SWNT Growth

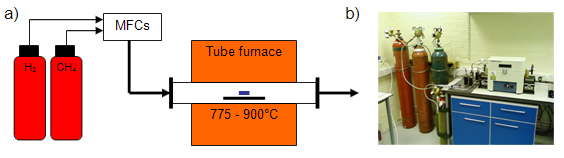

We synthesise carbon nanotubes using a process known as catalysed chemical vapour deposition (cCVD). A cCVD system is essentially a high-temperature tube furnace through which a controlled mixture of gases is passed. We have 2 such systems, which we have designed and constructed ourselves. A schematic and photograph of one of these are shown in Figure 1.

Figure 1: (a) Schematic of the cCVD setup for SWNT growth, b) one such cCVD system at Warwick.

We grow carbon nanotubes on a variety of surfaces, primarily silicon. Substrate chips are first covered with a suitable catalyst material (e.g. iron); this can be carried out either by sputter deposition of a thin film of metal (which forms catalytic nanoparticles on heating) or direct deposition of catalytic nanoparticles (e.g. ferritin particles).

Once the catalyst has been deposited, the substrates are placed into a sealed quartz tube which runs through the centre of a tube furnace. The furnace is switched on and heated up to the growth temperature, whilst hydrogen is passed over the substrate. At the growth temperature, a carbon source (typically methane) is introduced into the tube in addition to the hydrogen. The gas flow and the furnace temperature are maintained for the growth time (typically ~ 5 minutes), after which the system is allowed to cool under a flow of hydrogen only.

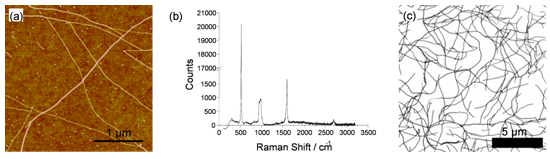

The cCVD process generates randomly arranged networks of carbon nanotubes lying flat on the surface of substrates. Characterisation of such networks is carried out using AFM, FE-SEM and micro-Raman spectroscopy (Figure 2). AFM shows that most of the nanotubes have diameters in the range 1 – 3 nm, corresponding to single-walled carbon nanotubes (SWNTs). FE-SEM allows fast and clear visualisation of the network structure over large areas, allowing the density of the network to be extracted. Micro-Raman spectroscopy provides detailed information regarding the particular structures present.

Figure 2: (a) AFM, (b) micro-Raman and (c) FE-SEM characterisation of a typical growth using sputtered Fe catalyst.

Carbon nanotube networks with different densities possess different electrical properties, this is important when using the networks to fabricate electrical devices. It is therefore desirable to be able to control the densities produced using the cCVD process. Such control is possible by controlling the methane:hydrogen flow ratio during growth and the growth temperature.

References

J. P. Edgeworth, N. R. Wilson and J. V. Macpherson, Small 2007, 3(5), 860-870.