Departmental news

New research says Sodium-ion batteries are a valid alternative to Lithium-ion batteries

- Lithium (Li)-ion batteries (LIBs) are the electrochemical energy storage systems of choice for a wide variety of applications, however other types of emerging battery technologies are currently on the path to share their dominant position.

- Among them Sodium (Na)-ion batteries (NIBs) have great potential to represent the next generation low cost and environmentally friendly energy storage solution. The diverse key performance indicators required by different applications and the market diversification is the driving force pushing the Na-ion technology closer to the market.

- A team of scientists including WMG at the University of Warwick combined their knowledge and expertise to assess the current status of the Na-ion technology from materials to cell development, offering a realistic comparison of the key performance indicators for NBs and LIBs.

LIBs play a primary role in the transition to a low carbon economy. However, as the market rapidly expands, the environmental and social challenges associated with the mass production of LIBs is triggering large attention toward the search for alternative energy storage solutions based on materials that can be sourced in a sustainable and responsible way. In this scenario, NIBs represent an alternative low cost, sustainable and more environmentally friendly energy storage technology.

LIBs play a primary role in the transition to a low carbon economy. However, as the market rapidly expands, the environmental and social challenges associated with the mass production of LIBs is triggering large attention toward the search for alternative energy storage solutions based on materials that can be sourced in a sustainable and responsible way. In this scenario, NIBs represent an alternative low cost, sustainable and more environmentally friendly energy storage technology.

In the paper ‘Challenges of today for Na-based batteries of the future: from materials to cell metrics,' published on the 18th of September 2020 in the Journal of Power Sources, a large team of Na-ion technology expert scientists, led by WMG, at the University of Warwick (UK) analyse the prospect of NIBs taking a spot in the energy storage market. The paper also includes researchers from: Helmholtz Institute Ulm (Germany), College de France (France), Humboldt University Berlin (Germany), Institute for Energy technology (Norway), Université de Picardie Jules Verne (France), University of Bordeaux (France) and CIC energiGUNE (Spain).

Na- based batteries offer a combination of attractive properties. They are low cost, use sustainable precursors and have secure raw material supplies. In addition, they are considered as a drop-in technology which could benefit from the already existing Li-ion batteries manufacturing facilities.

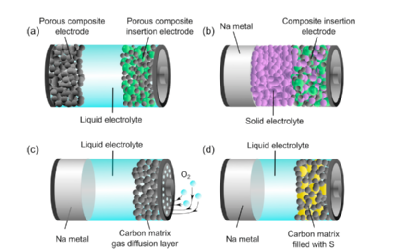

As Li-based systems, Na-based batteries come in different forms, such as Na-ion, Na-all-solid-state-batteries, NaO2 and Na/S. While the last ones are seen as disruptive future technologies, the Na-ion technology represent an attractive technology almost ready to challenge the Li-ion batteries in specific applications.

Performance metrics are of utmost importance for the SIB technology to ensure a competitive cost per Wh and find a place in the market. In this work, the most promising electrode materials and electrolyte systems have been reviewed and performance metrics from the academic literature have been used to extrapolate full sodium ion cells performance indicators.

Authors indicate that with the ongoing development, the present best materials available for Na-ion cells should allow approaching the energy density of the present generation of Li-ion commercial cells. One of the most important application field for the developed sodium-ion battery prototypes is certainly stationary energy storage systems, where cost and cycle life represent two fundamental parameters. “In this field sodium-ion batteries have the potential to dominate the future market representing the most promising system to fill the gap between energy production and utilization by securing energy supply. However high-power applications in the electrified automotive field are a potential niche field application for NIBs” says Dr Ivana Hasa, Assistant Professor at WMG.

Further technological improvements are needed to increase the performance especially in terms of energy density. Extremely encouraging results have been achieved for the Na-ion technology in a very short time when compared to the Li-ion technology. Technological improvement will be achieved by cell component fabrication/assembly optimization, as occurred in the last thirty years for the LIB technology.

Dr Ivana Hasa, from WMG, University of Warwick comments:

Dr Ivana Hasa, from WMG, University of Warwick comments:

“From an applied research point of view, the future research efforts should be devoted on fundamental research, materials discovery and understanding of the thermodynamic and kinetic processes governing the chemistry of these systems. In addition, the investigation of upscaled Na-ion batteries is of primary importance to obtain realistic data to benchmark the progress of the technology as well as the adoption of a common reporting methodology in the scientific community enabling a fair comparison among performance results.”

Battery life for wearable electronic devices could be improved with design considerations to stress asymmetry clues in cylindrical battery cell formats

Researchers in WMG and the Department of Physics at the University of Warwick have found that asymmetric stresses within electrodes used in certain wearable electronic devices provides an important clue as to how to improve the durability and lifespan of these batteries.

Batteries for medical applications and wearable devices continue to evolve in size and shape, with miniaturisation of Li-ion technologies becoming increasingly popular. However, as the size of the battery shrinks, the fabrication process for composite electrodes and the use of liquid electrolyte is becoming a processing challenge for microfabrication using conventional approaches.

Lithium cobalt oxide LiCoO2 (LCO) has remained a common choice of cathode for these small formats due to its high voltage platform and energy density. However, following the initial reported performance benefits of LCO, it is known that LCO cells have large impedance issues due to the growth of high surface layer resistance and charge transfer resistance. This can affect how efficiently the battery charges and discharges. There are also ethical and health considerations around the use of the element cobalt. The increasing impedance was thought to be attributable to the growth of a surface layer on both the anode (solid electrolyte interface, SEI) and cathode (cathode electrolyte interface, CEI) due to the reaction between the electrodes and the electrolyte.

Lithium cobalt oxide LiCoO2 (LCO) has remained a common choice of cathode for these small formats due to its high voltage platform and energy density. However, following the initial reported performance benefits of LCO, it is known that LCO cells have large impedance issues due to the growth of high surface layer resistance and charge transfer resistance. This can affect how efficiently the battery charges and discharges. There are also ethical and health considerations around the use of the element cobalt. The increasing impedance was thought to be attributable to the growth of a surface layer on both the anode (solid electrolyte interface, SEI) and cathode (cathode electrolyte interface, CEI) due to the reaction between the electrodes and the electrolyte.

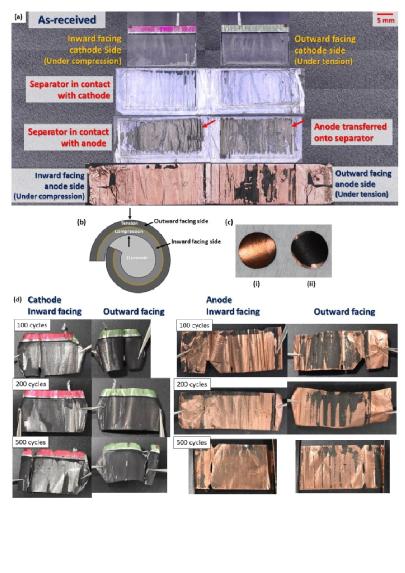

However, in the paper “Ageing analysis and asymmetric stress considerations for small format cylindrical cells for wearable electronic devices” published recently in the Journal of Power Sources, the University of Warwick’s WMG and Physics department researchers disassembled these cells. They have found that and the condition of the cathode and anode varied greatly after 500 cycles, as a function of which side of the current collector it was on.

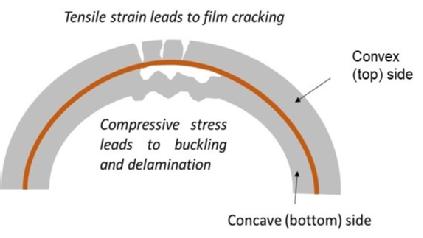

The inward facing cathode (under compression) when rolled into a jelly-roll, develops significant signs of coating delamination from the aluminium foil. On the outward facing cathode side (under tension), however, only a partial delamination was evident and the coating was transferred unto the separator. By contrast, severe delamination was observed on both sides of the anode coating. The inward facing anode side (under compression) showed almost no coating still adherent to the copper foil, compared to the outward facing anode side (under tension). Likewise, the delaminated coating had become adhered to the separator during operation.

outward facing cathode side (under tension), however, only a partial delamination was evident and the coating was transferred unto the separator. By contrast, severe delamination was observed on both sides of the anode coating. The inward facing anode side (under compression) showed almost no coating still adherent to the copper foil, compared to the outward facing anode side (under tension). Likewise, the delaminated coating had become adhered to the separator during operation.

Dr Mel Loveridge from WMG, University of Warwick comments:

“It is interesting to note that, for both the cathode and the anode, the delamination is more severe on the electrode coating side that would have been subjected to compression stress, rather than tensile strain. This can be further explained by considering the asymmetric forces in place on either side of double side coated electrodes.”

The research team also carried out electrochemical testing, X-ray photoelectron spectroscopy (XPS), X-ray computed tomography (XCT) and scanning electron microscopy SEM), to reveal the battery’s structural features and changes. They found that it maintains 82% cell capacity after 500 continuous charging and discharging, after which it shows severe delamination due to high bending stress exerted on the cell components. However this seemingly has minimum impact on the electrochemical performance if the coating is sufficiently compressed in the jelly roll with a good electrical contact. After ageing, the surface layers continue to grow, with more LiF found on the cathode and anode.

Their research opens up exciting areas in battery manufacturing to address winding issues for cylindrical cells (especially miniaturised formats). For example, highlighting the need to understand whether there is merit in varying the coating properties on each side of double-sided coating for wound cylindrical cells, in order to improve the mechanical resilience of coatings that have asymmetric stresses exerted on them.

ENDS

25 AUGUST 2020

NOTES TO EDITORS:

Paper available to view: https://www.sciencedirect.com/science/article/abs/pii/S0378775320309307?via%3Dihub

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/wearable_image.jpg

Caption: An image demonstrating the stresses to anodes and cathodes after cycles.

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/july_2020/mel_l.jpg

Caption: A diagram of how tensile strain leads to the film cracking

Credit: WMG, University of Warwick

The full research team on the paper were:

Ageing analysis and asymmetric stress considerations for small format cylindrical cells for wearable electronic devices C.C. Tan, Marc Walker, Guillaume Remy, Nadia Kourra, Faduma Maddar, Shaun Dixon, Mark Williams and Mel Loveridge.

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

The WMG Battery School is back, and it’s virtual!

The WMG Battery School, supported by the APC and HVM Catapult, will take place, from 14th to 18th September, for key industry personnel.

The WMG Battery School, supported by the APC and HVM Catapult, will take place, from 14th to 18th September, for key industry personnel.

WMG battery experts will facilitate a mix of live lectures and pre-recorded practical hands-on-sessions, virtually, over the five days.

The lectures will cover manufacturing Lithium batteries, module and pack design, electrical testing and ageing, battery management systems, safety and abuse testing, forensic characterisation and battery end of life.

Meanwhile the practical, pre-recorded in the Energy Innovation Centre, lab sessions, will focus on microscopy; electrode mixing and coating; pouch and cylindrical cell fabrication; cell and module testing; and forensics.

Find the full lecture and demo programme and register your interest here or by email: WMGShortCourses@warwick.ac.uk

Charging ahead at Battery School

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG battery experts will facilitate a mix of lectures and practical hands-on-sessions, with the intention of inspiring the next generation of engineers into battery related careers, crucial for the UK’s electrification sector.

The lectures will cover areas including manufacturing Lithium batteries, module and pack design, electrical testing and ageing, battery management systems, safety and abuse testing, forensic characterisation and battery end of life.

Meanwhile the practical lab sessions will focus on microscopy; electrode mixing and coating; pouch and cylindrical cell fabrication; cell and module testing; and forensics.

Find out more and book your place here.

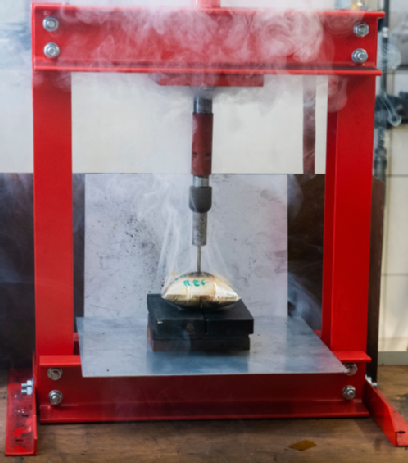

Car batteries can be frozen for safer transportation

Currently transporting damaged and defective car batteries is an expensive process as they need to be placed in an explosion proof box which costs thousands of pounds, however researchers from WMG at the University of Warwick in collaboration with Jaguar Land Rover engineers have been able to freeze batteries with Liquid Nitrogen.

An explosion proof box to transport a typical Tesla sized battery costs €10,000 and a further €10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

€10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

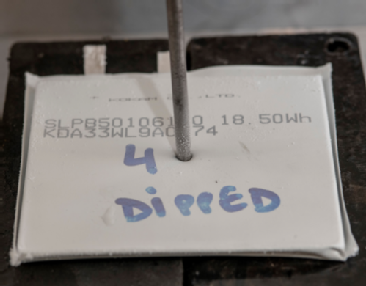

In the paper, ‘Cycle life of lithium ion batteries after flash cryogenic freezing’ published in the Journal of Energy Storage, researchers highlight that cryogenic freezing does not reduce lithium ion battery’s energy capacity or affect cycle or service life, and could be transported in a safer way.

As the sales of electric vehicles increases, there is more concern for the transportation of damaged and defective lithium ion battery packs. Currently, it is an expensive process, as they are put in an explosion proof box that costs €10,000 and a further €10,000 for the UN accreditation, which EV manufacturers are picking up the bill for.

Explosion boxes are used to contain the battery in case it goes into thermal runway, an overheating condition which can lead to violent explosions and toxic gases being released. However being able to cryogenically flash freeze the batteries completely removes the risk of an explosion, and could therefore mean they can be transported safely in a plastic box.

Researchers who were part of the ELEVATE project funded by EPSRC, WMG Centre High Value Manufacturing Catapult, and  supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

When being transported batteries will have to be kept in a lorry at -35 degrees, however the amount of packaging is significantly less than explosion proof boxes, making the process more sustainable.

Dr Thomas Grandjean from WMG, at the University of Warwick comments:

“Transporting damaged and defective batteries is an expensive and unsustainable process, however being able to freeze them with liquid nitrogen could save thousands of pounds and help electric vehicle manufacturers be more sustainable.

“We tested the batteries in the most extreme abuse conditions, such as driving nails through the cells and inducing external short circuits, proving that the freezing process is effective and safe.”

ENDS

2 DECEMBER 2019

NOTES TO EDITORS

High-res images available credit to WMG University of Warwick at:

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_3_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_5_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_7_.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_6.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_2_.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/untitled.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or + 44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Used electric vehicle batteries could be used for rickshaws in Bangladesh

Used EV batteries could be used to power rickshaws in Bangladesh, as researchers from WMG, University of Warwick, seek to find out how they can be repurposed for the rickshaws and lower peoples’ carbon footprint.

Motorised rickshaws, also known as easy-bikes, have gained popularity in Bangladesh due to their cost-effectiveness with one million of them all over the country.

However, the easy-bike currently uses a lead-acid battery for power, which has a lifetime of 6-12 months and therefore increases the operating cost as well as the carbon footprint.

In order to reduce the carbon footprint, researchers at WMG are exploring the possibility of repurposing used EV Li-ion batteries thanks to a £25,000 grant from Global Challenges Research Fund (GCRF), an award from the UKRI aimed to deliver scalable solutions to issues faced by low and middle-income countries.

Currently, Li-ion batteries retire from EVs after reaching 70-80% of their state of health (SoH). At 70% SoH, the lithium-ion battery still have 3 times higher energy density than a new lead-acid battery, and potentially can have a lifetime of 3-5 years in easy-bike application.

The researchers hope to repurpose the batteries to improve the energy storage life from 6-12 months to 3-5 years, which in turn will reduce the number of batteries being recycled and improve the ecosystem.

The new application of Li-ion batteries will be better environmentally without an additional cost in transport. As easy-bike replaces manual driving, the quality of life will improve significantly and bring a socio-economic change to a large community in Bangladesh. Furthermore, this development could reduce the consumption of grid-connected electricity which could be used to develop industries and infrastructure.

In fact, there are currently one million rickshaw pullers in Bangladesh who earn $4.8 billion every year. The new development in easy-bikes will directly improve their economic status. A few million people involved in vehicle support such as mechanics and manufacturing industries will also be benefited.

This project eventually could lead to mass production of second-life Li-ion batteries in Bangladesh, in conjunction with UK automobile industries, which will create job opportunities for thousands of people.

Dr Mohammad Al-Amin from WMG, University of Warwick comments:

Dr Mohammad Al-Amin from WMG, University of Warwick comments:

“To prevent climate change, all cars in the future will need to be electric. However, the batteries in EVs once they have reached their end of life, for car purposes, is something that can be explored more, as there is still energy left in them to be used.”

“If we can re-purpose them to be used for easy-bikes in Bangladesh it will help lower their carbon footprint and provide the country with a new economy. Thousands of jobs opportunities could be created both in Bangladesh and the UK.”

ENDS

13 NOVEMBER 2019

NOTES TO EDITORS

High-res images available at: https://warwick.ac.uk/services/communications/medialibrary/images/october2019/mohammad_photograph.jpg

About GCRF - https://www.ukri.org/research/global-challenges-research-fund/

UK Research and Innovation works in partnership with universities, research organisations, businesses, charities, and government to create the best possible environment for research and innovation to flourish. We aim to maximise the contribution of each of our component parts, working individually and collectively. We work with our many partners to benefit everyone through knowledge, talent and ideas.

Operating across the whole of the UK with a combined budget of more than £7 billion, UK Research and Innovation brings together the seven research councils, Innovate UK and Research England.

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

The future of mobility: Times are changing

Times are changing

If we are to seize electrification and autonomy opportunities, it’s essential that the UK develops an environment suitable for breakthrough technologies. From domestic charging solutions to developing repeatable testing environments, the UK faces big challenges and we are addressing these through our lead centre for Vehicle Electrification and Connected and Autonomous Vehicles at WMG, University of Warwick.

Electrification shaping a low carbon future

David Greenwood – Professor, Advanced Propulsion Systems at WMG, University of Warwick

Demand for electric vehicles (EVs) is surging in the UK and registrations of plug-in cars increased by more than 160,000 between 2013 and 2018. With the electrification industry estimated to be worth over £6billion by 2025, the next decade presents a massive opportunity.

As our society continues to grow, transformation in energy and mobility is required to create sustainable environments. The electrification of transport is shaping that low carbon future. Our vision at WMG is to enable the development of cleaner, safer and smarter vehicles and help drive sustainable mobility across the UK, which aligns with the Government’s ‘Road to Zero’ strategy, aiming to make road transport emission-free by 2050. Our research focuses on establishing advanced hybrid and electrical vehicles, including commercial, rail and marine, battery technology, supply chain, manufacturing and automation.

At WMG, we’re working with the UK Battery Industrialisation Centre to deliver on the UK’s Industrial Strategy ‘Future of Mobility’ Grand Challenge to transform the UK into a world leading battery manufacturer for vehicle electrification.

Connected and Autonomous Vehicles

Siddartha Khastgir – Head of Verification and Validation, Intelligent Vehicles at WMG, University of Warwick

The global Connected and Autonomous Vehicles (CAV) industry is estimated to be worth over £50billion by 2035, with the UK CAV industry comprising over £3billion of this. The UK Government's Industrial Strategy aims to bring fully autonomous cars without a human operator on UK roads by 2021, which will make us one of the first countries to achieve this.

The CAV vision is motivated by the potential societal benefits the technology offers – increasing safety, decreasing traffic congestion and driving lower emissions. At WMG, we’re striving to deliver these through Intelligent Vehicles research exploring Verification and Validation, Communications (i.e. 5G), Experiential Engineering, Supply Chains, Cyber Security and Cooperative Autonomy.

Our involvement in research programmes like the £35m Midlands Future Mobility focuses on “smart miles”, proving concepts and getting products to market. Led by WMG, Midlands Future Mobility is an “on-road ecosystem” comprising nine partners with a shared objective – To launch the first service offering of public road testing by mid-2020.

Times are changing.

‘Nextrode’ project to revolutionise the manufacturing of battery electrodes

· Nextrode project could revolutionise the way electrodes for Li-ion EV batteries are manufactured

· Smart high performance electrodes could enable EVs to travel further and be more durable

· WMG at the University of Warwick will research and model new and existing manufacturing processes to unlock full potential of electrochemical materials in cells

The Faraday Institution funded “Nextrode” project, involving WMG at the University of Warwick, will research ways to make electrodes for Li-ion batteries which unlock the electrochemical potential of their ingredients.

WMG, at the University of Warwick, is one of six university partners in the Nextrode project, which is led by the University of Oxford, alongside six industry partners – including the UK Battery Industrialisation Centre (UKBIC) who will be researching how to make electrodes for Li-ion Electric Vehicle batteries more efficiently.

Today’s Li-ion batteries are made using a 'slurry casting' process, whereby the active materials are mixed in a wet slurry and coated onto thin foils of aluminium or copper, then dried and compressed. This process is highly effective for mass production, but is developed empirically through trial and error, at great cost to the manufacturer.

In this project, WMG will gain greater depth of knowledge in that process with a view to being able to predictively model and optimise it, so that future electrodes can be cheaper, store more energy, and get to market faster. To do this, WMG will use their state-of-the-art “battery scale up” facility, as well as taking data from the UKBIC when it opens next year.

Furthermore, slurry cast electrodes limit the performance of the battery as the active electrochemical materials are uniformly distributed throughout the electrode structure. Research has shown that arranging the materials in a structured way can dramatically improve battery performance, but at present there is no mass-manufacturing route to do so. This project will investigate new manufacturing methods to create structured electrodes in a cost effective way at high manufacturing volumes.

Professor David Greenwood from WMG, University of Warwick comments:

Professor David Greenwood from WMG, University of Warwick comments:

“Battery manufacturing is a critical industry for the UK to grow. It is highly competitive, and to win, we will need excellence in both science and manufacturing. The Nextrode project brings these two elements together to make future Li-ion batteries for Electric vehicles more energy efficient and affordable. Our unique research facilities are key to acquiring the knowledge required to deliver a step change in industrial capability."

Professor Patrick Grant from Oxford University who will lead project comments:

“Nextrode aims to strengthen the scientific understanding of existing electrode manufacturing so we can make it more flexible and extract further performance gains, but we will also develop a new generation of manufacturing approaches for ‘smart” electrodes where the different electrode materials are arranged with greater precision and provide even greater performance benefits. We anticipate these benefits could be realised for almost any type of battery chemistry”.

This project is just one of five that the Faraday Institution has announced today, 4th September. In total, it will award up to £55 million to five UK-based consortia to conduct application-inspired research over the next four years to make step changes in the understanding of battery chemistries, systems and manufacturing methods.

Business Minister, Nadhim Zahawi comments:

“Today’s funding backs scientists and innovators to collaborate on projects that will deliver a brighter, cleaner future on our roads. We are committed to ensuring that the UK is at the forefront of developing the battery technologies needed to achieve our aim for all cars and vans to be effectively zero emission by 2040.”

Neil Morris, CEO of the Faraday Institution comments:

“It is imperative that the UK takes a lead role in increasing the efficiency of energy storage as the world moves towards low carbon economies and seeks to switch to clean methods of energy production. Improvements in EV cost, range and longevity are desired by existing EV owners and those consumers looking to purchase an EV as their next or subsequent car. Our research to improve this web of battery performance indicators (which are different for different sectors) are being researched, with a sense of urgency, by the Faraday Institution and its academic and industrial partners. Our fundamental research programmes are putting the UK at the forefront of this disruptive societal, environmental and economic change.”

UK Research and Innovation Chief Executive, Professor Sir Mark Walport, comments:

“Bringing together experts across industry and academia, this exciting research will grow our understanding of battery chemistries and manufacturing methods, with the potential to significantly improve the UK’s ability to develop the high-performance electric vehicles of the future.

ENDS

4 SEPTEMBER 2019

Notes to Editors

Full list of Institutions include:

University of Birmingham

University College London

University of Oxford

University of Sheffield

University of Southampton

University of Warwick

For further information about the Faraday Institution visit: https://faraday.ac.uk/

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

The British Science Festival is coming to Coventry and Warwickshire

One of Europe’s largest science festivals is coming to town between September 10th and 13th.

With a schedule comprising more than 100 free events, activities and performances, the British Science Festival will “transform the region into a celebration of science and culture”.

The festival will feature talks from a selection of WMG experts, including Erik Kampert - Senior Research Fellow, Dave Greenwood – Professor of Advanced Propulsion Systems, Mark Williams – Professor of Metrology and Alan Chalmers – Professor of Visualisation.

Held in partnership with the University of Warwick, the programme highlights local strength in digital technologies, smart cities and the future of energy and healthcare.

There’s a special emphasis on the fun, thought-provoking, and societal aspects of science to show how it’s not just confined to laboratories, but something that’s all around us.

Plus, there will be a special filming of The Sky at Night: Question Time with Dr Maggie Aderin-Pocock and Professor Chris Lintott.

Other highlights include interactive experiences like a live 3-D psychedelic show and festival carpool in a driverless pod, discussions on how ‘gaming becomes gambling’, how AI could revolutionise cancer treatment, and how to tackle food poverty with food writer Jack Monroe.

Not to mention, a mud kitchen and tea-blending for adults and a takeover of Coventry’s FarGo Village with comedy, artistic workshops and an escape room.

Researchers convert car batteries into units that could power farms in the developing world

As part of a Circular Economy for electric vehicle battery systems, as the number of such vehicles increases rapidly, the need to find the best way to reuse and recycle vehicle batteries becomes just as intense.

In partnership with Jaguar Land Rover, Connected Energy and Videre Global, researchers at WMG, University of Warwick, have found a way not just to recycle those used batteries, but repurpose them as small energy storage systems (ESS) for off grid locations in developing countries or isolated communities.

The repurposed units, each containing approximately 2kWh of energy capacity, will be able to power a small shop, a farm holding, or multiple residential homes.

WMG’s Professor James Marco who was lead researcher on the project said:

“When an electric vehicle’s battery reaches the end of its useful life it is by no means massively depleted. It has simply reached the end of its useful life in a vehicle.

"It is generally accepted that an EV battery has reached end of life when its capacity drops to 80% of a fresh battery. While this is no longer enough to satisfy drivers, it remains immensely useful for anyone who seeks to use the battery in a static situation.”

While such partially depleted batteries remain potentially very useful to other users there are still challenges to overcome, particularly to ensure that they can be used reliably, sustainably, and cheaply in remote locations. These challenges include:

· How to protect the lithium-ion cells from over-charge and discharge

· Can the ESS be made compatible with a variety of other used battery cells and modules from other manufacturers

· How to keep it low cost and easy maintenance, while providing an interface that is easy to use and understand

The WMG team, at the University of Warwick, set about overcoming these challenges with the help of the WMG HVM Catapult and Jaguar Land Rover who supplied batteries and components from the Jaguar I-PACE, their first all-electric performance SUV. The team designed a new Battery Management System (BMS) and packaging that allowed them to create a working and easily portable prototype ESS which included:

• The use of standard low cost components for control, communication and safety functions. All parts were either sourced from the JLR service department or were low cost components purchased from any electrical retailer.

• The ability to use different modules that could be interchanged within the 2nd-life system without having to recalibrate the whole BMS

• Enough energy for a small shop, farm holding or multiple residential homes

• Multiple 12V DC sockets and 5V USB charge ports

• The ability to have the 2nd –life module charged via reclaimed laptop chargers

• Simplified control system for easy integration and deployment

Professor James Marco continues:

“This is a great result that not only provides a highly efficient repurposing solution for automotive batteries but which could also change lives in remote communities. We are now looking for support to allow these new units to be further developed and tested in remote or off grid locations.”

The research project was part of the Innovate UK funded Project: 2nd hEVen (2nd-Life Energy Storage Systems) and is supported by the WMG High Value Manufacturing (HVM) Catapult.