WMG News - Latest news from WMG

Neutron beam from nuclear reactor used to produce safer cars

A partnership led by WMG at the University of Warwick, with the Institut Laue-Langevin (ILL), Tata Steel, and the Engineering and Physical Science Research Council (EPSRC) is using a stream of neutrons from ILL’s nuclear reactor in a new project to examine the safety critical welds in cars made with boron steel.

Press-hardened boron steel is an ultra high-strength steel used across a variety of industries, with a particularly important application in the automotive industry. A large proportion of car manufacturers use boron steel for structural components and anti-intrusion systems in automobiles, as it provides high strength and weight-saving potential, allowing for stronger yet lighter cars, with increased passenger safety.

In the automotive industry, a major joining method for boron steel components is “resistance spot welding”, with several thousand welds being made on a single car. Spot welding exposes the boron steel sheet directly underneath the electrodes” to very high temperatures, causing the metal to exceed melting temperature and then rapidly solidify upon cooling. This results in a heat-affected zone, where surrounding material contracts and its microstructures are altered.

Dr Darren Hughes one of the WMG researchers on the project said:

“Automotive manufacturers and designers want to understand the exact effects spot welding has on boron steel, as the heat-affected zones can exhibit reduced hardness, which can in turn reduce the components strength. However most conventional scanning methods will struggle to penetrate such a strong and challenging material so we decided to seek out a partnership with a research facility that could give us access to more powerful means of conducting non destructive testing – a directed beam from neutrons beams generated by a nuclear reactor”

The WMG research team at the University of Warwick formed a collaboration between the the Institut Laue-Langevin (ILL), Tata Steel, and the UK’s Engineering and Physical Science Research Council (EPSRC) . The partnership have now begun to use neutrons generated from ILL’s reactor in its SALSA (Strain Analyser for Large-Scale Applications) beamline to examine the welds in boron steel and are already getting useful data due the neutron beam’s ability to penetrate heavy materials such as boron steel, and the fine resolution it provides.

WMG Research Fellow Dr Neill Raath, the lead researcher on the project, said:

“Our study determined for the first time a strong correlation between reduced hardness in heat-affected zones of boron steel spot welds and increased residual stress. The findings have indicated the need to develop new welding methods that do not have the same damaging impact on mechanical properties as spot welding, especially because there is nothing that can be done to avoid tempering when spot welding is used on boron steel.

Our study has shown the need to apply alternative welding methods that can lengthen the lifetime of the widely-used boron steel to its full potential. With several thousand welds being made on a single car, future work on minimal-heat input welding techniques and post-spot welding treatments will enable the boron steel components of cars to maintain their hardness and avoid residual stress. Importantly, this will ultimately provide top-tier passenger safety in stronger yet lighter vehicles.

The next step is to use the same technology to develop methods that can evade this issue. This will include magnetic pulse welding, which does not use heat and as such does not cause a heat-affected zone, and post-welding heat treatment, which reverses the reduction in hardness caused by spot welding. This will be of particular importance to industries that use boron steel such as the automotive industry.”

Dr Thilo Pirling, the ILL scientist leading ILL’s SALSA team, said:

“The SALSA beamline is a well-suited instrument for this study, as it specialises in determining residual stresses in a broad range of engineering materials, including steels. It also allows larger structures to be placed within the beamline. In this case, the non-destructive nature of the technique allowed the correlation of interest to be analysed effectively, as hardness profiles could be determined on the same weld following the neutron diffraction tests for residual stress.”

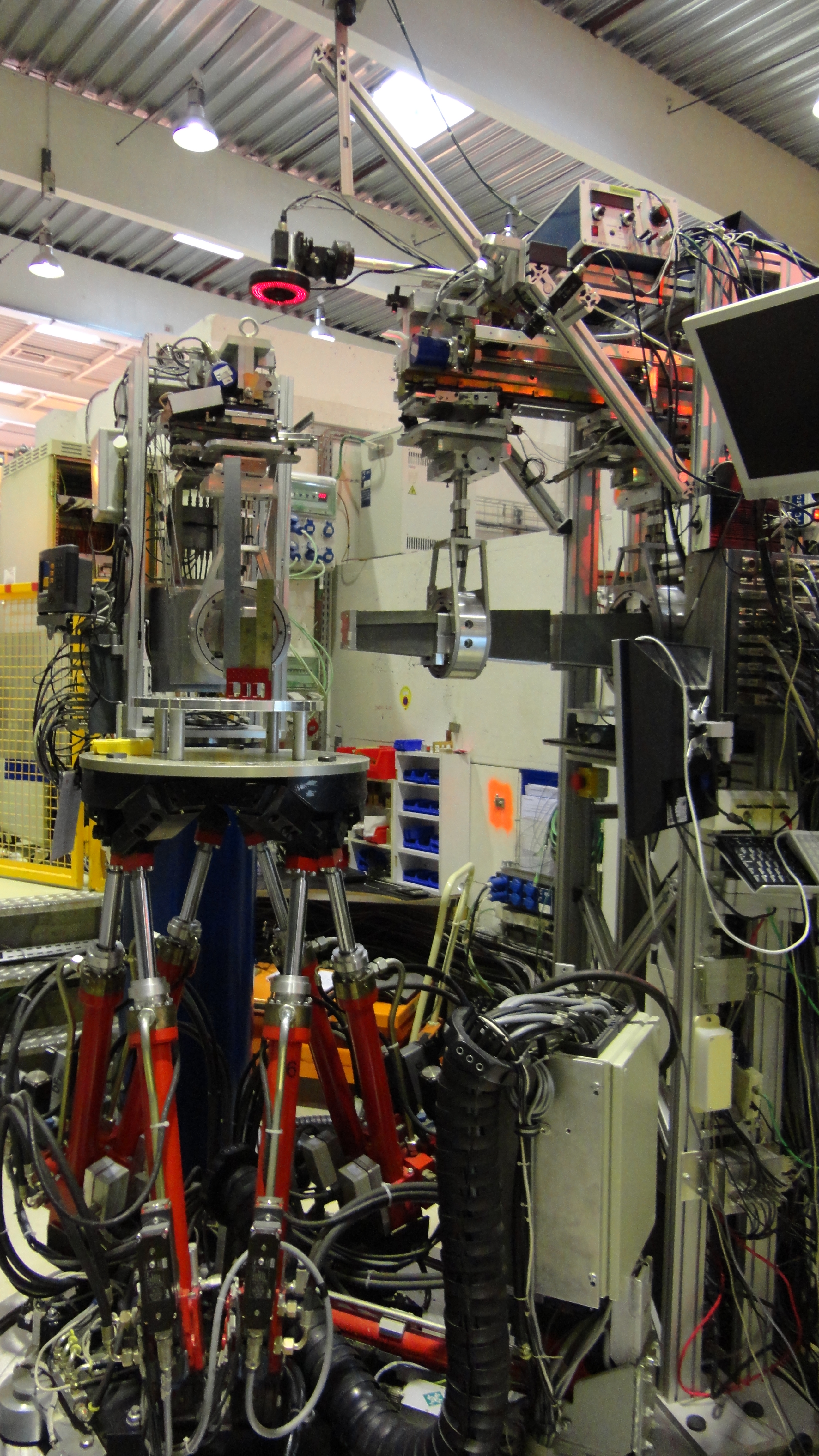

Image: Sample clamping stage on hexapod moving platform to enable accurate sample translation through neutron beam - CLICK FOR HIGH-RES.