Departmental news

Robocrop: The robot assistants helping farmers to increase productivity

The future of farming could involve robots– as farmers seek to address labour shortages and increase crop yields.

Researchers at WMG at The University of Warwick are investigating how they can apply autonomous robotics to greenhouses and croppable fields.

Continuous and repetitive monitoring of crops is vital for fruit and veg production, as the sooner that pests, diseases and infrastructure issues can be spotted, the sooner they can be rectified.

This means that growers get the information they need to make quick decisions that save their crops and reduce losses.

A state-of-the-art Crop Monitoring Robot (Crombot) is proving that robots could become the perfect helper to support growers – especially when faced with labour shortages. Crombot is an autonomous four-wheeled robot, able to navigate itself around a green house, avoiding other workers and even following specific workers on command.

Crombot’s robotic arm has a camera on the end which allows it to carry out all the required monitoring duties, and can even identify the ripeness levels of strawberries, letting the grower know which areas of the greenhouse is ready to be picked.

Other developments by the group include "Spot", an autonomous four-legged robot dog supplied by Boston Dynamics, for use in agriculture. Spot is designed to work in difficult and hazardous environments, and this innovative robot system has proven itself so far to be very impressive in handling a variety of greenhouse and outdoor environments.

Benefits of this system include being able to walk up and down steps, over heating rails and other obstacles as well as tackling muddy fields.

By working in close collaboration with the University’s School of Life Sciences (SLS) at the Warwick Crop Centre on the Innovation Campus Stratford-upon-Avon, the WMG team have been able to combine their robotics expertise with the plant science expertise of SLS to create this extremely promising research.

This has laid the foundation for the group to now explore new capabilities such as automated planting and harvesting.

Harry Boyce, Project Engineer at WMG at the University of Warwick added: “Our research with Crombot aims to address growers’ scepticism of new technology and, most importantly, cost. It will unlock the potential for adoption of robotics solutions in horticulture, and facilitate a UK offering to a huge global market.

Alex Keller, Principal Engineer at WMG at the University of Warwick, said: “Boston Dynamic’s Spot robot could be an ideal solution for an agricultural monitoring robot, but it is currently very expensive and further research is needed to understand if Spot could progress to challenges such as harvesting and more.

“This is why we are continuing to develop our in-house robotic capabilities, so that we can help industry to create robotic solutions that are affordable and realistic for the grower, which still deliver high impact and high return on investment.

“We hope to hear from growers who would like to be involved in this research – finding out how they can incorporate robots in their practices too.”

Find out more about WMG here https://warwick.ac.uk/fac/sci/wmg/ or contact wmgbusiness@warick.ac.uk.

Notes to Editors

University of Warwick press office contact:

Annie Slinn

Communications Officer | Press & Media Relations | University of Warwick

Email: annie.slinn@warwick.ac.uk

WMG secures funding for two new knowledge transfer partnerships with SME manufacturers pushing the boundaries on process and management innovation

The SME Group at WMG, University of Warwick, has embarked on two major projects with Bellagio Stone and Radius Systems thanks to over £200k in funding from Innovate UK’s Knowledge Transfer Partnership (KTP) scheme.

funding from Innovate UK’s Knowledge Transfer Partnership (KTP) scheme.

A KTP is a three-way collaboration between a company, an academic institution (in this case WMG at the University of Warwick) and a graduate or postgraduate. KTPs are designed to help businesses improve their competitiveness and productivity through shared knowledge, technology, and skills.

Bellagio Stone’s two-year project will create a new cultural management and leadership framework within the business following a recent merger, enabling it to push productivity and prepare for future expansion. Bellagio will transform its operations in the stonemasonry industry, capitalising on a range of long-term growth ambitions.

Radius Systems manufacturers of innovative plastic pipeline solutions will work on a two-year project with WMG to analyse, design and implement a process control system to reduce process variation in the continuous manufacture of water, gas and hydrogen infrastructure pipes.

Simon Broome, Innovation Manager at WMG who works with SMEs to secure KTP funding said: “We are delighted to announce these major new KTP projects. Both Bellagio Stone and Radius Systems have showed a fantastic appetite to grow their businesses and engage with the University to achieve their goals. We are excited about the potential ahead and are now in the process of recruiting the KTP Associates who will deliver the projects in the businesses.”

Mike Boyden, Operations Director at Bellagio Stone Ltd said: “We are really excited to have been awarded the funding to begin the KTP project in conjunction with WMG. We have worked on a number of really successful projects with WMG in the past and feel the KTP has great potential to help develop our business further. Having recently completed a business merger, this targeted approach of supporting specific hurdles we are facing, will help unite both businesses and really drive improvements in productivity, purchasing power and overall efficiencies. We are really grateful to all the team involved with supporting the application and look forward to getting started.”

Allen Clarke Technical Director at Radius Systems Ltd said: “We are delighted to be awarded the funding through Innovate UK and the opportunity to further work with WMG. We have many ideas and initiative to further enhance our manufacturing processes and drive or business to the next level. The scheme will give us great insight into our chosen technical subjects whilst enhancing our World class manufacturing and Industry 4.0 philosophy. Thank you to all involved with this venture and looking forward to getting started in Autumn 2023.”

Find out more about WMG’s SME programmes here: WMG SME Group | How can we help you? (warwick.ac.uk)

WMG celebrates first cohort of Digital and Technology Solutions Degree Apprenticeship graduates

Congratulations to the first apprentices to complete a Digital and Technology Solutions Degree Apprenticeship at WMG, University of Warwick, who graduated at the end of July. Of the 68 graduates, an impressive 44% achieved a first class degree.

Congratulations to the first apprentices to complete a Digital and Technology Solutions Degree Apprenticeship at WMG, University of Warwick, who graduated at the end of July. Of the 68 graduates, an impressive 44% achieved a first class degree.

Established in 2019, the BSc Digital and Technology Solutions (DTS) Degree Apprenticeship has been developed in collaboration with employers in the engineering sector. The programme brings together academia and industry to empower early talent to become confident technology solutions professionals.

As technology advances and the digital skills gap in the UK widens, employers are seeking new ways to innovate and adapt. Apprentices on the DTS Degree Apprenticeship spend four years studying and working, developing the high-quality skills that companies need for business growth. Apprentices graduate with the ability to deliver technology solutions to develop new products and services, and increase productivity using digital technologies.

WMG is passionate about supporting organisations with their workforce strategies, whether that be upskilling employees or recruiting new talent. The Degree Apprenticeship team has built strong employer partnerships to provide programmes that equip employees with the specialised skills that businesses need now, and for the future.

Edward Stone, Senior Careers Cohort Lead at JLR, commented on the impact of DTS apprentices on the business: “At JLR we have been involved from the inception of the DTS Degree Apprenticeship programme, working closely with WMG in its development and application for our business. The knowledge and skills being developed by our apprentices play a key part in closing a critical skills gap fundamental to the ongoing success of JLR as we undertake the transformation of our business to meet the ever-changing challenges of the automotive industry.”

Reflecting on this important milestone for our graduates and for the DTS Degree Apprenticeship programme, Professor Gill Cooke, Pro-Dean (Education) at WMG said: “I am delighted that DTS has had its first graduating cohort; WMG colleagues have completed some incredible work to enable our students to graduate on the course across various discipline streams. Well done to our first graduates!”

Associate Professor and Course Lead for the DTS Degree Apprenticeship programme, Dr Alaa Al Sebae, added: “I was filled with joy when witnessing the first cohort of graduates walking across the stage with smiles and pride. Their dedication and hard work over the past four years studying while working have set an exceptional standard for future learners. We are truly proud of their accomplishments and have no doubt that they will continue to shine brightly in their current and future careers.

“We hope to maintain close connections, and that they visit frequently as guest speakers to inspire future cohorts. Congratulations once again to our graduates, and may you move forward to make a positive impact in the world!”

Associate Professor and DTS Degree Apprenticeship Founding Course Leader and Course Designer, Dr Freeha AzmatLink opens in a new window, said: “It was a huge pleasure to welcome the first DTS cohort to WMG four years ago, and I am so excited to see all of them progressing to the next stage of their careers now.

“The continuous effort and hard work of apprentices, close collaboration between employers and the University team from course inception to the delivery phase has made this programme successful. Congratulations to all.”

For more information about WMG Degree Apprenticeships, please contact the team or visit the website.

International experts developed the foundational ISO standard for the safety of self-driving vehicles

A new international standard has been published which lays the foundations for safe deployment of self-driving vehicles by creating a common approach to define the operating conditions of self-driving vehicles, which is also known as the Operational Design Domain (ODD) (i.e., operating conditions).

A new international standard has been published which lays the foundations for safe deployment of self-driving vehicles by creating a common approach to define the operating conditions of self-driving vehicles, which is also known as the Operational Design Domain (ODD) (i.e., operating conditions).

Led by Professor Siddartha Khastgir from WMG, University of Warwick, UK, and supported by an international group of experts, the very first international standard for safe operation of self-driving vehicles, Road Vehicles — Test scenarios for automated driving systems — Specification for operational design domain – ISO 34503 has been published. This standard will be relevant to every self-driving vehicle developed and manufactured anywhere in the world. The new standard is based on BSI PAS 1883, developed by BSI the UK National Standards Body.

In simplistic terms, ODD is a definition of where your self-driving vehicle is going to operate. This standard provides specifications for defining these operating conditions in a common manner.

The standard classifies ODD into three key categories:

· Scenery elements: non-movable elements (e.g., roads, bridges, traffic lights),

· Environment conditions: weather and other atmospheric conditions; and

· Dynamic elements: all movable objects and actors.

The importance of the concept of ODD is highlighted in the latest European Union’s Act on Automated Driving System (adopted in Aug 2022) which puts the concept of ODD as a cornerstone of the safety assurance process of an automated vehicle. Similar approaches are being considered at the upcoming regulations at United Nations Economic Commission for Europe.

This international standard is a big step to facilitate the commercialisation of self-driving vehicles in a wider global society while also safeguarding the safety of this emerging technology. International organisations and local governments or regulatory agencies can use this standard as a guide to develop their regulations and policies on self-driving vehicles. Autonomous vehicle developers and manufacturers around the world can now design and test their technology based on internationally aligned safety benchmarks, create accurate marketing and communication materials, and build societal trust in the technology.

WMG in collaboration with BSI committee AUE/15 Safety related to vehicles, worked with global partners in countries such as United States, Germany, Japan, China, France, Austria, Canada, Israel, Sweden, Finland, South Korea, Australia, to develop and finalise the ISO standard for the safety of automated vehicles.

Professor Siddartha Khastgir, Head of Verification & Validation, Intelligent Vehicles said:

“Defining the Operational Design Domain is the first step in designing a safe self-driving vehicle. Furthermore, due to the diversity in stakeholders in this ecosystem (e.g., developers, regulators, local authorities etc.), it is essential we have a common way to define such a fundamental concept of safety.

“Successful standardisation efforts are only possible with true international collaboration. I am grateful to experts from various countries worldwide who have engaged and contributed actively to this standard. I am pleased to see more efforts kick-starting which building on the concept of ODD and this standard.”

This standardization activity is underpinned by strong research outcomes from the CCAV and Innovate UK funded OmniCAV research project by WMG; and also, by the research conducted as part of Professor Khastgir’s UKRI Future Leaders Fellowship.

Nick Fleming, Associate Director, Transport and Mobility, BSI said:

“It’s exciting to see the launch of this new international standard, given the potential benefits that can be realized by testing automated vehicles so they can operate safely on our roads. Having a common language to describe the Operational Design Domain (ODD) of an automated vehicle, with the ODD effectively describing the environment and conditions that an automated vehicle is capable of operating in, will be valuable to test and deploy these vehicles safely.

“This new ISO standard has been inspired by the UK document, BSI PAS 1883:2020, the first taxonomy for ODDs developed in conjunction with UK experts and the government’s Centre for Connected and Automated Vehicles (CCAV).

“BSI would like to thank Professor Khastgir for his effort in helping to lead this work at the international level which, along with BSI PAS 1883, shows the leadership the UK is having in the development of global standardization for automated or self-driving vehicles.”

Sarah Gates, Director of Public Policy at Wayve, said:

“We’re pleased to see the launch of this new international standard. The concept of ODDs is the basis of deploying self-driving vehicles safely. A common way of describing ODDs across industry is therefore vital for creating the highest safety standards, bolstering public trust and supporting the regulatory frameworks required to commercially deploy self-driving technology on a global scale.

“We look forward to continuing to work closely with WMG to ensure that safety standards for self-driving technology are rigorous, and to increase confidence in the exciting technology we’re developing here at Wayve, which will unlock a safer, smarter and more sustainable transport system.”

ISO 34503 was developed by ISO technical committee ISO/TC 22/SC 33 Vehicle dynamics, chassis components and driving automation systems testing.

It can be purchased from your national standardisation body or through the ISO Store.

This standardisation activity is underpinned by strong research outcomes from the CCAV and Innovate UK-funded OmniCAV research project by WMG; and also, by the research conducted as part of Professor Khastgir’s UKRI Future Leaders Fellowship.

NOTE TO EDITORS: Link to ISO 34503: https://www.iso.org/standard/78952.html

Media contact: Annie Slinn, Communications Officer (Sciences), Annie.Slinn@warwick.ac.uk | Caitlin Evans, WMG Marketing and Communications Executive, Caitlin.Evans@warwick.ac.uk

WMG supports holiday workshops

WMG at the University of Warwick’s Outreach Team was pleased to take part in the Royal Institution’s (Ri) holiday workshops.

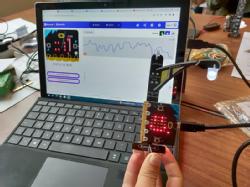

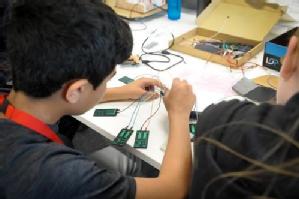

Professor Margaret Low and Dr Phil Jemmett both led sessions at the holiday workshops designed to bring all areas of science - including mathematics, computing and engineering - to life for 9 to 14 year olds.

Professor Margaret Low and Dr Phil Jemmett both led sessions at the holiday workshops designed to bring all areas of science - including mathematics, computing and engineering - to life for 9 to 14 year olds.

Professor Margaret Low’s session was a fun and creative introduction to programming using TurtleStitch. TurtleStitch is free, easy to use, and generates patterns that can be stitched by embroidery machines, enabling the creation of physical things from code.

At Dr Phil Jemmett’s session he asked, ‘Where is engineering?’ Dr Jemmett explained how every product, tool, device and service relies on engineers designing, refining and creating solutions to problems. Students used programmable electronics and sensors, and had the opportunity to make a product for the future.

Dr Phil Jemmett, Widening Participation Co-ordinator at WMG, University of Warwick, said: “The Royal Institution has centuries of tradition in educating people about science in a fun and engaging way. We are so proud to have supported the holiday workshop programme for another year, and continue to work with one of the most famous scientific bodies in the world. What better place to showcase the engineering and innovation that WMG is part of in building the future? We aimed to show people how simple it can be to start to create their own projects, whether making a smart city for the future, or controlling an embroidery machine in Margaret’s workshop. And it really showed in the engagement of the students in the activities – the things they were able to build in one day were mind-blowing.”

people about science in a fun and engaging way. We are so proud to have supported the holiday workshop programme for another year, and continue to work with one of the most famous scientific bodies in the world. What better place to showcase the engineering and innovation that WMG is part of in building the future? We aimed to show people how simple it can be to start to create their own projects, whether making a smart city for the future, or controlling an embroidery machine in Margaret’s workshop. And it really showed in the engagement of the students in the activities – the things they were able to build in one day were mind-blowing.”

Professor Margaret Low, Director of Outreach and Widening Participation at WMG, University of Warwick, showed her commitment to making science accessible: “Science, engineering, mathematics, and computer science are not traditionally seen as being fun subjects to dip into. With these workshops we were able to provide an inspiring introduction for young people, and perhaps set them on a path to becoming scientists or engineers in the future. Working in partnership between a university and a public body like the Ri is a good example of how we can create opportunities for young people to discover what they want to do, and be empowered to achieve it.”

Peter Gallivan, Family Programme Manager, at the Royal Institution, explains: “Holiday Workshops at the Royal Institution are one of the main ways we work with young people, welcoming around 2,000 young people across the summer to get hands-on exploring STEM subjects. The sessions run by Margaret and Phil are some of my favourites, as they showcase how creativity and imagination are important skills used by scientists and engineers. It was a delight to see their sessions packed full of excited young scientists happily working together to solve a variety of engineering challenges. How else would you want to spend your summer holidays?!”

Find out more about WMG’s Outreach programmes here: https://warwick.ac.uk/fac/sci/wmg/about/outreach/

Project workshop addresses cyber-security in connected and autonomous mobility

Researchers from WMG, at the University of Warwick, were pleased to welcome partners and guests to a live trial and project workshop on the AirQKD project.

Researchers from WMG, at the University of Warwick, were pleased to welcome partners and guests to a live trial and project workshop on the AirQKD project.

AirQKD addresses the cyber security of Connected and Autonomous Vehicles (CAV) and specifically addresses components, manufacturing, software, and testing for last-mile Quantum Key Distribution (QKD) systems between shared parties for 5G and connected cars.

It is an Innovate UK funded collaboration between BT; Lexden Technologies; OLC; Duality, Bristol University; Fraunhofer Centre for Applied Photonics; Strathclyde University; WMG; Bay Photonics; Heriot Watt University; Angoka; ArQit; Nu Quantum; National Physical Laboratory; CSA Catapult and Edinburgh University.

The trial combines BT’s expertise in building quantum-secure networks using QKD – an essentially un-hackable, cutting-edge technique for sharing encryption ‘keys’ between locations using a stream of single photons) with other new techniques for applying quantum security to mobile devices, developed by UK start-ups Nu Quantum, Angoka and Duality.

On the University of Warwick campus, as part of the Midlands Future Mobility testbed, WMG has created a Vehicle to Infrastructure (V2I) testing facility enabling AirQKD partners’ technology in key management, key consumption, and security protocols to be used for secure communications.

The AirQKD system implements Free Space Optics (FSO) cryptographic key generation and standards-compliant key management. WMG is now managing the workstream between telecommunications (4G/5G cellular at BT’s Adastral Park site) and V2I communications on the University of Warwick campus. In combination, these technologies will be used to deliver an ultra-secure link between connected 5G towers and mobile devices, as well as to connected cars.

the workstream between telecommunications (4G/5G cellular at BT’s Adastral Park site) and V2I communications on the University of Warwick campus. In combination, these technologies will be used to deliver an ultra-secure link between connected 5G towers and mobile devices, as well as to connected cars.

Find out more about CAV research at WMG here: https://warwick.ac.uk/fac/sci/wmg/research/cav/connectivity/

Read more about AirQKD here: https://warwick.ac.uk/fac/sci/wmg/research/transformation/securecybersystems/projects

Congratulations to the WMG Class of 2023

On Thursday 27th July, WMG celebrated the success of its latest graduates.

With a total of 562 Master’s, Undergraduate, Postgraduate and Research students graduating, the team at WMG is very proud of everything the Class of 2023 has achieved.

There were 150 Undergraduate students, 76 of whom completed a Degree Apprenticeship, 73 studied full-time with one studying part-time.

For Postgraduate there were 383 Master’s students; 267 were full-time students, 31 part-time, and 85 studied overseas.

There was a further two MSCRs (Masters by Research), 22 PhD, and five EngD students.

Professor Gill Cooke, Director of Education, at WMG, University of Warwick said: “We are incredibly proud of our graduates. They have worked incredibly hard, and we hope they enjoy celebrating their achievements. We wish them all the best for the next stage of their careers.”

To find out more about studying at WMG visit https://warwick.ac.uk/fac/sci/wmg/education/

Warwick student wins logistics research award for supply chain dissertation

Pablo Brereton Rodrigo, a School of Engineering student at the University of Warwick, has won the Logistics Research Network Undergraduate Dissertation of the Year Award 2023, from the Chartered Institute of Logistics and Transport (CILT).

Pablo Brereton Rodrigo, a School of Engineering student at the University of Warwick, has won the Logistics Research Network Undergraduate Dissertation of the Year Award 2023, from the Chartered Institute of Logistics and Transport (CILT).

Pablo has recently completed his degree in Engineering Business Management. This undergraduate degree, although part of the School of Engineering, is led by the education team at WMG, University of Warwick.

Pablo’s dissertation entitled “Integrating supply chains in a turbulent, complex and uncertain era” was nominated by Professor Rob Thornton, Director of Undergraduate Programmes, at WMG. Pablo will be presented with his certificate and prize money at the Logistics Research Network Conference (LRN 2023) dinner and awards ceremony on the 7th September 2023 at Herriot-Watt University.

Professor Thornton explained: “Pablo’s dissertation was nominated for this award, for both academic excellence and the challenging topics addressed, which are highly relevant to today’s turbulent supply chains.”

Pablo said: “In discussing topics such as supply chain integration, I explored the challenging and turbulent landscape in today’s business environment and applied it to modern-day supply chains to reach the conclusion that forward-looking firms will leverage supply chain integration through self-contained, cross-functional and digitalised many-to-many structures.

“Directly applying skills learned during my placement year in supply chains, this project has further developed my personal growth and competencies relevant to the field. As such, I am immensely grateful to my university tutor, Alexa Kirkaldy, and all my friends and family for the continued support throughout the project.”

Pablo’s research was supervised by Alexa Kirkaldy, Associate Professor and Director of Academic Integrity at WMG who said: “Pablo defined his project idea and objectives after a year in industry and was excited to delve into the topic of supply chain integration, reaching depth and breadth usually expected at Master’s level. In addition Pablo was a delight to supervise and I wish him well in his career within the semiconductor industry.”

Professor Georgia Kremmyda, Head of Teaching and Deputy Head of School of Engineering said: “On behalf of the School of Engineering and the Education team, I would like to warmly congratulate you for your amazing achievement. The award strongly highlights your effort, commitment and dedication to your studies. You should take time to celebrate what you have accomplished.”

Professor David Towers, Head of School at the School of Engineering added: “This is quite an achievement and definitely something to capture on your CV!”

To find out more please visit: WMG - The University of Warwick

Widening participation work experience week connects under-represented aspiring engineers with industry giants

The University of Warwick's commitment to widening participation and fostering inclusivity took centre stage during a week-long programme aimed at inspiring 30 students from local schools to pursue careers in engineering. The initiative was organised by WMG at the University of Warwick and the University's Widening Participation Team which wanted to support under-represented students that might lack confidence or support when they consider a future in engineering.

inspiring 30 students from local schools to pursue careers in engineering. The initiative was organised by WMG at the University of Warwick and the University's Widening Participation Team which wanted to support under-represented students that might lack confidence or support when they consider a future in engineering.

Throughout the programme, participants gained valuable insights into various engineering pathways and learnt more about research and careers at WMG alongside partners like Tata Motors. WMG research and teaching staff mentored the students, providing them with a taste of what studying engineering involves through an engineering project.

Laboratory and workshop tours, facilitated by WMG apprentices and Tata Motors, gave participants firsthand exposure to the dynamic environment of an engineering workplace. The event culminated in a showcase where the students presented their projects, highlighting both their engineering skills and the knowledge they gained during the week.

The project was also supported by student ambassadors from across the University; Drishti, David, Ana, Brij, Sheerah, Diya, Michelle, Gabe and Chinmay, giving the young visitors to our campus an experience of what studying in Higher Education is like. The Widening Participation team also gave a session providing information, advice and guidance on how they might enter university study. Throughout the week, young people therefore had experiences and interactions all the way from undergraduate level through the University hierarchy to the Dean of WMG.

The project was also supported by student ambassadors from across the University; Drishti, David, Ana, Brij, Sheerah, Diya, Michelle, Gabe and Chinmay, giving the young visitors to our campus an experience of what studying in Higher Education is like. The Widening Participation team also gave a session providing information, advice and guidance on how they might enter university study. Throughout the week, young people therefore had experiences and interactions all the way from undergraduate level through the University hierarchy to the Dean of WMG.

One participating student said: "Visiting the National Automotive Innovation Centre with Tata Motors has opened my eyes to what engineering is really like, and I would like to learn more about degree apprenticeships with the University of Warwick.”

Another said: "I would describe this programme to a friend as an unmissable and eventful opportunity which I would heavily recommend as it has boosted my skills and given me a greater insight into careers, apprenticeships and university as a whole which has inspired me to want to go to university.”

Professor Robin Clark, Dean of WMG said: “There is a clear pathway from this point to being professional engineers. There may be many routes – whether through an apprenticeship or through a taught degree programme – but the skills and experience needed for all those routes are the same: perseverance, determination, initiative, and curiosity. Having a product on display at this showcase also demonstrates plainly those qualities in the people who have made them.”

Dr Phil Jemmett, Widening Participation Coordinator at WMG said: "This work experience model has been in our minds since 2019 and this is the first time we've been able to run it at full scale. Students have been working with our engineers on group projects all week and have gone on a journey through engineering and rapidly prototyping equipment.

“Each challenge links to WMG research and to challenges in the real world that could help make our planet's future more sustainable. With the skills we have seen in these students this week I have no doubt that our STEM industry is in safe hands in the future. They have been amazing."

The University of Warwick's initiative reflects its dedication to providing equal opportunities in engineering education. By empowering less privileged local students and challenging misconceptions about the field, they are nurturing a diverse talent pool that will shape the future of engineering.

Find out more about WMG's Outreach programme here

Ends

Notes to editors

For media inquiries and interview requests, please contact:

Bron Mills, Bron.mills@warwick.ac.uk, +447824 540 720

Professor David Greenwood on UK Gigafactory announcement from TATA Sons/JLR

Reactive statement from Professor David Greenwood, CEO of the High Value Manufacturing Catapult and Director of Industrial Engagement at WMG at the University of Warwick

“This is fantastic news and secures the future of our UK auto industry which would otherwise have been lost by 2035. Furthermore, this secures the supply chain meaning we’ve kept those jobs for everyone across the country.

“This is fantastic news and secures the future of our UK auto industry which would otherwise have been lost by 2035. Furthermore, this secures the supply chain meaning we’ve kept those jobs for everyone across the country.

“This announcement means that the UK is now above “critical mass” for supply chain companies and therefore sets the UK up to be an attractive place for businesses in the supply chain to invest to supply upstream and downstream materials needed for electric vehicle production. As one of the UK’s biggest academic institutions working in the area of battery and electric vehicle innovation, this is great news for all 250 of our researchers – we will now see the results of our work used in UK based industries and benefiting UK taxpayers rather than being exploited by competitors abroad.

“This is the culmination six years work here at Warwick Manufacturing Group - we helped the UK government set up the Faraday Battery Challenge which was a key part of the then Government’s industrial strategy. That investment has now borne fruit. Clearly, we now need to define our future vision and strategy as the global industrial landscape evolves at breakneck speed.

“This means the Prime Minister has realised he must provide sufficient investment to ensure the country is a competitive runner in the global race to dominate the markets created by the massive green transition needed to avert climate catastrophe.”

Battery recycling

Researchers at the University of Warwick estimate that by 2040 339,000 tonnes of batteries are expected to reach the end of their life in the UK alone.

Prof David Greenwood adds: “While we are busy building all these electric cars, we also need to think about what happens at the end of their useful life. Batteries contain significant quantities of materials which are costly to extract and refine and which could be hazardous to the environment if improperly disposed of. Investment is needed to create suitable recycling facilities in the UK within the next few years, and beyond that further research is needed to allow economic recovery of much greater proportions of the battery material. In doing so we will protect the environment, secure valuable raw materials, and reduce the cost of transport.”

Gigafactory FAQs

What is a gigafactory?

A gigafactory is a large factory that produces large numbers of batteries for electric vehicles. Tesla has pioneered the concept in the US, with six factories so far to produce batteries for their cars.

Why do we need one?

In order to a compete internationally and help preserve the UK automotive industry battery production needs to be scaled up rapidly across both the UK and Europe. This situation is exacerbated by tariffs due to be imposed across the UK and EU unless a certain proportion of a car is produced in one of those jurisdictions.

As an EV battery makes up around half of a vehicle’s weight it is crucial the UK vastly scales up battery production. Gigafactories are the most efficient way to do this.

How are electric car batteries made?

EV batteries come in lots of different shapes and sizes but are all made up of many battery cells put together to form a battery pack.

To make a battery, we take electrochemically active materials, like graphite, nickel manganese, cobalt and lithium, and make powders from them. These powders are mixed with solvents and adhesives, then coated onto metal (aluminium or copper) foils which are then packaged together inside cells.

This is a very precise process – otherwise the quality of the battery is impacted. At WMG, around 20 battery cells per day can be produced. At a gigafactory, production would be closer to 20 cells per second.

How are batteries recycled?

To recycle batteries, fire is used to recover most of the metals. Water can then be used to get further metals that can’t be reached using heat alone. There are still difficulties however in recycling lithium or graphite, which make up a large percentage of the metals in the batteries themselves.

With 11 million tonnes of lithium-ion batteries expected to need recycling by 2030, the need to build domestic capacity to recycle them is greater than ever.