Objectives

The project ECSASDPE focuses on the staff exchange between the partners of EU and China, and on  the development of the key enabling technologies for novel machining processes and innovative productive equipment for effectively producing satisfactory holes in high precision aircraft assembly. The ultimate goal of ECSASDPE is to establish long-term research collaboration between Europe and China in an emerging field with promising applications in many research areas including aircraft, aerospace, automotive engineering, energy and environmental science.

the development of the key enabling technologies for novel machining processes and innovative productive equipment for effectively producing satisfactory holes in high precision aircraft assembly. The ultimate goal of ECSASDPE is to establish long-term research collaboration between Europe and China in an emerging field with promising applications in many research areas including aircraft, aerospace, automotive engineering, energy and environmental science.

The objectives of the project are given as follows:

• Establish a long-term research cooperation platform through the ECSASDPE joint programme by exchange of researchers for short periods during the project. At least three new research proposals for both the EU and Chinese funding programmes will be prepared, and visits between partners will be arranged during and after the project period. As the research work is fully supported by partners’ existing projects and their own resources, in such a case, a long-term research cooperation platform ECSASDPE will be firmly established, and will be in function even after the project period.

• Exchange ideas and technology concepts for further development of novel machining processes and innovative productive equipment for effectively and automatically producing satisfactory holes on AL/CFRP/Ti stacks. All the consortium partners have been actively working on international, national and regional research projects in robotics and automation, composite material machining, surface integrity for many years. The advanced knowledge and expertise will contribute to the development of new technologies on ECSASDPE.

• Strengthen research partnerships through staff exchanges and networking activities between European research organisations and Chinese institutions. Partners can learn from each other the new science and technology developments of orbital drilling technique and equipment technologies and benchmark them against their own developments. Each partner will have at least one publication on average each year, giving more than 32 joint publications in total. The consortium targets at least 3 patent applications during the project period.

• Take a synergistic approach to the research areas and explore novel methodologies and applications for potential major scientific and technological breakthroughs by optimal combination of the different backgrounds and disciplines from the partners.

The technology oriented objectives are:

• Exploration of intrinsic mechanisms and relationships between orbital drilling process parameters and geometrical accuracy, mechanical properties as well as surface integrity of holes in AL/CFRP/Ti stacked composites, the crucial fundamentals leading to realization of optimized machining processes.

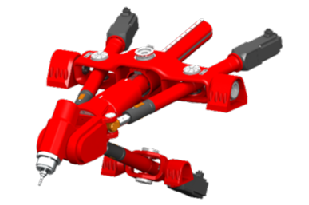

• Development of a theoretical and technical package having phases of conceptual design, kinematic/structural parameter optimization, kinematic calibration, gravity compensation, stiffness-based control, and process monitoring and adaptive tuning necessary to support a set of comprehensive performance and functionality of a novel drilling robot to be realized for drilling and/or helical milling high quality holes in AL/CFRP/Ti stacks.

• Build a prototype as a test bench to validate the abovementioned enabling technologies through a number of tests including drilling of real-life aero-structures.