X-Ray Photoelectron Spectroscopy (XPS)

X-ray photoelectron spectroscopy (XPS) is an analysis technique used to obtain chemical information about the surfaces of solid materials. Both elemental composition and the chemical state of surface constituents can be determined by XPS. Conducting, semi-conducting and even some insulating samples can be analysed in-situ across surface areas from a few microns to a few millimetres across.

Applications:

Typical measurements include chemical composition, oxidation state analysis, identification of species, surface reactions, imaging of patterned surfaces and deposits.

Typical samples include, but are not limited to, nanoparticles, graphene, surface coatings, photovoltaics, semiconductors, plastics, lithium batteries, drug delivery, resins, sugars, steels and carbide materials.

How does it work?

The sample is placed in an ultrahigh vacuum environment and exposed to a monochromatic x-ray source. The incident x-rays cause the ejection of both valence and core-level electrons from atoms close to the surface of the material. The energy of a photoemitted core electron is a function of its binding energy and is characteristic of the element from which it was emitted.

Analysis of the energy spectra of the emitted photoelectrons is the primary method of determining the surface composition. The surface sensitivity of the XPS techniques derives from the escape depth of the excited electrons which typically come from the uppermost 2-5 nm. By counting the number of photoelectrons as a function of their energy, a spectrum representing the surface composition is obtained. The energy corresponding to each peak is characteristic of an element and its bonding environment.

Sample handling requirements:

Sample size cannot exceed 15 mm in any lateral direction and can be powders. Height should not exceed 3 - 4 mm. Sample must be compatible with an ultra-high vacuum environment (<10-9 mbar). Please feel free to ask if you are unsure.

Complementary techniques:

UPS, TEM, XRD, SEM, EDX, AFM, PLD, STM

Warwick Capability:

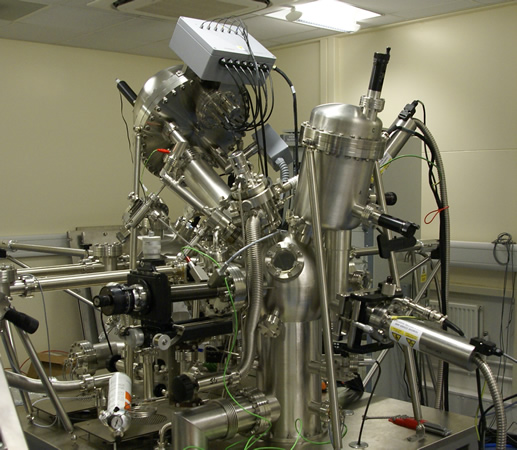

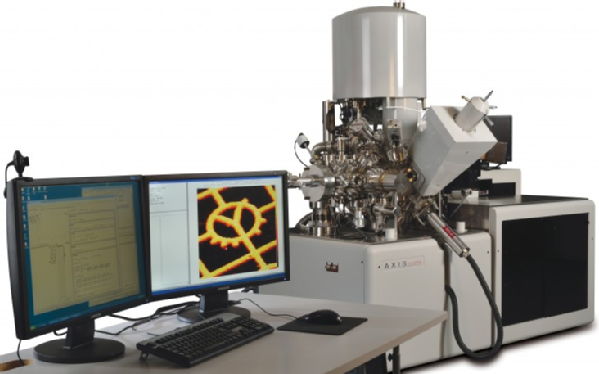

Members of the Surface & Interface Group have a wealth of experience in XPS analysis and XPS data handling. Two main systems are available, a Kratos Axis Ultra DLD with imaging and automated measurements, plus an Omicron system for high resolution XPS and UPS.

Contact:

Claire Gerard: / 07385 145064

Additional Contacts:

Dr Ian Hancox, / 024 76 150 380

Dr Marc Walker, / 024 76 151 776