Lithography

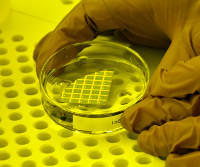

Within the cleanroom is a 40 m2 lithography area, illuminated with yellow light to enable the use of photoresist. Positive and negative photoresists are used in the laboratory, which is also equipped for bi-level resist processes.

Coating

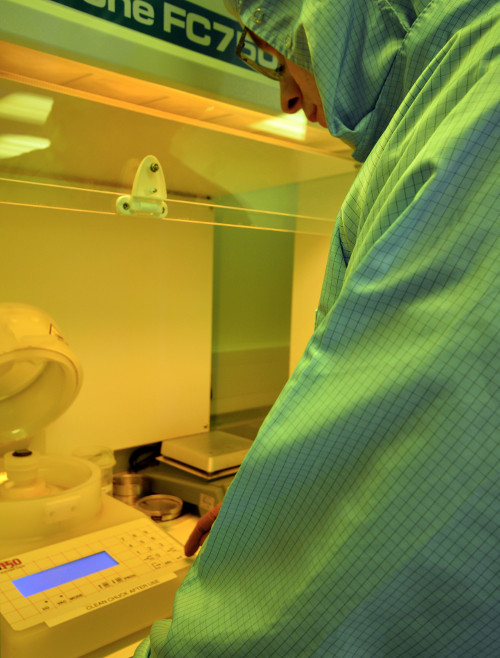

- Spin 150 manual resist spin coater. Supports 0.5 cm square to 6" diameter substrates.

- Laurell WS-650Mz auto dispense spin coater. Supports 2-6" diameter substrates.

Exposure

- Suss Microtec MJB3 manual mask aligner. Supports 0.5cm square to 3" diameter substrates with a 1.5 µm resolution.

- Suss Microtec MA/BA8 mask aligner with SCIL (surface conformal imprint lithography) adaptation. Supports 1cm square to 8" diameter substrates with a 0.75 µm resolution.

- SCIL processing on 2" and 3" diameter substrates to define features down to 50nm.

Develop

- Manual glassware development for small and irregular substrates.

- Laurell EDC-650Hz spin developer for 2-3" diameter substrates.