Ceramic industry should bring carbon reducing cold sintering process out of labs and into manufacturing says new research

A new techno-economic analysis, by a team led by a researcher from WMG at the University of Warwick, shows that the energy intensive ceramic industry would gain both financial and environmental benefits if it moved to free the cold sintering process from languishing in labs to actual use in manufacturing everything from high tech to domestic ceramics.

The new research has just been published in the Journal of the European Ceramic Society in a paper entitled “Decarbonising ceramic manufacturing: A techno-economic analysis of energy efficient sintering technologies in the functional materials sector”.

The cold sintering process (CSP) combines heat, pressure and the use of water to significantly reduce energy use as it lowers the temperatures required to produce ceramics to around 300 degrees centigrade. This is far less than other process such as: Conventional sintering, Laser sintering, Fast-firing sintering, Liquid-phase sintering, and Flash sintering which require far more energy and need to reach temperatures ranging from 1400 to 3000 degrees centigrade depending on the process and materials under consideration.

However the small scale of laboratory-based CSP (typically creating 5 grams of ceramic at a time under lab conditions) has meant that manufacturers have chosen to continue to rely on other significantly higher temperature methods that can either already produce larger amounts or can rapidly manufacture a series of small scale high tech ceramics. The University of Warwick led team believed that manufacturers had not developed anything like a full understanding of the potential financial and environmental benefits of using CSP in manufacturing – particularly as the start-up costs of CSP are much lower than other processes.

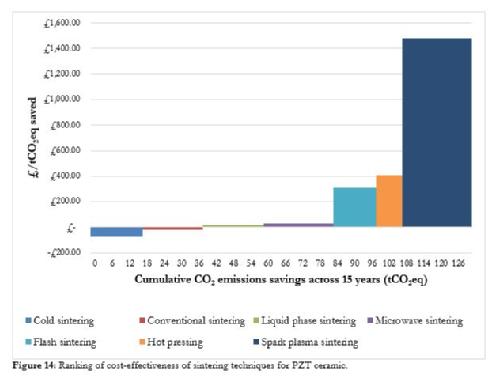

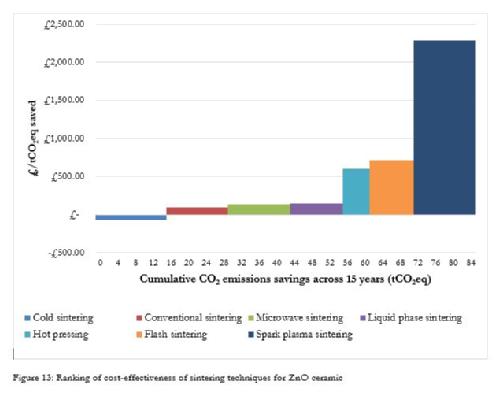

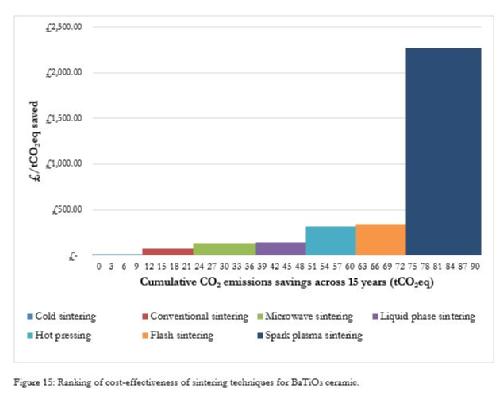

The researchers looked at scenarios for the processing of 3 separate functional oxides used to produce ceramics: ZnO, PZT and BaTiO3. They compared cold sintering (CSP) with a range of other sintering techniques and looked at its return on investment. They found that in all three cases, even after 15 years of use, the low set up costs of CSP made it the most economically attractive sintering option, with lower capital costs and best return on investment as well as considerable energy and emission savings.

The researchers do recognise that the transition from laboratory to industry of CSP will require hugely different facilities and instrumentation as well as relevant property/performance validation to realise its full potential but the potential benefits of doing so are significant .

Lead researcher on the paper Dr Taofeeq Ibn-Mohammed from WMG at the University of Warwick said:

“The rising cost of energy and concerns about the environmental impact of manufacturing processes have necessitated the need for more efficient and sustainable manufacturing. The ceramic industry is an energy intensive industrial sector and consequently the potential to improve energy efficiency is huge”

“Our research is the first comprehensive techno-economic analysis of a number of sintering techniques, comparing them with the recently developed cold sintering process (CSP). We find that there are clear financial and environmental benefits if the ceramics industry was to take the cold sintering process out of labs and into commercial manufacturing”.

Note for Editors: The full research team on the paper were: Dr Taofeeq Ibn-Mohammed from WMG at The University of Warwick; C.A. Randall and S. Berbano both from the Materials Research Institute, The Pennsylvania State University; , K.B. Mustapha from the University of Nottingham; , J. Guo from Xi’an Jiaotong University and Pennsylvania State University; J. Walker from Norwegian University of Science and Technology; S.C.L. Koh, D. Wang, D.C. Sinclair, and I.M. Reaney, all from The University of Sheffield

|

|

|

For interviews or a copy of the paper please contact:

Peter Dunn, Director of Press and Media Relations

University of Warwick

Tel office: 024 76523708 UK +44 (0)24 76523708 International

Mobile/Cell: 07767 655860 UK +44 (0)7767 655860 International

Email p.j.dunn@warwick.ac.uk Twitter @peterjdunn

Or

Alice Scott, Media Relations Manager, University of Warwick

Tel: 02476 574 255 UK or +44 (0)2476 574 255 international

or 07920 531 221 UK or +44 (0)7920 531 221 international

E-mail: alice.j.scott@warwick.ac.uk

Or

Lisa Harding, Head of Marketing and Communications, WMG,

University of Warwick Tel: 024 76 524721 or 07824 540845

email L.Barwick@warwick.ac.uk

PJD 21st October 2019