Departmental news

Charging ahead!

WMG is pleased to announce that its Battery School is now officially supported by the Faraday Institution.

WMG is pleased to announce that its Battery School is now officially supported by the Faraday Institution.

In its role as the Electrical Energy Storage APC Spoke, WMG’s battery experts together with guest lecturers facilitate a mix of presentations and practical hands-on lab sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

The new collaborative Battery School was officially opened by Neil Morris, CEO of the Faraday Institution, with the first session held for 25 PhD students and future battery engineers, in June.

The Faraday Institution is the UK’s independent institute for electrochemical energy storage science and technology, supporting research, training, and analysis. It brings together scientists and industry partners on research projects to reduce battery cost, weight, and volume; to improve performance and reliability; and to develop whole-life strategies from mining to recycling to second use.

The Battery School is situated at WMG’s Energy Innovation Centre – the largest facility of its kind in the UK. Find out more about the Energy Innovation Centre here.

How you charge your mobile phone could compromise its battery lifespan

Researchers at WMG at the University of Warwick have found that use of inductive charging, whilst highly convenient, risks depleting the life of mobile phones using typical LIBs (Lithium-ion batteries)

Consumers and manufacturers have ramped up their interest in this convenient charging technology, abandoning fiddling with plugs and cables in a favour of just setting the phone directly on a charging base.

Standardisation of charging stations, and inclusion of inductive charging coils in many new smartphones has led to rapidly increasing adoption of the technology. In 2017, 15 automobile models announced the inclusion of consoles within vehicles for inductively charging consumer electronic devices, such as smartphones – and at a much larger scale, many are considering it for charging electric vehicle batteries.

Inductive charging enables a power source to transmit energy across an air gap, without the use of connecting wire but one of the main issues with this mode of charging is the amount of unwanted and potentially damaging heat that can be generated. There are several sources of heat generation associated with any inductive charging system – in both the charger and the device being charged. This additional heating is made worse by the fact that the device and the charging base are in close physical contact, any heat generated in one device may be transferred to the other by simple thermal conduction and convection.

In a smartphone, the power receiving coil is close to the back cover of the phone (which is usually electrically non-conductive) and packaging constraints necessitate placement of the phone’s battery and power electronics in close proximity, with limited opportunities to dissipate heat generated in the phone, or shield the phone from heat generated by the charger. It has been well-documented that batteries age more quickly when stored at elevated temperatures and that exposure to higher temperatures can thus significantly influence the state-of-health (SoH) of batteries over their useful lifetime.

The rule of thumb (or more technically the Arrhenuis equation) is that for most chemical reactions, the reaction rate doubles with each 10 °C rise in temperature. In a battery, the reactions which can occur include the accelerated growth rate of passivating films (a thin inert coating making the surface underneath unreactive) on the cell’s electrodes. This occurs by way of cell redox reactions, which irreversibly increase the internal resistance of the cell, ultimately resulting in performance degradation and failure. A lithium ion battery dwelling above 30 °C is typically considered to be at elevated temperature exposing the battery to risk of a shortened useful life.

Guidelines issued by battery manufacturers also specify that the upper operational temperature range of their products should not surpass the 50−60 °C range to avoid gas generation and catastrophic failure.

These facts led WMG researchers to carry out experiments comparing the temperature rises in normal battery charging by wire with inductive charging. However the WMG were even more interested in inductive charging when the consumer misaligns the phone on the charging base. To compensate for poor alignment of the phone and the charger, inductive charging systems typically increase the transmitter power and/or adjust their operating frequency, which incurs further efficiency losses and increases heat generation.

This misalignment can be a very common occurrence as the actual position of the receiving antenna in the phone is not always intuitive or obvious to the consumer using the phone. The WMG research team therefore also tested phone charging with deliberate misalignment of transmitter and receiver coils.

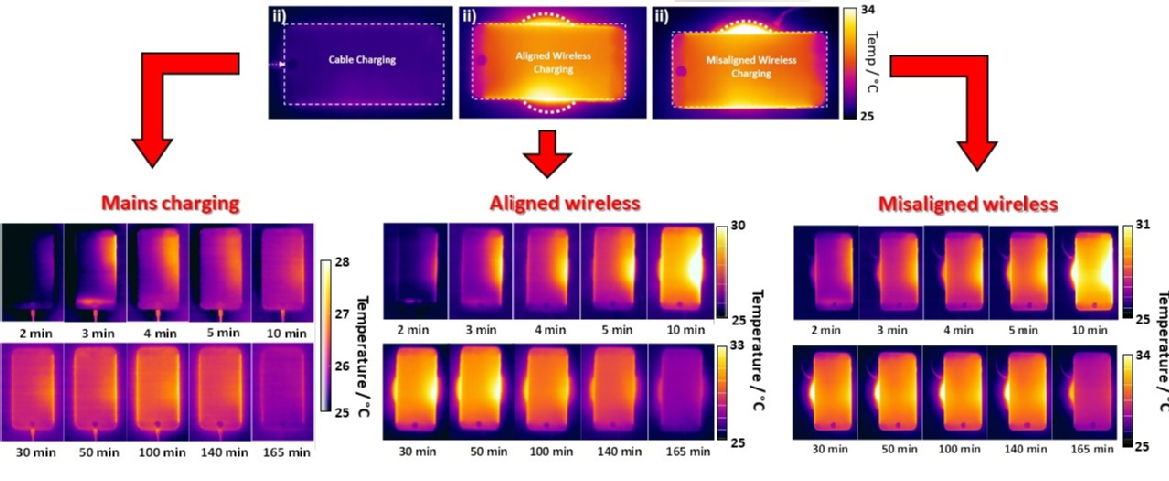

All three charging methods (wire, aligned inductive and misaligned inductive) were tested with simultaneous charging and thermal imaging over time to generate temperature maps to help quantify the heating effects. The results of those experiments have been published in the journal ACS Energy Letters in an article entitled “Temperature Considerations for Charging Li-Ion Batteries: Inductive versus Mains Charging Modes for Portable Electronic Devices.”

The graphics with this press release illustrates three modes of charging, based on (a) AC mains charging (cable charging) and inductive charging when coils are (b) aligned and (c) misaligned. Panels i and ii show a realistic view of the charging modes with a snapshot of the thermal maps of the phone after 50 min of charging. Regardless of the mode of charging, the right edge of the phone showed a higher rate of increase in temperature than other areas of the phone and remained higher throughout the charging process. A CT scan of the phone showed that this hotspot is where the motherboard is located In the case of the phone charged with conventional mains power, the maximum average temperature reached within 3 hours of charging did not exceed 27 °C.

The graphics with this press release illustrates three modes of charging, based on (a) AC mains charging (cable charging) and inductive charging when coils are (b) aligned and (c) misaligned. Panels i and ii show a realistic view of the charging modes with a snapshot of the thermal maps of the phone after 50 min of charging. Regardless of the mode of charging, the right edge of the phone showed a higher rate of increase in temperature than other areas of the phone and remained higher throughout the charging process. A CT scan of the phone showed that this hotspot is where the motherboard is located In the case of the phone charged with conventional mains power, the maximum average temperature reached within 3 hours of charging did not exceed 27 °C.

In contrast this for the phone charged by aligned inductive charging, the temperature peaked at 30.5 °C but gradually reduced for the latter half of the charging period. This is similar to the maximum average temperature observed during misaligned inductive charging.

In the case of misaligned inductive charging, the peak temperature was of similar magnitude (30.5 °C) but this temperature was reached sooner and persisted for much longer at this level (125 minutes versus 55 minutes for properly aligned charging).

Also noteworthy was the fact that the maximum input power to the charging base was greater in the test where the phone was misaligned (11W) than the well-aligned phone (9.5 W). This is due to the charging system increasing the transmitter power under misalignment in order to maintain target input power to the device. The maximum average temperature of the charging base while charging under misalignment reached 35.3 °C, two degrees higher than the temperature detected when the phone was aligned, which achieved 33 °C. This is symptomatic of deterioration in system efficiency, with additional heat generation attributable to power electronics losses and eddy currents.

The researchers do note that future approaches to inductive charging design can diminish these transfer losses, and thus reduce heating, by using ultrathin coils, higher frequencies, and optimized drive electronics to provide chargers and receivers that are compact and more efficient and can be integrated into mobile devices or batteries with minimal change.

In conclusion, the research team found that inductive charging, whilst convenient, will likely lead to a reduction in the life of the mobile phone battery. For many users, this degradation may be an acceptable price for the convenience of charging, but for those wishing to eke out the longest life from their phone, cable charging is still recommended.

ENDS

26 JUNE 2019

NOTES FOR EDITORS

While one specific model of mobile phone was used to conduct the tests the issues raised obviously apply to all phones or portable devices now or in the future that seek to use inductive charging.

High-res image available at: https://warwick.ac.uk/services/communications/medialibrary/images/june2019/iphone_charging_mode_2.jpg

Credit: WMG, University of Warwick

Paper available to view at: https://pubs.acs.org/doi/10.1021/acsenergylett.9b00663

List of Authors (all WMG) include:

Melanie. J. Loveridge

Chaou C. Tan

Faduma M. Maddar

Guillame Remy

Mike Abbott

Shaun Dixon

Richard McMahon

Ollie Curnick

Mark Ellis

Mike Lain

Anup Barai

Mark Amor-Segan

Rohit Bhagat

Dave Greenwood

WMG partners with Triumph Motorcycles in electric motorcycle project

Triumph Motorcycles has announced a new collaboration with UK industry experts, academic leaders including WMG at the University of Warwick, and Innovate UK, to develop specialist electric motorcycle technology which will provide significant input into potential future electric motorcycle offers from Triumph. This two-year project (TRIUMPH TE-1) also includes partnership work with Williams Advanced Engineering, and Integral Powertrain Ltd.

Triumph Motorcycles has announced a new collaboration with UK industry experts, academic leaders including WMG at the University of Warwick, and Innovate UK, to develop specialist electric motorcycle technology which will provide significant input into potential future electric motorcycle offers from Triumph. This two-year project (TRIUMPH TE-1) also includes partnership work with Williams Advanced Engineering, and Integral Powertrain Ltd.

This new collaboration will combine Triumph’s globally-renowned motorcycle expertise with advanced automotive-based capabilities to generate technological innovation for future electric motorcycles.

“This new collaboration represents an exciting opportunity for Triumph and its partners to be leaders in the technology that will enable the electrification of motorcycles, which is driven by customers striving to reduce their environmental impact, combined with the desire for more economical transportation, and changing legislation,” said Nick Bloor, Triumph CEO. “Project Triumph TE-1 is one part of our electric motorcycle strategy, focused on delivering what riders want and expect from their Triumph, which is the perfect balance of handling, performance and usability.”

A unique collaboration between industry experts, academic leaders and Innovate UK

Project Triumph TE-1 now represents a ground-breaking collaboration between Triumph Motorcycles and the UK’s electrification experts, each of whom will create innovations in their own areas:

- Triumph Motorcycles will lead the project, providing advanced motorcycle chassis design and engineering expertise, manufacturing excellence and pioneering functional safety systems, as well as defining electric drivetrain power delivery characteristics.

- WMG, at the University of Warwick will provide electrification expertise, and the critical vision to drive innovation from R&D to commercial impact, through modelling and simulation based on future market needs.

- Williams Advanced Engineering will provide industry-leading lightweight battery design and integration capability, using its test and development facilities to deliver an innovative battery management system combined with vehicle control unit.

- Integral Powertrain Ltd’s e-Drive Division will lead the development of bespoke power-dense electric motors and a silicon carbide inverter, integrating both into a singular motor housing.

- Innovate UK, the government agency that promotes science and technology programmes expected to grow the UK economy, will support the partners and administer funds. This forms part of the BEIS modern funding strategy with the aim of creating a market-leading UK electric vehicle capability.

A two-year project focused on developing technical innovation and advanced electric motorcycle capabilities

The project will be organised into four main phases, with one of its key aims being increased systems integration. By developing individual components of automotive-based electric drivetrains and optimising them into innovative combined units, the project aims to deliver sophisticated electric motorcycle systems which reduce mass, complexity and package requirements.

Triumph Motorcycles will work alongside the partner organisations to accelerate joint expertise in the packaging and safety of batteries, optimum electric motor sizing and packaging, the integration of braking systems including regenerative braking, and advanced safety systems. The innovation and capabilities developed in these areas will input into Triumph’s future electric motorcycle strategy.

The Project Triumph TE-1 partnership, with the support of Innovate UK, is focused on facilitating the creation of:

- Electric motorcycle capability that meets the needs of customers seeking lower environmental impact transportation, delivering against the UK’s focus on reducing emissions

- Strong, commercially viable and sustainable partnerships with UK industry manufacturers and supply chains

- Expertise and capability within the UK workforce, creating jobs and a talent base that both ensures sustainable employment and drives the UK’s reputation and influence on the world stage.

Professor David Greenwood, Professor of Advanced Propulsion Systems at WMG, University of Warwick said: “Electric motorcycles will have a vital role to play in future transport across the globe - delivering reduced congestion and improved urban air quality as well as easing parking. They will also be great to ride, with copious, easily controlled torque delivered smoothly at all road speeds. WMG has experience of battery technology and vehicle electrification for road, rail, sea and air which it will bring to this exciting sector. Our expert team will lead the modelling and simulation work within the project, to ensure the vehicles are safe and efficient without compromise to dynamic performance.”

“The team at Williams Advanced Engineering is looking forward to applying our expertise in the electrification of transport with our partners,” said Craig Wilson, Managing Director of Williams Advanced Engineering. “Williams has powered a number of world-renowned electric vehicles already and this will be a significant further step in our work by taking that knowledge onto two wheels.”

“Integral Powertrain has always pushed the boundaries of e-drive technology working with clients to find the best solution to meet their exact requirements”, said Andrew Cross, Chief Technical Officer at Integral Powertrain Ltd. “This project will draw upon the extensive motor and EV experience gained over the past 20 years working with major OEMs and Tier 1 suppliers in the automotive and motorsport sectors. We are extremely pleased to be supporting Triumph Motorcycles with their future electrification strategy and in a project where we can apply our experience to engineer an extremely power dense, efficient and highly integrated motorcycle electric drive.”

Steve Sargent, Triumph’s Chief Product Officer said “Our future product strategy is focused on delivering the most suitable engine platforms for the changing landscape of customer needs, and we see a Triumph electric powertrain as a significant requirement alongside our signature twin and triple cylinder engines. As part of our electric motorcycle initiative, Project Triumph TE-1 represents an exciting collaboration that will provide valuable input into our future line-up. We are incredibly pleased to have the support of OLEV and Innovate UK, and to be working together with the UK’s electrification experts and academic leaders, in an endeavour that ultimately is focused on the future prosperity of British industry, and the future of motorcycling.”

PhD Students Gain Hands-On Battery Engineering Experience at WMG's Battery School

PhD students, and future battery engineers, from leading universities across the UK joined us for a special week-long Battery School at our Energy Innovation Centre, for the Faraday Institution, recently.

In our role as the Electrical Energy Storage APC Spoke, our battery experts facilitated a mix of lectures and practical sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

In our role as the Electrical Energy Storage APC Spoke, our battery experts facilitated a mix of lectures and practical sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

Fran Long, Education and Training Co-ordinator, at The Faraday Institution, said: “The WMG Battery School, at the University of Warwick, gave our PhD students a wonderful week of detailed theory and practice with an abundance of high quality lectures and ‘hands-on’ lab sessions.

“We would like to thank all of the WMG staff involved in making this such a valuable experience for the students. Encouraging the next generation of engineers into battery related careers, is extremely important for the UK’s electrification sector.”

The Faraday Institution is the UK’s independent institute for electrochemical energy storage science and technology, supporting research, training, and analysis. It brings together scientists and industry partners on research projects to reduce battery cost, weight, and volume; to improve performance and reliability; and to develop whole-life strategies from mining to recycling to second use.

The Battery School is part of the Faraday Battery Challenge, along with the UK Battery Industrialisation Centre (of which WMG was part of the winning consortium).

Find out more about our Energy Innovation Centre here.

New report says UK electric vehicle battery industry could be worth £2.7 billion per year for UK chemical companies

A new report published today Monday 25th June 2018 shows that UK companies are well-placed to supply valuable materials needed for batteries to be built in UK – a potential £2.7 billion per year business opportunity. The report commissioned by WMG at the University of Warwick, was launched to the Chemical Industry Association at the Chemistry Growth Partnership meeting in London, chaired by Steve Foots, Chief Executive of Croda, and attended by Richard Harrington MP.

A new report published today Monday 25th June 2018 shows that UK companies are well-placed to supply valuable materials needed for batteries to be built in UK – a potential £2.7 billion per year business opportunity. The report commissioned by WMG at the University of Warwick, was launched to the Chemical Industry Association at the Chemistry Growth Partnership meeting in London, chaired by Steve Foots, Chief Executive of Croda, and attended by Richard Harrington MP.

The research underpinning the report brought together experts and data from the automotive battery industry and chemicals industry, working in the context of the UK’s Industrial Strategy, points to a large UK battery manufacturing industry opportunity. The report was funded by EPSRC, commissioned and managed by WMG at the University of Warwick acting in their role as the Advanced Propulsion Centre Electrical Energy Storage Spoke, and delivered in partnership with E4tech. WMG’s Professor David Greenwood, one of the report’s authors said:

“This report details a massive opportunity to grow a UK battery chemicals industry and related supply chain. The UK’s Industrial Strategy identified battery development and manufacture as one of the four initial Grand Challenges to coalesce industrial activity upon high growth opportunities. Battery pack manufacturing for electric vehicles (EVs) will logically take place close to the point of vehicle assembly since packs are hard to transport. This in turn implies that the battery cells which make up the packs will best be manufactured in (or close to) the UK. This could also mitigate the loss of vehicle engine production.”

“However for cell production to occur in the UK, the supply chains of chemicals would need to be reconfigured, since most cell production and chemicals supply is currently in Asia. Whilst such components could be imported, to capture the most value cell production and the related chemical and process equipment supply would need to come from UK suppliers.”

RESOLVE prototypes shape future of electric urban commuting

The future of daily urban commuting could be small, lightweight Electric L-category Vehicles (ELVs). A cost effective, energy efficient and comfortable alternative to traditional cars in cities, is at the heart of the €6.92m RESOLVE project, which included WMG at the University of Warwick.

The future of daily urban commuting could be small, lightweight Electric L-category Vehicles (ELVs). A cost effective, energy efficient and comfortable alternative to traditional cars in cities, is at the heart of the €6.92m RESOLVE project, which included WMG at the University of Warwick.

The European project – named ‘Range of Electric Solutions for L-category Vehicles’ – designed and developed two stylish tilting four-wheeler prototype ELVs with leading European manufacturers Piaggio and KTM. These demonstrators were unveiled, and presented to representatives from the European Commission, at an event in Brussels in April 2018.

WMG was one of fourteen partners in the project, which included leading names from industry and research such as Piaggio, KTM, Bosch, Ricardo, the Austrian Institute of Technology, and the University of Florence.

£5.6m Vehicle-2-Grid project develops charging technology in real world

Electric vehicle charging infrastructure on UK roads is to be advanced, thanks to a new £5.6 million project – funded by Innovate UK – to develop Vehicle-2-Grid (V2G)Link opens in a new window technologies, involving WMG at the University of Warwick.

For three years from April 2018, the EV-elocity consortium will conduct a project to demonstrate and develop V2G technology across a variety of UK locations, including airports and business parks – with the aim of proving its viability and worth to business and the wider public.

Researchers at WMG, led by vehicle electrification and energy storage expert Dr James Marco, will build a techno-economic model of how V2G will be viable within the UK. A key innovation will be the inclusion of new models of battery degradation within the analysis that will underpin new methods to optimise the vehicle’s battery system.

Researchers at WMG, led by vehicle electrification and energy storage expert Dr James Marco, will build a techno-economic model of how V2G will be viable within the UK. A key innovation will be the inclusion of new models of battery degradation within the analysis that will underpin new methods to optimise the vehicle’s battery system.

Dr Marco’s team will also analyse real-world usage data from a range of different electric fleet vehicles as they are used within a V2G context.

The project will break new ground in helping consumers, businesses and infrastructure providers to financially benefit from adapting their charging behaviour and vehicle use.

In doing so, the project will help to further accelerate and incentivise the transition from traditional fuel sources to electric vehicles.

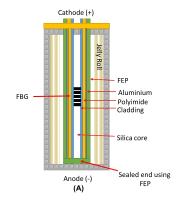

New sensor tech for commercial Lithium-ion batteries finds they can be charged 5 times faster

Researchers at WMG at the University of Warwick have developed a new direct, precise test of Lithium-ion batteries’ internal temperatures and their electrodes potentials and found that the batteries can be safely charged up to five times faster than the current recommended charging limits. The new technology works in-situ during a battery’s normal operation without impeding its performance and it has been tested on standard commercially available batteries. Such new technology will enable advances in battery materials science, flexible battery charging rates, thermal and electrical engineering of new battery materials/technology and it has the potential to help the design of energy storage systems for high performance applications such as motor racing and grid balancing.

Researchers at WMG at the University of Warwick have developed a new direct, precise test of Lithium-ion batteries’ internal temperatures and their electrodes potentials and found that the batteries can be safely charged up to five times faster than the current recommended charging limits. The new technology works in-situ during a battery’s normal operation without impeding its performance and it has been tested on standard commercially available batteries. Such new technology will enable advances in battery materials science, flexible battery charging rates, thermal and electrical engineering of new battery materials/technology and it has the potential to help the design of energy storage systems for high performance applications such as motor racing and grid balancing.

If a battery becomes over heated it risks severe damage particularly to its electrolyte and can even lead to dangerous situations where the electrolyte breaks down to form gases than are both flammable and cause significant pressure build up. Overcharging of the anode can lead to so much Lithium electroplating that it forms metallic dendrites and eventually pierce the separator causing an internal short circuit with the cathode and subsequent catastrophic failure.

Adding graphene girders to silicon electrodes could double the life of lithium batteries

New research led by WMG, at the University of Warwick has found an effective approach to replacing graphite in the anodes of lithium-ion batteries using silicon, by reinforcing the anode’s structure with graphene girders. This could more than double the life of rechargeable lithium-ion based batteries by greatly extending the operating lifetime of the electrode, and also increase the capacity delivered by those batteries.

Revolutionary method reveals impact of short circuits on battery safety

How lithium-ionLink opens in a new window (Li-ion) batteries behave under short-circuit conditions can now be examined, using a new approach to help improve reliability and safety - developed by an international research team, including WMG at the University of Warwick.

How lithium-ionLink opens in a new window (Li-ion) batteries behave under short-circuit conditions can now be examined, using a new approach to help improve reliability and safety - developed by an international research team, including WMG at the University of Warwick.

The use of high energy density Li-ion batteries is ubiquitous – from powering portable electronics to providing grid-scale storage – but defects can lead to overheating and explosions.

Although catastrophic failure is extremely rare, recent high-profile cases including the recall of Samsung’s Galaxy Note 7 smartphone line and the grounding of an aircraft fleet highlight why it’s important to understand battery failure.

Romeo Malik, a researcherLink opens in a new window at WMG, explained the experiment:

“As the safety and reliability of batteries is paramount, it is important to know and understand the extreme scenarios of battery failure.

“In this work, we were able to see the initiation of thermal runway and how quickly it escalated to the neighbouring cells in seconds. Being able to observe and capture these rapid failures with high-speed X-ray imaging technique is amazing.”