How amorphous carbon breaks: atomistic models and machine learning

Student: Fraser Birks

Project supervisors: James Kermode; Albert Bartok-Partay

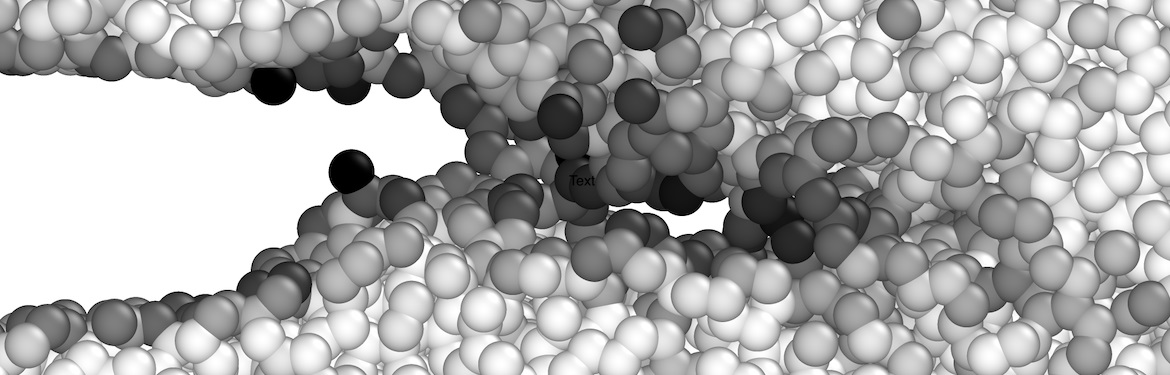

Summary: Amorphous carbon (a-C) has many industrial applications, from electrochemical sensors to wear-resistant coatings. Fracture plays a crucial role in the degradation of its performance, with coatings often failing by shear or flexural cracks. This means that as well as being able to predict fracture toughness, it is crucial to understand the response to mixed tensile and shear loads and predict the trajectory of cracks. In this project, we will build on data-driven approaches that use machine learning techniques to produce quantum mechanically accurate models at a fraction of the cost, and use them to produce a complete description of crack growth in a-C.

Background: Only atomistic simulations have the capability of being truly predictive, since larger scale models such as X-FEM, phase-field and others invariably include empirical crack growth algorithms. The project will involve collaboration with Prof. Lars Pastewka at the University of Freiburg, with whom the project supervisor has recently shown that atomistic modelling can be used to produce quantitative predictions of the fracture toughness of a-C in good agreement with experiment [1]. This work used standard continuum linear elastic boundary conditions, and thus required large atomistic domains, preventing extension to crack path selection or mixed-mode loading.

The project will also employ a novel numerical continuation enhanced flexible boundary condition scheme, NCFlex, that has recently been developed by the supervisor with Dr Maciej Buze (University of Birmingham) [2] who will also be involved in the team. The approach fuses materials modelling techniques with numerical analysis to produce bifurcation diagrams for cracks.

Fracture of a-C represents a “sweet spot” where the process zone is nanoscale and hence accessible to direct atomistic simulation, but still of immediate technological importance. It is currently the only isotropic material whose fracture properties can be studied with predictive atomistic methods. For truly predictive models, improved accuracy is also needed in the interatomic potential. In this project, we will build on data-driven approaches such as [3] that use machine learning techniques to produce QM-accurate force fields at a fraction of the cost, and go beyond tensile loading simulations to produce a complete description of crack growth in a-C.

References

[1] S. M. Khosrownejad, J. R. Kermode, and L. Pastewka, Phys. Rev. Mater. 5, 023602 (2021).

[2] M. Buze and J. R. Kermode Phys. Rev. E 103, 033002 (2021).

[3] V. L. Deringer and G. Csányi, Phys. Rev. B 95, 094203 (2017).