Highlights of our PhD projects currently recruiting

We've highlighted some of our PhD projects currently open for UK applicants below.

HetSys is built around a closely knit, highly collaborative team of academics from five science departments at Warwick with a strong track record in leading large projects.

Click on the supervisors for more details of our wonderful team or visit our people pages to see what our other student cohorts are working on.

To see all of our projects currently recruiting UK applicants click here.

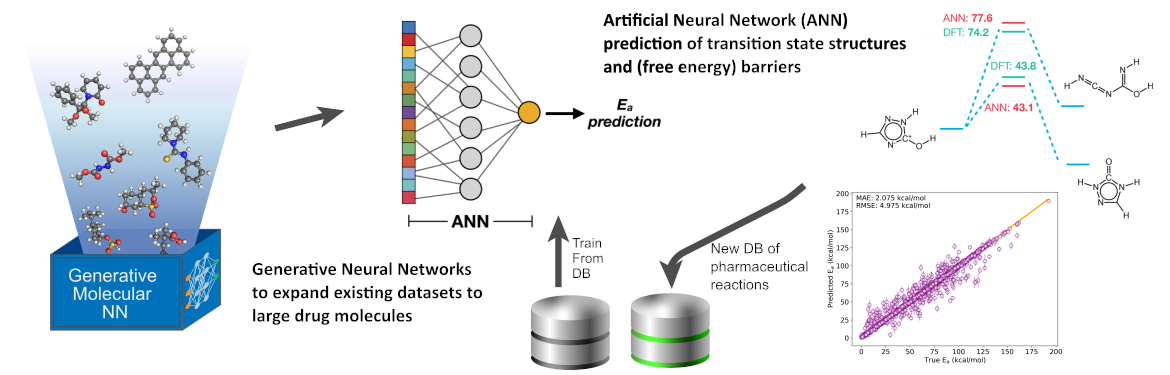

Deep learning of reaction barriers for high-throughput retrosynthetic drug design

The drug discovery pipeline involves the screening of many molecules before viable leads are identified. This involves screening for their pharmacological properties, but also for their synthetic viability. Typical drug molecules can contain up to 100 non-hydrogen atoms, which makes the development of cost-effective and efficient synthetic pathways very challenging. Therefore, high-throughput screening of drug-like molecules needs to also consider their synthetic viability. The aim of this project is to develop a deep learning and generative design toolchain to accurately predict chemical reaction barriers that will advance chemical retrosynthetic design workflows. The project is in collaboration with a leading pharmaceutical company and will involve an extended industrial placement

Supervisors

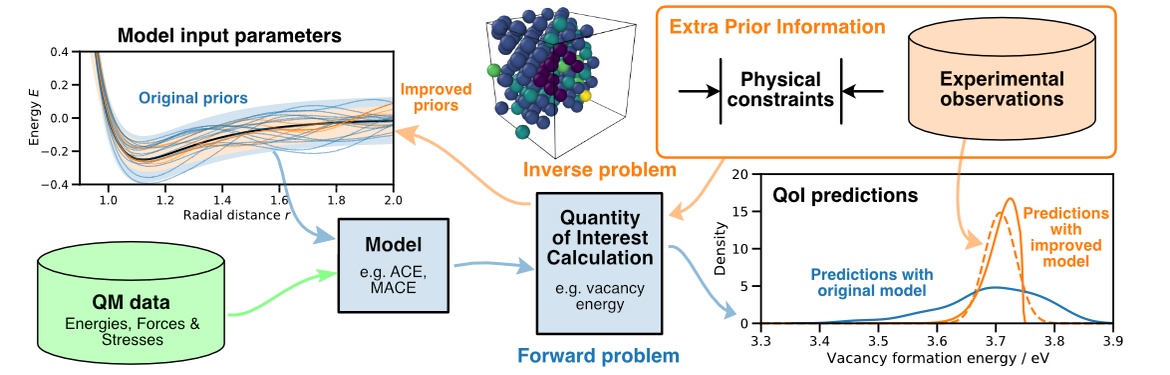

Better-conditioned Inverse Problems in Computational Materials Science

Inverse problems are a general class of problems that involve calibrating the parameters of a model using measurements of its outputs, typically from real-world experiments. Many such problems occur across computational science, e.g. in the calibration of constitutive parameters such as elastic moduli (and other examples below) on the basis of computational simulations. However, these problems are often mathematically ill-posed, meaning there is no single, stable, well-defined solution. This issue may be resolved numerically either using classical optimisation approaches which select a single solution (that may be an artefact of the choice of optimizer) or using tools from statistics and machine learning such as Bayesian inference which mitigate the ill-conditioning of the problem by incorporating prior information.

Building better batteries: modelling and optimisation of electrode filling

Manufacturing not only has a significant impact on battery performance and lifetime, but also on cost and environmental impact. A key process (yet not a well-studied one) is the so-called filling, in which a liquid electrolyte is incorporated into the battery, occupying the pores in the electrodes. It requires keeping the battery at high temperatures for days, becoming a very expensive process both in terms of time and energy usage. In this project, you will have the opportunity to build exciting new capabilities for modelling and optimisation of electrode filling, with a potential to energise our understanding of battery manufacturing.

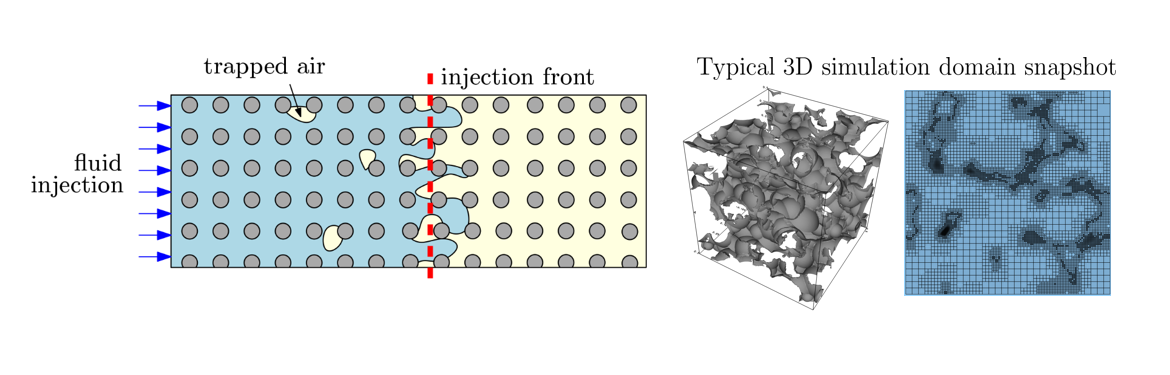

Hybrid modelling approaches for moving fluid-fluid interfaces around solid obstacles

Interfacial fluid flows around obstacles and through porous materials are key to numerous applications, including filtration, decontamination and manufacturing. For instance, resin must be injected into a porous mesh, without trapping air bubbles, to manufacture composite materials. Interfacial flows are difficult to model and simulate accurately, and in porous media the multiple disparate lengthscales further complicates matters. However, this multi-scale setting also provides beautiful mathematical modelling opportunities. In this project we will develop and use hybrid modelling approaches for moving fluid-fluid interfaces around obstacles, incorporating analytical and computational techniques, to investigate questions such as minimising defects in composite manufacturing.