Electrospinning

Electrospinning is a process used to manufacture nano-sized fibers from various materials, such as polymers.Various drugs can also be used in conjunction with polymer materials in order to encapsulate the drugs within the fibers.Diameter control and fiber layering are two other structural characteristics of the electrospun fibers that can be tailored using electrospinning.

How does it work?

How does it work?

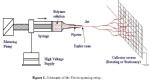

A polymer solution is injected at a constant feed rate though a nozzle or needle which is charged to a high voltage, typically 10 to 30 kV. The applied voltage induces a charge on the surface of the liquid droplet and when this is sufficiently high, the hemispherical surface of the fluid elongates and a Taylor cone is established. On increasing the applied voltage further, a charged liquid jet is ejected from the Taylor cone and attracted to the earthed collector, which is positioned at a fixed distance from the needle. During this process the solvent evaporates from the polymer solution, leaving dry polymer fibres on the collector.

Applications:

Nanoscale texturing, Nanofibre scaffolds for 3D cell culture, drug delivery, stem cell transportation, lithium ion battery seperators, ultracapacitors, hydrogen fuel cells, filtration, specialist, clothing

Sample handling requirements:

Appropriate polymer solution or ‘melt’ of fibre material.

Complementary techniques:

Pulsed Laser Deposition, Rheology, Photolithography

Warwick capability:

Contact:

Claire Gerard: c dot gerard at warwick dot ac dot uk / 07385 145064

Typical results format, and sample:

Status |

Availability |

| Warwick collect/analyse data | |

| Warwick collect data | |

|

Available to user with expertise/ contribution |

|

Spare capacity for collaborative research |

BOOK NOW |