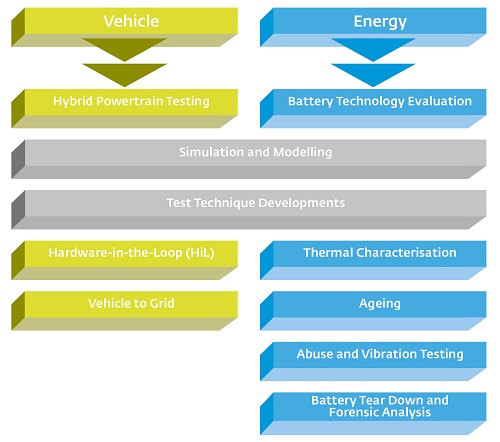

Battery Characterisation

Our research activities cover the full spectrum of testing and evaluations needed for Battery Characterisation as summarised below:

Hybrid Powertrain Testing

What are the interactions between powertrain components at a system integration level?

-

Different hybrid vehicle architectures on efficiency and emissions

-

Supervisory control strategies on efficiency and emissions

-

Component temperatures on efficiency

-

Vehicle usage conditions on battery lifetime

-

Motor and inverter design on high voltage bus EMI

Battery System Evaluation

How does battery cell performance match published data over a variety of usage scenarios?

Our energy storage research team is undertaking a programme of tests on commercially available battery technologies from cell to pack level, including: ageing tests, thermal testing, abuse and vibration testing. The team regularly tear down commercial battery packs to identify failure mechanisms which need to be addressed in next generation battery pack designs.

Simulation and Modelling

How can computer models be used to better understand the performance of batteries?

Our validated suite of models allows prediction of battery performance across a wide range of conditions and applications. The models range from high level 1st order models through equivalent electrical circuits and thermal models to electrochemical models. They are intended for use at vehicle level through to component level to gain an understanding of basic electrochemical phenomena affecting ageing.

Test Techniques Development

What is the best approach to testing batteries for automotive powertrain applications?

Our researchers are experienced in the test and characterisation of battery cells, modules and full battery packs and we are using our experience to develop next generation test strategies. While our primary focus is on vehicle propulsion applications, we are equipped to handle battery testing for other sectors including static power storage, consumer goods and aerospace.

Hardware-in-the-Loop Simulation

How can HiLS testing accelerate the understanding of battery technology?

HILS facilitates the transition from cell design to system design. HILS supports a fundamental understanding of the impact of realistic load cycles, cell

manufacturing uncertainties, cell-to-cell interactions and thermal variations on the performance and degradation of the complete Energy Storage System.

Thermal Characterisation

How much cooling is required for a battery? How does a battery behave at different temperatures?

Understanding the thermal behaviour of a cell, module and complete vehicle battery pack over a variety of operating conditions, including real world drive cycles, is key to the design and development of successful cooling systems. Our capability ranges from the thermal characterisation of a single cell through to the evaluation and optimisation of different vehicle pack cooling technologies.

Vehicle to Grid

Is there a benefit from using electric vehicles as grid level energy storage devices?

The Vehicle to Grid (V2G) concept uses parked electric vehicles to supply short-term power requirements to the electric grid. This is expected to become increasingly important as a growing number of uncontrolled renewable energy sources, such as wind turbines, are connected across the grid. It is also important for peak shaving applications and grid ancillary services. Previously studies have focussed on the situation where there are many electric vehicles connected so that there is always sufficient electrical storage to stabilise the grid beneficially. We have developed a Vehicle to Home (V2H) model which considers the interaction of individual vehicles and homes; this is more appropriate for the current low population of electric vehicles connected across the grid.

Battery Ageing

How will the performance of a given battery technology degrade over a range of different usage cases?

Understanding how & why a lithium-ion cell ages is critical to achieving the safe and reliable operation of a battery pack over its intended lifespan. Battery ageing research is helping to build our knowledge of different ageing factors, develop better models of cell ageing and create battery management strategies for long term reliable battery performance.

Abuse and Vibration Testing

What will happen to a battery in an extreme event? How does a battery and high voltage powertrain system behave under different vibration duty cycles?

Safety is a key concern in battery energy storage systems. Before selecting a battery for use in an application it is essential to test it over a full range of operating conditions. Our facilities include a comprehensive abuse testing facility which comprise two independent battery test chambers and a large shaker table for vibration testing of full size vehicle battery packs.

Battery Tear Down and Forensic Analysis

How can battery failure mechanisms be determined?

Battery tear down and forensic analysis are the techniques we use to identify failure mechanisms. High voltage battery packs can be disassembled to module or cell level. Detailed examinations can then be made of the constituent components including pouch cells, battery management systems, bus-bars, cooling plates, etcetera.