hp-01-image

The Academic Profile pages use a standard School of Engineering template to give a degree of consistency for all our staff profiles. The template is intended to be easy to use and reasonably flexible. The are some standard content blocks to filled in:

Left hand side

Right hand side

Plus there are four additional blocks available for use on the left hand side and two on the right hand side. The display order of the content blocks cannot be changed.

The content in any block can be updated through the "Edit" button; any blocks that do not contain a minimum amount of content will be hidden on the profile page. Please do not change the Title of any content block as this will break the link to the Profile page.

If these blocks are too restrictive for the content you wish to publish, then you have Edit permission for your own profile and can create any number of standard Sitebuilder sub-pages. Just make sure not to create the sub-pages beneath this "hp-content" page -- create them below your main profile page so that they can be seen in the menu.

Professor of Materials Modelling

J dot R dot Kermode at warwick dot ac dot uk

+44 (0) 24 7652 8614

I am Professor of Materials Modelling in the School of Engineering at the University of Warwick, where I am also currently serving as Research Cluster Leader for the Predictive Modelling research cluster. I also direct the EPSRC Centre for Doctoral Training in Modelling of Heterogeneous Systems (HetSys) and the Warwick Centre for Predictive Modelling (WCPM) university research centre.

D210

Book a slot for a 15 minute appointment, either in person or online.

School of Engineering, University of Warwick, Coventry, CV4 7AL

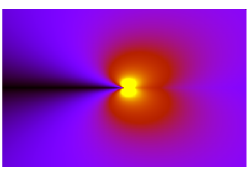

I develop multiscale materials modelling algorithms and the software that implements them, with a particular focus on machine learning and data-driven approaches, and on quantifying the uncertainty in the output of electronic structure and atomistic models. I am also active in applying parameter-free modelling techniques to make quantitative predictions of "chemomechanical" materials failure processes where stress and chemistry are tightly coupled, e.g. near the tip of a propagating crack (left), where local bond-breaking chemistry is driven by long-range stress fields. Prominent examples include:

I develop multiscale materials modelling algorithms and the software that implements them, with a particular focus on machine learning and data-driven approaches, and on quantifying the uncertainty in the output of electronic structure and atomistic models. I am also active in applying parameter-free modelling techniques to make quantitative predictions of "chemomechanical" materials failure processes where stress and chemistry are tightly coupled, e.g. near the tip of a propagating crack (left), where local bond-breaking chemistry is driven by long-range stress fields. Prominent examples include:

|

|

In 2025/26 I will be teaching PX914 - Predictive Modelling and Uncertainty Quantification in the HetSys CDT and ES98E - Scientific Machine Learning in the MSc in Predictive Modelling and Scientific Computing.

See also my full Publications page, my Talks page, and my profiles on ORCID, Google Scholar and the Warwick Research Archive Portal. My PhD Thesis is available from the University of Cambridge's repository.

PI for Royce Institute Materials Challenge Accelerator Programme Hydrogen diffusion and trapping in multi-principal component alloys. Co-Is J. Darby (PDRA), R. Maurer and A. Bartok-Partay

No vacancies at present. HetSys CDT PhD projects for Oct 26 start will be advertised in late autumn 2025.