Clean Transport

Global emissions from road transport are rising faster than in any other sector. Road transport accounts for over 10% of global emissions, as well as causing high levels of local air pollution.

The growth of the global market in zero emission vehicles (ZEVs) is outpacing expectations, and some estimates project that they will make up over 50% of all new car sales by 2040. However, to meet the goals of the Paris Agreement, 100% of new car sales need to be zero emission by then. In other words, we need to double the pace of the global transition to zero emission vehicles.

Advanced power electronics for electric vehicles, School of Engineering

With a 4-year Royal Society Industry Fellowship, Professor Layi Alatise is researching the implementation of advanced power electronics for electric vehicles. One of the main routes to industrial de-carbonization is the electrification of transportation. Power electronics is key to electrifying transportation since it is the technology that enables energy stored in the battery to converted into energy for the electrical machine driving the vehicle. It also enables the conversion of 3-phase AC power from the electrical grid to DC power stored in the vehicle battery. As vehicle sizes and battery capacities increase, so must the power rating of the power electronic converters that enable traction and vehicle charging. This project is oriented towards developing a new generation of medium voltage power electronic devices and gate drivers for traction inverters. Professor Alatise is working with Bourns Incorporated UK to explore UK manufactured IGBTs.

New insight into how lithium-rich cathode materials for high energy EV batteries store charge at high voltages, WMG

Electric vehicles will one day dominate UK roads and are critical for eliminating CO2 emissions, but a major issue car manufacturers face is how to make an affordable long-lasting energy-dense battery that can be charged quickly and efficiently. There is therefore a race to make EV batteries with an energy storage target of 500 Wh/Kg, but these targets are not possible without changing to new cathode materials.

Electric vehicles will one day dominate UK roads and are critical for eliminating CO2 emissions, but a major issue car manufacturers face is how to make an affordable long-lasting energy-dense battery that can be charged quickly and efficiently. There is therefore a race to make EV batteries with an energy storage target of 500 Wh/Kg, but these targets are not possible without changing to new cathode materials.

Although progress has continued over the last 10 years to push the performance of state-of-the-art nickel-rich cathodes for EV, the material is unable to provide the energy density needed. To increase the capacity more lithium needs to be used, which means going beyond the ability of nickel to store electron charge.

Lithium-excess magnesium-rich cathodes offer sufficient energy density but to reach ultimately reach energy storage targets of 500Wh/Kg we need to understand how the electron charge is stored in the material. Simply put, is the electron charge stored on the magnesium or oxygen sites.

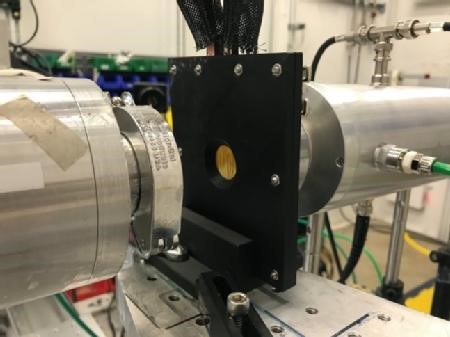

Researchers performed operando x-ray studies to precisely quantify magnesium and oxygen species at high voltages. They demonstrated how x-ray beams could irreversibly drive highly oxidized magnesium (Mn7+) to trapped O2 gas irreversibly in other materials.

Professor Louis Piper, from WMG, University of Warwick explains:

“We have ultimately resolved that oxygen rather than metal redox is driving the higher capacity, which means we can now design better strategies to improve cycling and performance for this class of materials.”

Please follow this link for more information.

Is a new UK-wide transport strategy the answer to fast recovery?, Department of Economics

The government’s pan-UK approach to transport, laid out in its recent report on union connectivity, is refreshing. But, Marta Santamaria argues, the report overlooks some important considerations to enable resilient and flexible infrastructure for the future.

Prime Minister Boris Johnson proposed a significant investment in pan-UK transport links to lead the way to recovery and growth. For this, he commissioned Sir Peter Hendy, Chairman of Network Rail, to review the problem of Union Connectivity. The interim report was released in March. It outlines what the UK transport network may look like in the next 20 years, after gathering evidence from a wide range of sources including governments, industry and the general public.

The central goals are to level up parts of the country that have been ‘left off the transport map’ and to improve connectivity across nations. The review considers the current weaknesses of transport by rail, road, air and sea. A few of the priorities are to strengthen the cross-border rail network further than HS2, to upgrade road connections across nations, especially between England and Scotland, and to reduce passenger duties on domestic flights.

The pan-UK approach of the review is refreshing. Domestic travel and transport are extremely important. Furthermore, given the geographic nature of the UK, upgrading links across nations also improves connections to the main international ports and airports, most of which are in England.

Unfortunately, the review overlooks some important issues.

1) No post-Brexit response: There are only two mentions of Brexit in the report (in the introduction). This is disappointing. My recent research with Jaume Ventura and Uğur Yeşilbayraktar has found that country borders in the EU reduce trade across regions by 80%, and we can expect this number to increase once tariffs or other non-tariff barriers are in place.

As the PM pointed out, ‘it’s currently quicker to get a train from Cardiff to Paris than from Cardiff to Edinburgh’. For the last 50 years, the UK’s infrastructure supported fast cross-continental trade and travel. If demand for travel and transport between the EU and the UK falls after Brexit, as expected, the infrastructure network will have to be reshaped or may become obsolete.

2) Lack of global vision: After Brexit, the UK will have to reach out for new partners and strong international corridors. As mentioned, domestic infrastructure also connects the country to international markets, firms and travellers. For instance, transport through UK ports is made up of 80% of international goods that, after entering the country, are distributed across the regions.[1] Who will be the UK’s new trade partners and how will goods and people travel? Investments should consider which traffic flows are likely to grow to make sure these port, airport and rail connections are upgraded.

3) Connectivity trumps environmental protection: The strong emphasis of the review on road and air shipping could leave train connectivity behind, potentially making the transport system less environmentally responsible, as already pointed out by transport experts.

The UK is living through unprecedented global and national changes. To the uncertainty left by Brexit we must add the global pandemic that has changed how we live, move and work. Some of these changes will stay after we have overcome the COVID-19 crisis. These extraordinary times require not only a forward-looking plan but also a resilient and flexible approach.

Transport infrastructure investments are costly and long-lasting. Decisions taken today will likely shape the regional distribution of activity in the UK for decades to come. History has shown us that infrastructure plans can be made irrelevant by unexpected shocks, as I show in a recent study on West Germany’s infrastructure response to the division of the country in 1949. In addition to the post-COVID economy and Brexit, the UK must respond to growing support for independence in Scotland and Northern Ireland. If more borders were to be established in the UK, failing to adapt the transport network to the new geography could entail large income costs.

It will be crucial that the cross-national plan takes a global view and considers connectivity to international markets so that the UK is not left isolated. Only a resilient and flexible transport system will remain valuable in the future, bringing about the desired recovery and growth for everyone.

Rapid grading for second-life automotive batteries, WMG

Batteries for electric vehicles (EVs) have a limited lifespan that varies depending on the format, chemistry and manufacturer. After this time, used automotive battery packs are sent back to the manufacturer for disposal and recycling. However, used Lithium-ion batteries often retain sufficient energy and power capability and might be suitable for ‘second-life’ applications, such as in renewables and static energy storage for domestic and industrial use. Manufacturers and reprocessing centres are under pressure to come up with robust grading processes to evaluate the economic liability of repurposing used Li-ion batteries, instead of disposal and recycling.

Following high sales of the Nissan LEAF since its European launch in 2010, Nissan have been keen to explore the second-life Lithium-ion battery market as an opportunity to create a new income stream and extend the battery value chain. Currently, the number of battery packs being returned to Nissan is very low, just tens per year. But from 2021, when the first vehicles start reaching the end of their life, those numbers will start ramping up. In anticipation of rising demand, and to evaluate the feasibility of this emerging business opportunity, the challenge was set to demonstrate 1MWh of energy storage at Nissan’s second-life facility in Sunderland by the end of 2019.

With no commercially available solution that met their requirements, Nissan partnered with WMG, AMETEK and Element Energy on the “UK Energy Storage Laboratory” project. Funded by the Department for Business, Energy and Industrial Strategy (BEIS).

Solution

To meet this industry challenge, WMG’s battery technology experts in the Energy Innovation Centre developed a safe, robust and fast methodology for grading used automotive Lithium-ion batteries, initially, at pack level. This methodology was successfully transferred to the Nissan second-life facility.

To meet this industry challenge, WMG’s battery technology experts in the Energy Innovation Centre developed a safe, robust and fast methodology for grading used automotive Lithium-ion batteries, initially, at pack level. This methodology was successfully transferred to the Nissan second-life facility.

Our team also trained and supported the Nissan Energy team in order to achieve the target of 1MWh of second-life energy storage.

Then, novel algorithms for grading battery modules were developed by WMG for use in specialist equipment supplied by AMETEK. This methodology reduced grading time from three hours to less than three minutes per module, with a proven accuracy of ±3.2% in State of Health (SOH).

Speaking about the approach we took to this project, Professor Dave Greenwood, Professor of Advanced Propulsion Systems at WMG, said: “To significantly increase the speed of module and pack testing meant moving away from traditional methods which simply charge and discharge the battery to see how much capacity it has left in it. In this project we brought testing techniques which are usually only used in laboratory environments into an industrial context. These much faster techniques measure the electrochemical performance of the materials in the pack, and our scientists were able to develop algorithms which accurately relate those characteristics to the remaining useful power and capacity of the used battery pack.”

Impact

The pack and module grading methodologies developed in this project have opened the door for Nissan to grasp the opportunities offered by second-life. It is the first time that the pack grading methodology has been demonstrated for volume manufacturing outside of the laboratory environment, showing its potential as an industrial system, able to scale up quickly to handle the volumes expected after 2021.

The process for grading battery modules is now being trialled at the second-life pilot facility. Nissan hopes to be able to re-use 90% of battery packs currently assembled in EVs in Europe by 2021, and has a plan to recover and recycle the remaining 10%.

| Researcher | Department |

Research Details |

|---|---|---|

|

School of Engineering |

With a 4-year Royal Society Industry Fellowship, Layi Alatise is researching on the implementation of advanced power electronics for electric vehicles. One of the main routes to industrial de-carbonization is the electrification of transportation. Power electronics is key to electrifying transportation since it is the technology that enables energy stored in the battery to converted into energy for the electrical machine driving the vehicle. It also enables the conversion of 3-phase AC power from the electrical grid to DC power stored in the vehicle battery. As vehicle sizes and battery capacities increase, so must the power rating of the power electronic converters that enable traction and vehicle charging. This project is oriented towards developing a new generation of medium voltage power electronic devices and gate drivers for traction inverters. Alatise is working with Bourns Incorporated UK to explore UK manufactured IGBTs. |