Sensors

A key area of activities of the BSL group is in the development of gas/chemical sensors. The majority of this work has been in the development of commercial gas sensors, with successes with companies including AMS. Our group have expertise in a number of different gas and chemical sensor technologies - covering both chemical interactions projects as well and physical measurements. We also have extensive gas testing capabilities to characterise gas sensors in controlled environments. Below is some examples of these approaches.

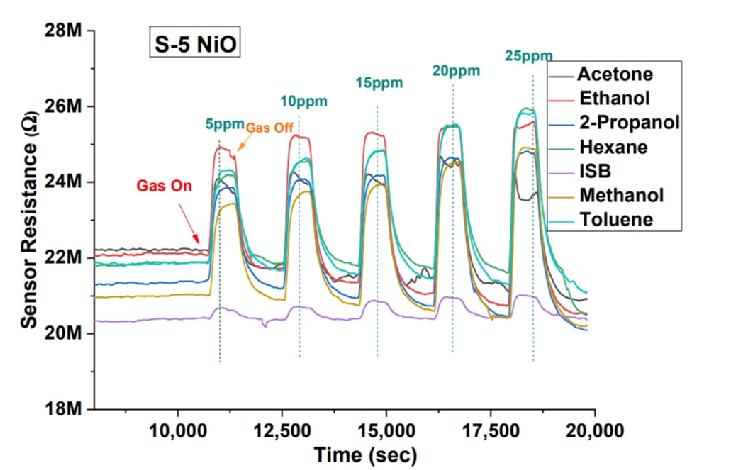

Metal-Oxide Sensor Development

Our group have the ability to design, develop and manufacture both thin film and thick film metal-oxide based gas sensors. We have material development and screen printing capabilities to produce different types of sensors (as shown below). This is an example of a p-type NiO thick film sensor for broad VOC detection. The sensors shows a high sensitivity, with almost zero humidity dependence.

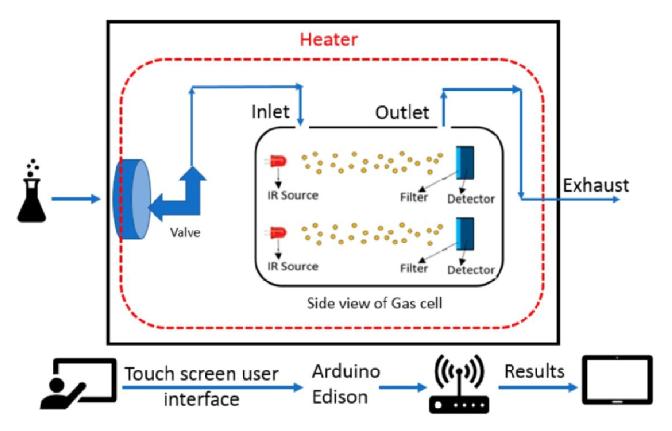

Optical Gas Analysis System

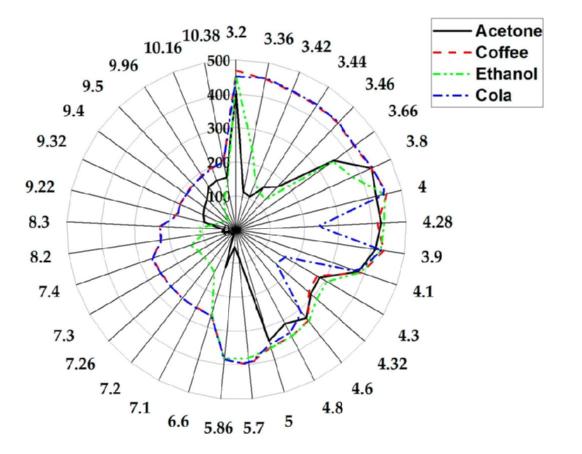

We have also developed gas systems based on optical absorbance. Here we used frequency scanning NDIR to create an array of "virtual sensors" that can be used as an electronic nose configuration. As infra-red light is shone through a cloud of sample, the absorbance of wavelengths can be used to provide information on the chemicals within the cloud. We have used this systems with a range of sample media. The images below give an overview of this system and a radar plot of the instruments output to a few common sample types.

Photo-ionisation Gas Sensor

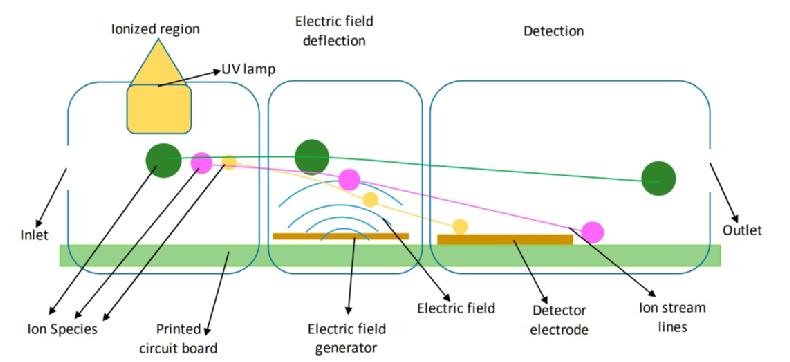

Photoionization detectors (PID) are highly sensitive chemical sensors that are used extensively for

the detection of volatile organic compounds (VOCs). They can provide a linear output to a single

chemical or mix of chemicals, in real-time, and have a sensitivity in the ppb (parts per billion) range

[1,2]. Their ability to analyse samples in ambient temperatures and pressures makes them suitable for

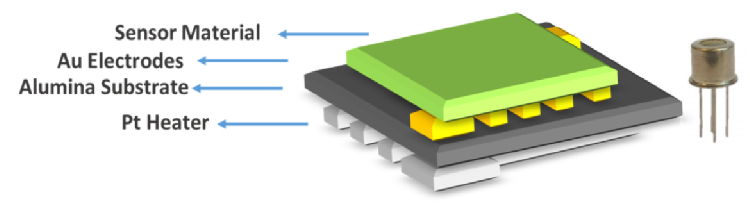

testing in a range of environments and has resulted in their increased use for in situ analysis. However, these sensors only provide a concentration value of the sample being tested, without any additional information of the chemical composition. Additionally, these sensors are not leak proof and cannot be easily used for inline analysis of toxic compounds. Our work in this area is to develop low-cost PID technologies to increase the discriminatory information provided by this sensor. We have developed a planar PID technology to achieve this. This concept is shown in the figure below.

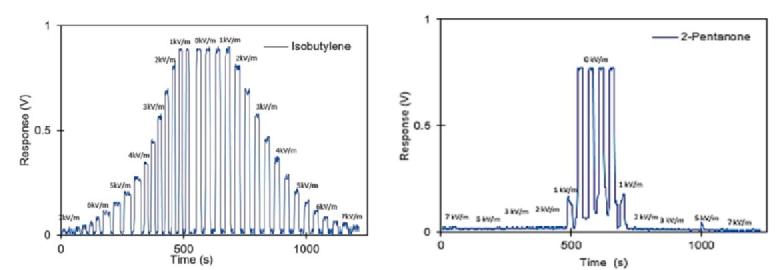

By modulating the electric field on the centre plate, we are able create specific patterns associated with different chemicals. An example of this is shown in the image below.