pBDD Disk Electrodes

pBDD Disk Electrode Fabrication

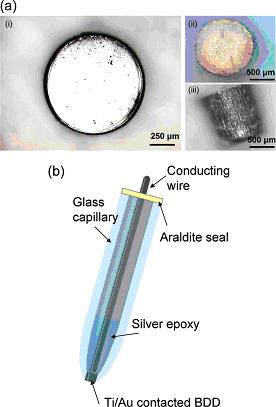

For easy use of pBDD in an recognisable electrode format we have constructed, robust and reliable pBDD macrodisk electrodes with well-defined dimensions. A laser micromachiner was used to cut 1 mm diameter pBDD columns from samples provided (Figure 1a). The pBDD columns were then acid cleaned and air dried. A reliable ohmic connection was made to the back of the pBDD by sputtering a layer of Ti followed by Au (Figure 1aii). The samples were then annealed forming a carbide-based tunnelling contact. The pBDD was sealed in a glass capillary so that only the top (disk) surface was exposed. Electrical contact was made to the pBDD/Au surface using silver epoxy and copper wire (Figure 1b).

Figure 1. (a) Optical microscope images of laser machined pBDD column polished surface: (i) top face in view; (ii) Ti/Au coated bottom surface in view,and (iii) side view. (b) Schematic of a pBDD disk electrode.

pBDD Disk Electrode Characterisation

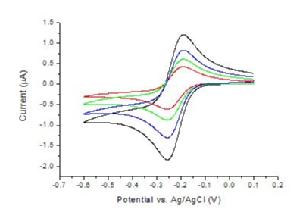

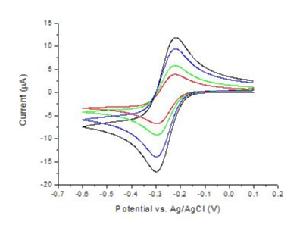

In order to verify the electrochemical behaviour of the fabricated pBDD disk electrodes, cyclic voltammograms for the reduction of Ru(NH3)63+ at concentrations of 1 and 10 mM (in 0.1 M KCl) were recorded at different scan rates (Figure 2). For both concentrations a peak to peak separation value close to reversibility was shown. The currents are also those predicted for linear diffusion using the Randles Sevcik equation. Thus for the magnitude of currents passed these macrodisk electrodes show metal like behaviour at the concentrations employed.

Figure 2. Cyclic voltammograms for the reduction of (a) 1 mM and (b) 10 mM Ru(NH3)63+ in 0.1 M KCl at a pBDD 1 mm diameter disk electrode

References

- L. Hutton, M. E. Newton, P. R. Unwin and J. V. Macpherson, Anal. Chem., 2009, 81(3), 1023–1032.