Departmental news

PhD Students Gain Hands-On Battery Engineering Experience at WMG's Battery School

PhD students, and future battery engineers, from leading universities across the UK joined us for a special week-long Battery School at our Energy Innovation Centre, for the Faraday Institution, recently.

In our role as the Electrical Energy Storage APC Spoke, our battery experts facilitated a mix of lectures and practical sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

In our role as the Electrical Energy Storage APC Spoke, our battery experts facilitated a mix of lectures and practical sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

Fran Long, Education and Training Co-ordinator, at The Faraday Institution, said: “The WMG Battery School, at the University of Warwick, gave our PhD students a wonderful week of detailed theory and practice with an abundance of high quality lectures and ‘hands-on’ lab sessions.

“We would like to thank all of the WMG staff involved in making this such a valuable experience for the students. Encouraging the next generation of engineers into battery related careers, is extremely important for the UK’s electrification sector.”

The Faraday Institution is the UK’s independent institute for electrochemical energy storage science and technology, supporting research, training, and analysis. It brings together scientists and industry partners on research projects to reduce battery cost, weight, and volume; to improve performance and reliability; and to develop whole-life strategies from mining to recycling to second use.

The Battery School is part of the Faraday Battery Challenge, along with the UK Battery Industrialisation Centre (of which WMG was part of the winning consortium).

Find out more about our Energy Innovation Centre here.

RESOLVE prototypes shape future of electric urban commuting

The future of daily urban commuting could be small, lightweight Electric L-category Vehicles (ELVs). A cost effective, energy efficient and comfortable alternative to traditional cars in cities, is at the heart of the €6.92m RESOLVE project, which included WMG at the University of Warwick.

The future of daily urban commuting could be small, lightweight Electric L-category Vehicles (ELVs). A cost effective, energy efficient and comfortable alternative to traditional cars in cities, is at the heart of the €6.92m RESOLVE project, which included WMG at the University of Warwick.

The European project – named ‘Range of Electric Solutions for L-category Vehicles’ – designed and developed two stylish tilting four-wheeler prototype ELVs with leading European manufacturers Piaggio and KTM. These demonstrators were unveiled, and presented to representatives from the European Commission, at an event in Brussels in April 2018.

WMG was one of fourteen partners in the project, which included leading names from industry and research such as Piaggio, KTM, Bosch, Ricardo, the Austrian Institute of Technology, and the University of Florence.

£5.6m Vehicle-2-Grid project develops charging technology in real world

Electric vehicle charging infrastructure on UK roads is to be advanced, thanks to a new £5.6 million project – funded by Innovate UK – to develop Vehicle-2-Grid (V2G)Link opens in a new window technologies, involving WMG at the University of Warwick.

For three years from April 2018, the EV-elocity consortium will conduct a project to demonstrate and develop V2G technology across a variety of UK locations, including airports and business parks – with the aim of proving its viability and worth to business and the wider public.

Researchers at WMG, led by vehicle electrification and energy storage expert Dr James Marco, will build a techno-economic model of how V2G will be viable within the UK. A key innovation will be the inclusion of new models of battery degradation within the analysis that will underpin new methods to optimise the vehicle’s battery system.

Researchers at WMG, led by vehicle electrification and energy storage expert Dr James Marco, will build a techno-economic model of how V2G will be viable within the UK. A key innovation will be the inclusion of new models of battery degradation within the analysis that will underpin new methods to optimise the vehicle’s battery system.

Dr Marco’s team will also analyse real-world usage data from a range of different electric fleet vehicles as they are used within a V2G context.

The project will break new ground in helping consumers, businesses and infrastructure providers to financially benefit from adapting their charging behaviour and vehicle use.

In doing so, the project will help to further accelerate and incentivise the transition from traditional fuel sources to electric vehicles.

New sensor tech for commercial Lithium-ion batteries finds they can be charged 5 times faster

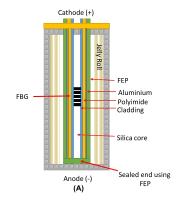

Researchers at WMG at the University of Warwick have developed a new direct, precise test of Lithium-ion batteries’ internal temperatures and their electrodes potentials and found that the batteries can be safely charged up to five times faster than the current recommended charging limits. The new technology works in-situ during a battery’s normal operation without impeding its performance and it has been tested on standard commercially available batteries. Such new technology will enable advances in battery materials science, flexible battery charging rates, thermal and electrical engineering of new battery materials/technology and it has the potential to help the design of energy storage systems for high performance applications such as motor racing and grid balancing.

Researchers at WMG at the University of Warwick have developed a new direct, precise test of Lithium-ion batteries’ internal temperatures and their electrodes potentials and found that the batteries can be safely charged up to five times faster than the current recommended charging limits. The new technology works in-situ during a battery’s normal operation without impeding its performance and it has been tested on standard commercially available batteries. Such new technology will enable advances in battery materials science, flexible battery charging rates, thermal and electrical engineering of new battery materials/technology and it has the potential to help the design of energy storage systems for high performance applications such as motor racing and grid balancing.

If a battery becomes over heated it risks severe damage particularly to its electrolyte and can even lead to dangerous situations where the electrolyte breaks down to form gases than are both flammable and cause significant pressure build up. Overcharging of the anode can lead to so much Lithium electroplating that it forms metallic dendrites and eventually pierce the separator causing an internal short circuit with the cathode and subsequent catastrophic failure.