Warwick Moto’s electric superbike build racing ahead despite lockdown

· A team of 25 students who formed Warwick Moto are designing, building and developing an electric superbike which was due to race this summer

· Although coronavirus means plans are on hold, not everything is, as the University of Warwick students have been meeting virtually and redesigned a vital part of the chassis

· The component is 1.5kg lighter, and can be assembled off-site as labs are closed during the Covid-19 pandemic

Warwick Moto team, consisting of 25 Warwick students aren’t letting the pandemic get in the way of designing, building and developing the electric superbike, as they’re doing it virtually from home.

It was hoped that the Warwick Moto team would see their electric superbike Aurora race this summer with racer Tom Weeden racing it for them. Although plans are on hold due to the current pandemic, students have tried to make the most of their time during lockdown by carrying out virtual meetings to progress on the project as a whole.

Meeting online, the 25 students from a range of Departments including: WMG, School of Engineering, Computer Science, Physics and Maths have redesigned a vital part of the superbike chassis, the subframe.

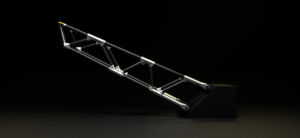

The subframe is an integral part of the motorcycle geometry, therefore, has an impact on handling characteristics of the superbike by defining the seating position of the rider. The subframe for Aurora will also package a critical powertrain component, the inverter for the 3-phase 150 kW (200 bhp) electric motor along with some low voltage components.

The team utilised previously gathered data from the strip, measure and weigh activities performed in November 2019 before lockdown, with the help of the metrology team at WMG. This exercise enabled them to define the necessary constraints for the position of the subframe. They have managed to make it 1.5kg lighter than a stock Honda Fireblade subframe and roughly 300g than a racing one. It’s made using carbon fibre and aluminium parts as opposed to just aluminium, reducing weight and increasing the overall stiffness.

Nesta Ferguson and Aneesh Jois, two first year School of Engineering students, have led the design and engineering cycle behind the subframe while discussing ideas, constraints and risks with the rest of the team through online meetings.

Aman Surana, a School of Engineering student and the Chief Engineer for the Warwick Moto team comments:

“We wanted to make the most out of lockdown and try to use this setback as an opportunity to enhance the bike instead. The team’s design intent was to create something simple, easy to assemble and the ability to be built off-site.

“The current global situation demands for concepts that can be built while maintaining social distancing, this new design helps us achieve that as it can be put together by a single person. As a result, we can utilise workshop time for other critical activities.

“We believe this concept could be used by other racing enthusiasts, as it’s made using stock carbon fibre tubes cut to size and bonded to aluminium joining nodes, where the contact surfaces have been sanded to increase bond strength and area. Moreover, it has the potential to be used on other parts of the superbike at a much lower cost than traditional composite only components.”

Having spent the last 3 months to continuously come up with various load-cases to simulate and optimise the subframe structure, the team have used techniques such as shape optimisation to minimise the amount of material used.

The team are still hoping to be able to test the bike in winter, as a competition between University teams is still hoping to take place early next year, however their long-term objective is to compete with a podium qualifying time at the Isle of Man TT 2022.

Rock West Composites are donating the raw material required for this concept along with advice to improve things like bond strength from their years of experience with composites. Xometry Europe have supported the team by providing on-demand manufacturing services that have enabled the manufacture of the joining nodes. The team will be able to assemble this concept off-site with the support of Rock West Composites and Xometry Europe.

Significant support from industrial partners such as High Value Manufacturing (HVM) Catapult team at WMG, MUPO Race Suspension, Michelin Tyre PLC, DYMAG Performance Wheels, MIVOLT, Demon Tweeks, SITRAmoto and Rajputana Custom Motorcycles have immensely helped the team, for which they would like to thank them all for.

To support the team making their first electric bike, you can sponsor them or donate to them here: https://www.justgiving.com/crowdfunding/warwickmoto

Follow their journey:

Instagram: https://www.instagram.com/warwick.moto/

Facebook: https://www.facebook.com/warwickmotoracing/

LinkedIn: https://www.linkedin.com/company/warwick-moto/

ENDS

5 AUGUST 2020

NOTES TO EDITORS

Video of the team during lockdown available to view at: https://www.youtube.com/watch?v=BLyj7fzbIw0&feature=youtu.be

High-res images available credit to WMG, University of Warwick at:

Caption: A render of the component of the chassis the team redesigned and made during lockdown. Credit: Warwick Moto, University of Warwick

Caption: A render of the component of the chassis the team redesigned and made during lockdown. Credit: Warwick Moto, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/subframe_renders_bb_2020-jul-27_09-44-12pm-000_customizedview19308728638_png.png

Caption: A render of the component of the chassis the team redesigned and made during lockdown. (White background)

Credit: Warwick Moto, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/subframe_renders_bb_2020-jul-27_09-44-24pm-000_customizedview19308728638_png.png

Caption: A render of the component of the chassis the team redesigned and made during lockdown. (White background)

Credit: Warwick Moto, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/june2020/aurora_render_2.png

Caption: The front of Aurora.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/team-meeting2.png

Caption: Some of the team in a virtual meeting on teams during lockdown.

Credit: Warwick Moto, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/team-meetingcall.png

Caption: Some of the team in a virtual meeting on teams during lockdown.

Credit: Warwick Moto, University of Warwick

THE FOLLOWING IMAGES WERE TAKEN BEFORE THE CORONAVIRUS PANDEMIC

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/img_2404.jpg

Caption: Students and an Engineer carrying out the Strip, Measure and Weigh Activities. Credit: Warwick Moto, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/img_2367.jpg

Caption: 3D Scanning being carried out by WMG Metrology Team. Credit: Warwick Moto, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/february2020/tom_20.jpg

Caption: The full team of students and academics with the driver, Tom Weeden

https://warwick.ac.uk/services/communications/medialibrary/images/february2020/tom_04.jpg

Caption: The students and some academics working on the Warwick Moto team with the bike

https://warwick.ac.uk/services/communications/medialibrary/images/february2020/tom_08.jpg

Caption: Tom Weeden, left with students and the bike

https://warwick.ac.uk/services/communications/medialibrary/images/february2020/tom_18.jpg

Caption: Tom Weeden, on the electric superbike

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920531221

E-mail: alice.j.scott@warwick.ac.uk

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920531221

E-mail: alice.j.scott@warwick.ac.uk