Manufacturing Process

|

|

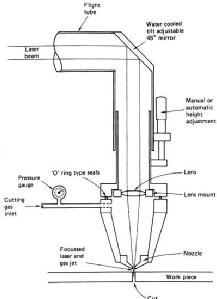

Your toy is laser cut

At the School of Engineering build space, you have access to a range of manufacturing tools and support such as 3D printers and laser cutters.

Your toy is produced right here at the School's build space using our state of the art laser cutter.

This page uses content from another page, which no longer contains valid information, or has since been deleted. Please contact the page owner using the link at the bottom of the page if you think this content should be available.