Electric Motor

Case Study: Electric Motor

Study was to create virtual visualisation of a BOSCH E-motor using X-ray CT in order to avoid dismantling or destroying any part of the sample.

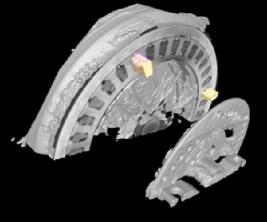

The motor was scanned using our Nikon 450RT Walking bay using our Curved Linear Detector Array (CLDA).

Dimension of the E-motor is about 450mm diameter including the tyre around the rim, the thickness of the material (rotor +stator (winding and segment)) is about 2x 45mm of magnetic steel and copper.

Resolution of 241µm using CLDA detector.

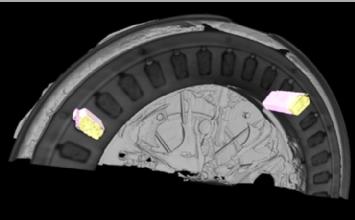

Main interest was to evaluate the winding quality within each segment of the stator and the potential air gap between rotor and stator. This evaluation is nearly impossible when physically dismantling the E-motor; any release of pressure when loosing up the shaft will generate a movement of the rotor changing the position and therefore the air gap.

Using high power X-ray CT we were able to characterise the winding within the stator and we were able to visualise the air gap between the 2 components.

|

|

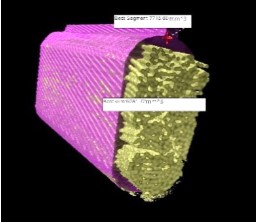

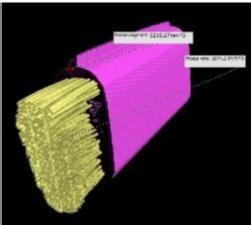

Isolation of the best and worse segment with volume evaluation

Back view |

Front View |

Top image best segment Segment volume space: 7716mm3 Wire winding volume filling: 6281mm3 |

Bottom image worse segment Segment volume space: 6210mm3 Wire winding volume filling: 3074mm3

|