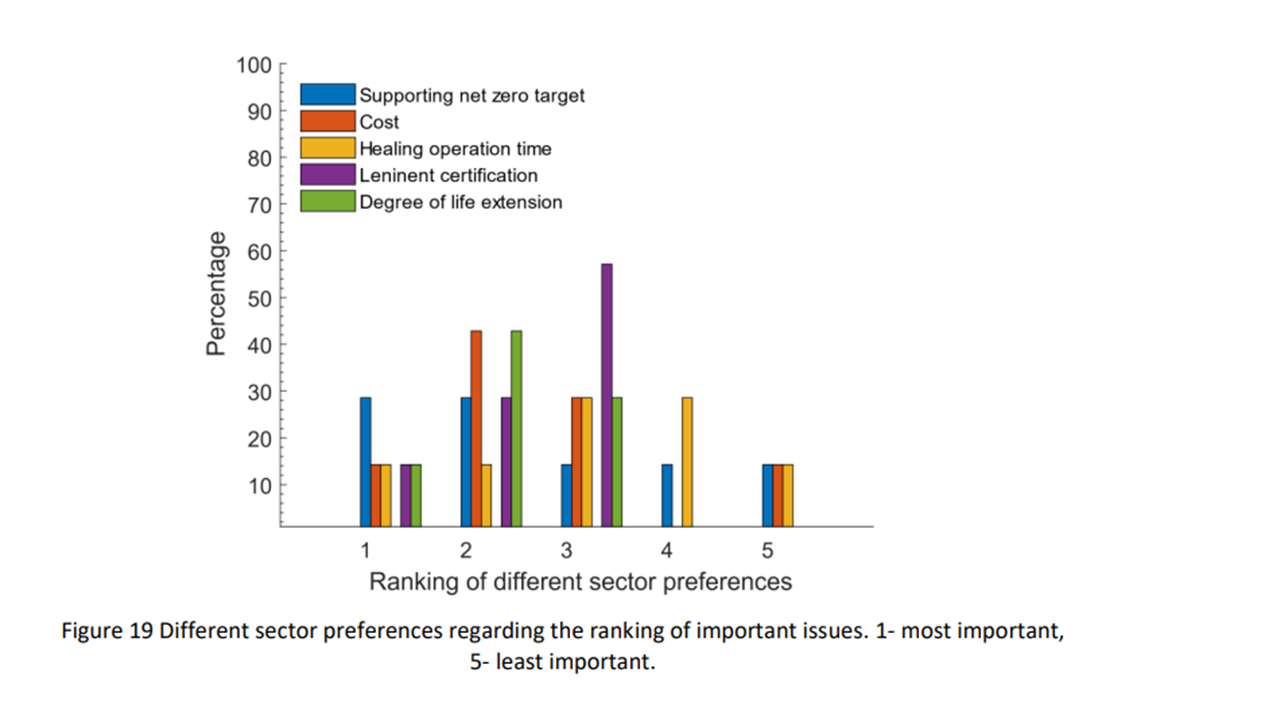

This work explores the potential of novel “preventive maintenance of materials” and rank various techniques that can be used to extend the structural life of metallic components. We consider scientific data as well as industrial feedback to assess the ecofootprint and feasibility of techniques. The results identify those techniques can have the most circularity impact on transport industry. The findings also support future research in sustainable maintenance techniques.

Key Findings

In terms of circularity, our analysis suggests that mechanical techniques tend to have marginally better material circularity indicators (MCIs), but all technologies have a similar level of MCIs. Hence, material and energy consumptions are the primary footprint indicators.

The feedback from our industrial partners suggests that many of these techniques are being currently used to repair existing damage rather than for preventive maintenance. In terms of implementation of techniques, most participants suggested that mechanical and coating are easy to implement compared to thermal. Similarly, the majority reported that mechanical is relatively cheaper than other techniques while coatings have the advantage that it can be done on assembled parts on site.

Project Team

Dr. Farhan Ashraf

Dr. Arijit Lodh

Dr. Gustavo M. Castelluccio

School of Aerospace, Transport and Manufacturing

Cranfield University