Lightweight Electric Go Kart

This project was carried out by 4th Year Engineering Undergraduates from the University of Warwick, applying the lightweighting concepts and research outcomes from the WMG centre High Value Manufacturing Catapult. The student team are tasked with designing and building an electric go-kart to compete at the annual Electric Vehicle Grand Prix (EVGP) in Indiana, U.S.A. The event is run by Purdue University and takes place over in April and May over two races; one at Purdue Grand Prix Track and the other at the world famous Indianapolis Motor Speedway. The event aims to kickstart innovation within the education sector, helping to boost development of exciting new designs and technologies for use in the automotive world.

The objective of this project was to significantly reduce the weight of the team's electric go kart while maintaining functionality and robustness.

- Identify key components which can be light-weighted

- Identify alternative materials and assembly options

- Model components in new materials to evaluate weight reductions and predicted functional performance

- Prototype weight-reduced components and verify functionality

Outcomes:

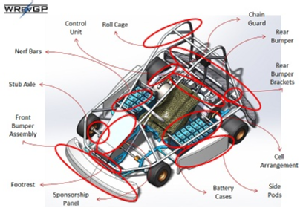

Ten components were identified as offering significant weight reductions e.g. nerf bars, stub axles, rear axle, roll cage, bumpers. Alternatives to steel and aluminium were evaluated e.g. magnesium, titanium, maraging steel, tritek polypropylene composite. The overall weight of the vehicle was reduced by 20% while maintaining structural integrity and improving crash worthiness. In addition, the weight distribution was optimised front-to-rear and left-to-right.