HetSys Research Themes

Examples of areas of current research within the remit of the HetSys CDT include the following themes. Our Project Opportunities page will show our available projects currently being advertised. This is currently offline as we update availability and a link will appear here when projects become available for our next entry point of Autumn 2022.

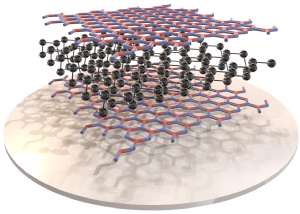

Novel electronic devices. The development of new advanced concepts for devices and materials such as transistors, sensors, thermoelectrics, batteries and photovoltaics requires detailed insight of electronic and thermal properties, degradation processes, stability, manufacturability, etc. Atomic-scale insight into both structure and dynamics is required for material properties and especially for the heterogeneous and often disordered interfaces encountered in realistic material/device environments (resulting from e.g. combining different materials, morphologies, granularities, and structures with different intrinsic scales). Modelling to generate this insight will provide predictions with quantifiable accuracy of properties such as: i) electronic and vibrational spectroscopy, elasticity, ii) accurate electronic/thermal/mass transport description over multiple timescales; iii) efficient multi-scale, multi-physics methods that can accurately capture both the heterogeneous complexities encountered within the materials that form the device, but also how the devices finally form modules. Such knowledge finally feeds into high-level properties e.g. product lifetimes and environmental stability.

Novel electronic devices. The development of new advanced concepts for devices and materials such as transistors, sensors, thermoelectrics, batteries and photovoltaics requires detailed insight of electronic and thermal properties, degradation processes, stability, manufacturability, etc. Atomic-scale insight into both structure and dynamics is required for material properties and especially for the heterogeneous and often disordered interfaces encountered in realistic material/device environments (resulting from e.g. combining different materials, morphologies, granularities, and structures with different intrinsic scales). Modelling to generate this insight will provide predictions with quantifiable accuracy of properties such as: i) electronic and vibrational spectroscopy, elasticity, ii) accurate electronic/thermal/mass transport description over multiple timescales; iii) efficient multi-scale, multi-physics methods that can accurately capture both the heterogeneous complexities encountered within the materials that form the device, but also how the devices finally form modules. Such knowledge finally feeds into high-level properties e.g. product lifetimes and environmental stability.

Catalysis across scales. Catalysis drives the global chemical industry, helping to scrub pollution from our atmosphere, enable atom-efficient synthesis of new drugs and driving more efficient use of existing fossil fuel resources and is used in around 90% of all industrial chemical processes. Yet understanding how a given catalytic complex, solid surface or nanoparticle functions, and can be improved, stands as a clear multi-scale challenge. At the microscopic scale, the reaction barrier and rate of the individual chemical reactions in a catalytic pipeline depend on the molecular-level electronic structure of reactants, and can be computed with controlled uncertainty, yet the observed catalytic turnover frequency is the emergent consequence of many possible such reactions, as well as macroscopic operating conditions such as temperature, pressure and solvent. Propagation of uncertainty across the scales will be key to enable development of heterogeneous modelling to improve catalyst efficiency or selectivity, and is thus paramount to complementing the UK’s existing expertise in synthetic catalysis.

High-performance alloys. The performance of superalloy turbine blades, for example, is controlled by processes coupling electronic structure (physics/chemistry) through microstructure (materials science/engineering) and up to manufactured components, with corresponding uncertainties in alloy composition, microstructure and mechanical properties. Linking heterogeneous models with uncertainty quantification (UQ) would allow alloy performance to be improved so that jet engines can be operated at higher temperatures, increasing their efficiency. The development of interdisciplinary computational tools to address the complexity of heterogeneous materials as well as the reliable quantification of uncertainties is one of the key challenges for next-generation computational materials design. Modelling heterogeneous alloys is challenging because microstructure, internal defects and interfaces are decisive for mechanical properties, but are too large to be modelled with Density Functional Theory (DFT). Most current research applies force-field based methods with severe limitations in accuracy and transferability which need quantifying. HetSys students will be equipped to meet these challenges, and to address a broad range of applications.

Direct-drive laser fusion. Laser-driven fusion systems aim to compress a sphere of deuterium-tritium (DT) to ~1000 times solid density and heat it to 108 K in a few nanoseconds. If this can be achieved it will form the basis of inertial fusion energy – an energy source capable of supplying all the world’s energy needs without CO2 production. Optimising the DT pellets and laser-profiles for direct-drive fusion requires coupling kinetic codes for fast-electron generation, Arbitrary-Lagrangian-Eulerian (ALE) codes for the hydrodynamics and DFT calculations of equations of state and alpha-heating. On top of this the combined hydro-kinetics code needs to generate synthetic diagnostics to allow UQ to constrain the fast-electron distribution from laser-plasma interaction, multi-material mixing and burn physics. The ultimate goal is to optimise the materials, dimensions and smoothness of the pellets and the laser-drive profile and focus characteristics to move laser-fusion forward from experiment to power generation.

Heterogeneous modelling for future medicines. Development and delivery of new pharmaceuticals and formulations to fight contemporary challenges such as improved cancer treatment, neurodegenerative diseases and emerging antibiotic resistance demands a multi-scale and multi-methodology approach. For example, machine-learning can be employed to identify new therapeutically useful or lead compounds by mining existing experimental databases or large repositories of computed data. The basis of biological action of these leads can be identified using molecular dynamics on picosecond time-scales, while drug transport across lipid cell membranes can be modelled over microsecond time-scales using coarse-graining calculations although to date quantified uncertainties are missing. As free energy and microkinetic modelling push further into the time-domain, the impact of processing conditions on polymorph control, solubility and dispersity can be predicted with a view to effective formulation and delivery.

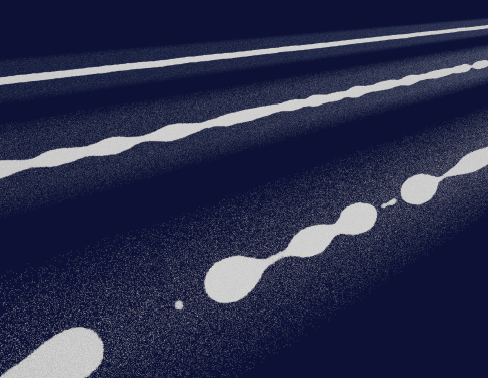

Smart nanofluidic interfaces. To enable emerging nanofluidic technologies to realise their potential requires heterogeneous multiscale modelling techniques that connect unique nanoscale features to new engineering-scale capabilities For example, the complex dynamics of evaporating sprayed microdrops impacting engineered surfaces must be understood in order to unlock the potential of high-power electronic devices (e.g. power amplifiers, internet routers, etc) whose performance is currently limited by thermal management constraints. The nanoscale physics associated with this flow, such as the Leidenfrost effect which suspends microdrops on an evaporated vapour nano-film, directly determines the efficiency of heat removal and yet is completely ignored by classical engineering software, partly because errors arising when upscaling have not yet been systematically accounted for. Only with interdisciplinary training in multiscale modelling and uncertainty quantification and the expertise of international and industrial partners can students surpass classical modelling in order to design new disruptive technologies.

Composite materials with enhanced functionality. New computational methods are needed to aid development and optimisation of next-generation composite materials based on polymer and ceramic matrices with nano- to micro-size particles. Those methods require computationally efficient scale-bridging concepts such as nonlinear homogenisation to span nano to macro spatial scales. Also, nonlinear constitutive models describing heterogeneous material response under the action of different stimuli (mechanical, electrical, chemical) are required. These models must undergo a robust implementation into multiscale methods with the uncertainties in constituent properties, manufacturing-induced microstructure and microscopic damage mechanisms quantified to produce reliable predictions of composite properties with error bars using widely used codes.

Heterogeneity of underground systems. Finding ways to protect environmentally threatened groundwater resources and to design strategies for the safe exploration and extraction of fossil fuel resources from underground reservoirs (i.e. ‘fracking’) both require understanding of the hydro-chemo-mechanical (HCM) processes present in heterogeneous media which differ greatly from those for homogeneous media. For example, heterogeneity enhances solute/gas mixing via its influence on the dispersion and segregation of dissolved substances, requiring atomic scale modelling. It also affects fluid-rock interactions at the microscale in fractured underground reservoirs. With high quality experimental data on the spatial and temporal variation of the properties of such heterogeneous systems now being available, we can transform understanding of HCM processes by incorporating information from DFT (e.g. chemisorption of reactive molecules driving stress corrosion cracking) and atomistic calculations (e.g. effects of inhomogeneities on wave propagation speeds) into improved continuum models that produce predictions along with quantified uncertainties.

Mathematical challenges. A significant proportion of the research topics will be based on sophisticated mathematical techniques for modelling and simulation, including but not limited to aspects of numerical analysis (optimised numerical algorithms, approximation theory), nonlinear partial differential equations, inverse problems (optimisation of model parameters, system specific regularisation), extending the underlying mathematical methodology used for uncertainty quantification (accounting for statistical fluctuations of model discrepancy e.g. by considering suitable microscale models) and coarse-graining (multi-scale analysis to account for a multitude of temporal and spatial scales). There is a substantial research community focused on these topics within the wider field of applied and computational mathematics, continuously producing significant new developments. The Warwick Mathematics Institute, with a long tradition in these fields, is well-placed and committed to supporting the advancement of theoretical underpinnings of the new models and algorithms developed in this CDT.

Simulation optimisation. When combining computational models with optimisation tools it becomes possible to search large spaces of potential designs, enhancing innovation capabilities. Simulation-based optimisation faces challenges when used with multiscale models and in the presence of uncertainty. Optimisation engines have the choice of using multi-fidelity models, with a trade-off between the number of designs and evaluation accuracy. Research on multi-fidelity optimisation is still in its infancy and many challenges remain, e.g. to include uncertainty in model parameters or to extend to multi-objective optimisation. UQ has mostly been used in combination with deterministic models to date; we will extend to stochastic systems, e.g. heterogeneous microstructure and manufacturing variability.