Looking Deeper into the Samsung Galaxy (Note 7)

Case Study: Looking Deeper into the Galaxy (Note 7)

Lithium-ion batteries are statistically safe, with a 1 in 10 million failure rate established during the manufacturing and such failures are considered an exception and not a reliability problem. To eliminate these effectively, we need techniques to fully understand their root causes.

In 2006, a 1-in-200,000 failure rate triggered a recall of almost six million Lithium-ion battery packs used in several brands of notebook computers. Sony, the maker of the lithium-ion cells in question, pointed out that on rare occasions microscopic metal particles may come into contact with other parts of the battery cell, leading to a short circuit within the cell. In 2013, Boeing had its newest and most advanced aircraft, the 787 Dreamliner, globally grounded due to incidences of fire that emanated from a battery powering an APU (auxiliary power unit) on board flight JA829. At least three other reported incidences have affected other airliners with a significant fleet of 787 aircrafts. There is a continued drive for faster innovations in Li-ion cell formats, regardless of type and dimension, to meet advanced performance criteria.

Within Li-ion cells an internal short circuit can generate sufficient heat to initiate exothermic side reactions involving energy dense and sometimes volatile components within the cell—when these proceed out of control they cause a thermal runaway resulting in fires.

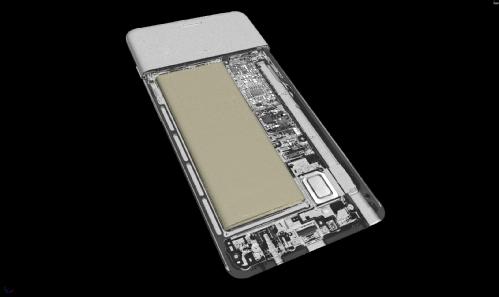

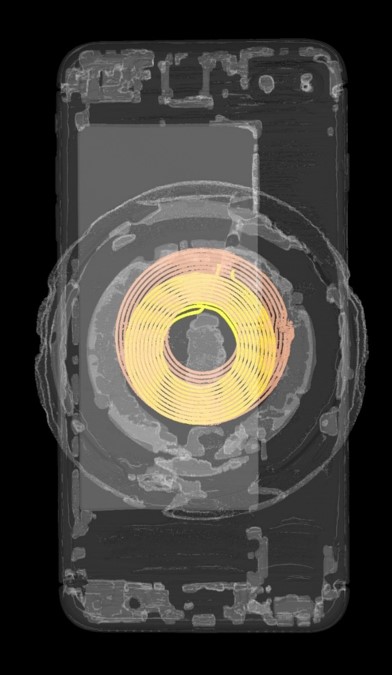

The device was brought to CiMAT at the University of Warwick initially to firstly analysed the region of interest (ROI) inside the whole sample without dismantling the device, scanning both the uncharged and partially charged battery. The tomography scanners used for this study was: X-Tek (Nikon) X-H 225/320 LC. The phone was scanned twice: (i) with the battery discharged; and (ii) with the battery partially charged. The device was positioned consistently to maximise magnification and reduce potential artefacts.

In order to obtain a satisfactory resolution, the device was scanned in two phases—‘Top and

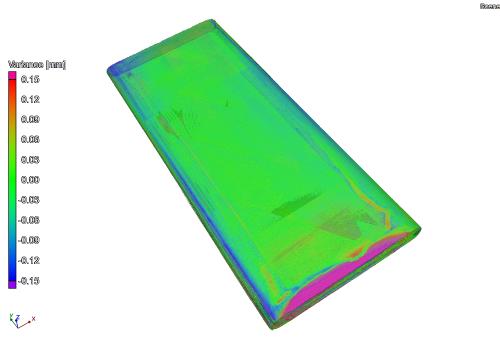

Bottom’ and stitched together. Conditions for the top and bottom scans were the same with the individual scans of the battery partially charged having slightly different settings to provide optimum results. A fixture was used in all of the scans to ensure the position of the devise and avoid micro movement during the 360 degrees rotation. The series of variables selected are based on the scanned material, the capabilities of the CT system and the required resolution. The settings and the positioning of the part was selected for maximum magnification resulting in a voxel size and resolution of 52 um.

X-ray tomography confirmed reported findings of the upper corner deformation and compression of the battery contents, leaving minimal volume within the pouch using this type of cell design.

Publications: Melanie J. LoveridgeI, Guillaume Remy, Nadia Kourra, Ronny Genieser, Anup Barai, Mike J. Lain, Yue Guo, Mark Amor-Segan, Mark A. Williams, Tazdin Amietszajew, Mark Ellis, Rohit Bhagat and David Greenwood. Case Report, Looking Deeper into the Galaxy (Note 7), Batteries (ISSN 2313-0105; CODEN: BATTAT). https://doi.org/10.3390/batteries4010003