Recovery of Transport Battery Metals for a Circular Value Chain

This project is the first demonstration of the ion transport of lithium ions through an ion selective membrane for the purpose of purification.

Links

"Recovery of Transport Battery Metals for a Circular Value Chain" Full reportLink opens in a new window

Executive Summary

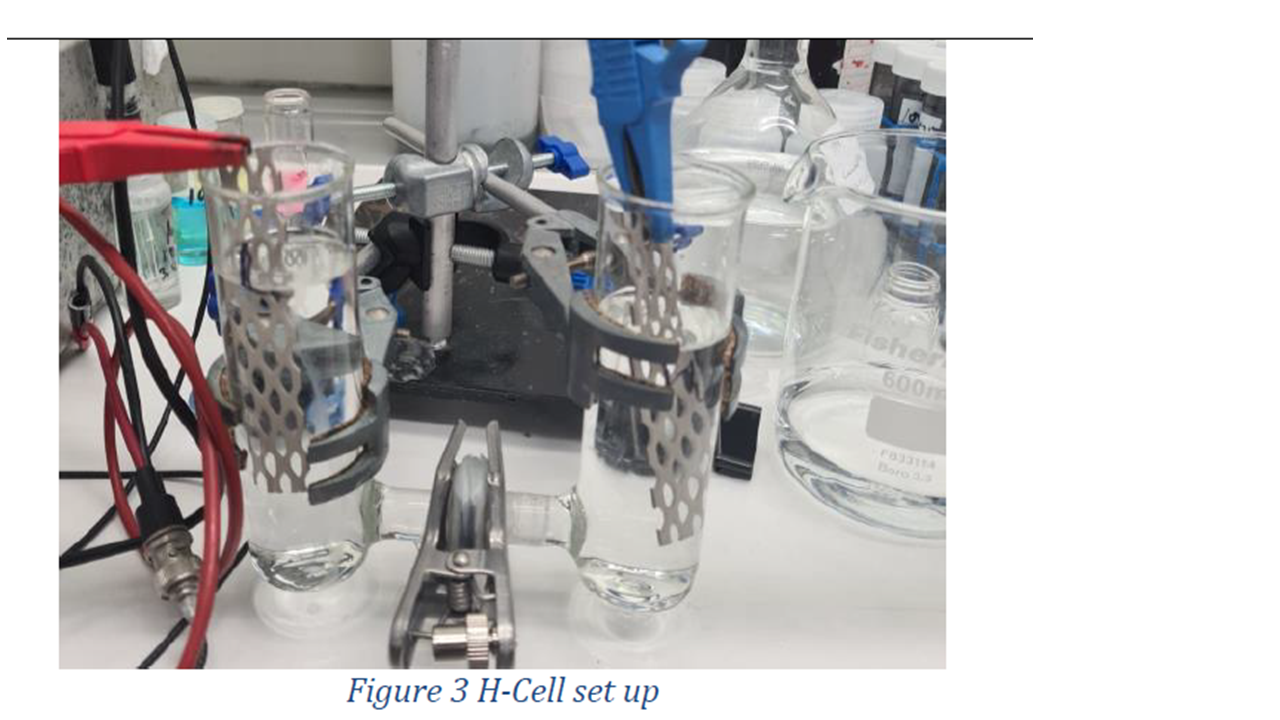

This research has demonstrated that membranes for ion transport have the potential to recover lithium-ion from waste recycling solutions to prepare purified LiOH, which can be fed back into lithium-ion battery production. Proprietary Nafion membranes have been successfully prepared using different methods to improve lithium-ion conductivity, suitable for both solid polymer electrolytes and lithium-ion recovery. H-cell and flow cell were designed and set up for testing of membranes. During testing of the lithium-ion recovery process, ion-transport and pH changes occurred in the absence of an applied cell voltage which suggests the important consideration of ion-selectivity. Commercial Fumatech membranes were also tested in this discovery study, which shows early stage promises for future research into the recovery of purified LiOH battery precursor material.

Key Findings

1) Lithiation of Nafion film can increase lithium-ion conductivity of the membrane allowing for greater lithium-ion transport. However, lithium ions could not be selectively transported with the application of a potential at the electrodes, evidence from the H-Cell investigation suggests that the lithium ions are able to pass through the membrane without the application of any potential and so these membranes would not be selective enough for purification.

2) Commercial cation exchange membranes were able to transfer Lithium ions from a 1M LiOH solution to a water solution with the application of a potential. The membrane could be used in a larger scale flow cell to achieve comparable results, however the rate of lithium-ion transfer remained low and so further work to increase the rate of ion transport is required.

Project Team

Lauren Cooper MChem. 2 years’ experience working at WMG on projects related to energy innovation, with 1 year in the battery recycling team working on new methods for recycling lithium ion batteries.

Anwar Sattar, PhD, Meng. Leads battery recycling activities at WMG. Has been working on lithium ion battery recycling since 2016

John Low, PhD, BEng. Focuses on the application of electrochemical engineering for lithium and lithium-ion batteries, taking materials science into technology manufacturing and recycling.