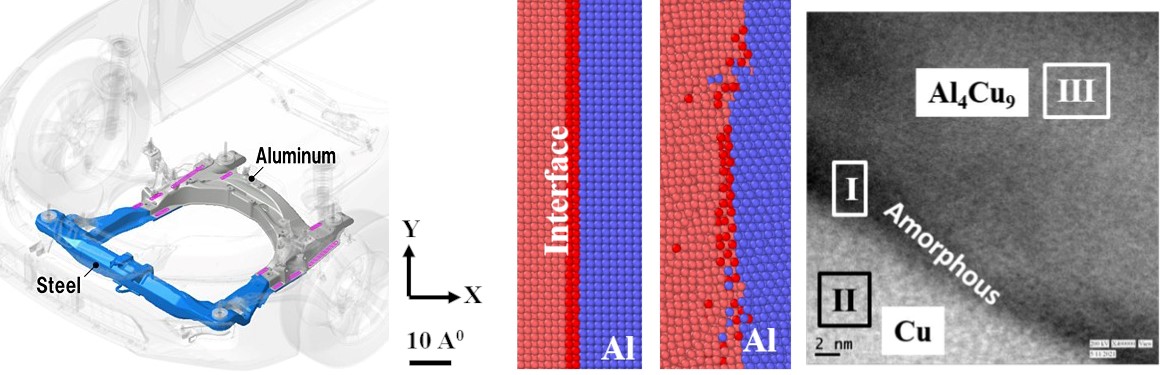

Aluminium-steel laser welding: What happens at the interface?

Left: Automotive frame with steel and aluminium parts welded together. Centre: Interface between aluminium and copper in an atomistic simulation before and during weld process. Right: Transmission electron microscopy image of interface between copper and a copper-aluminium intermetallic compound [1]. The Cu/Al interface is used for illustrative purposes as a stand-in for the Fe/Al interface.

Project supervisors: Peter Brommer; Prakash Srirangam

Summary: Aluminium and steel are widely employed metallic materials for automotive applications, such as in vehicle frames. Joining of these two dissimilar metals by laser welding results in formation of brittle aluminium-iron intermetallic compounds at the interface, which degrade the performance of the weld. Here, you will study the joining process through simulations on an atomic scale, directly exploring how iron and aluminium atoms move into the opposite material during and after laser irradiation, supported by transmission electron microscopy analysis. The aim is to find favourable laser weld conditions to mitigate the formation of brittle intermetallics in this technologically relevant process.

Background: Aluminium and steel are widely employed metallic materials for automotive applications, such as in vehicle frames. Joining of these two dissimilar metals by laser welding results in formation of brittle aluminium-iron intermetallic compounds at the interface, which degrade the performance of the weld. Here, you will study the joining process through simulations on an atomic scale, directly exploring how iron and aluminium atoms move into the opposite material during and after laser irradiation, supported by transmission electron microscopy analysis. The aim is to find favourable laser weld conditions to mitigate the formation of brittle intermetallics in this technologically relevant process.

The project is focused on understanding the interaction between Fe and Al atoms at the weld interface during laser welding of steel to Al alloy. You will employ atomistic modelling techniques, particularly molecular dynamics (MD) and Kinetic Monte Carlo (KMC) to study atomic motion during and after laser irradiation, as well as the mechanical properties of the weld. The effect of weld parameters on interfacial properties, vacancies and dislocations via mutual diffusion of Fe and Al will be experimentally supported with TEM microscopy analysis performed by an India-based PhD student supervised by Prakash Srirangam.

A better understanding of the formation of brittle intermetallic compounds during laser welding of dissimilar steel to Al would not only lead to improved mechanical properties of weld joints, but also help to achieve net zero emissions with usage of light-weight materials for engineering applications.

[1] Omkar Mypati, Polkampally Pavan Kumar, Perwej Iqbal Md, Surjya Kanta Pal & Prakash Srirangam (2021) Molecular dynamics simulation of atomic diffusion in friction stir spot welded Al to Cu joints, Mechanics of Advanced Materials and Structures, DOI: 10.1080/15376494.2021.1972188

Are you interesting in applying for this project? Head over to our Study with Us page for information on the application process, funding, and the HetSys training programme

At the University of Warwick, we strongly value equity, diversity and inclusion, and HetSys will provide a healthy working environment, dedicated to outstanding scientific guidance, mentorship and personal development.

HetSys is proud to be a part of the Physics Department which holds an Athena SWAN Silver award, a national initiative to promote gender equality for all staff and students. The Physics Department is also a Juno Champion, which is an award from the Institute of Physics to recognise our efforts to address the under-representation of women in university physics and to encourage better practice for both women and men.