WMG News

Digital supply chain visibility needed to rebuild after COVID-19

Manufacturers must unlock supply chain visibility to rebuild after the COVID-19 pandemic, WMG and Blue Yonder are warning.

The pandemic has disrupted supply and demand in many ways, from factory and border closures to swings in consumer needs, and those without supply chain visibility have been struggling to adapt and keep up. Digital supply chain technologies perform a vital role across all stages of manufacturing, from sourcing materials and quality control to warehouses and shipping. Now the industry is being warned any talk of ‘building back stronger’ won’t come to fruition if manufacturers don’t have the visibility over demand and supply that digital supply chains can bring.

The warning comes as a result of WMG research conducted in with almost 250 manufacturing companies revealing that lack of visibility and workforce issues are creating the biggest supply chain bottlenecks:

- 47% cited lack of visibility of capacity at suppliers and 37% cited lack of visibility of demand from customers as major supply chain constraints.

- More than half (55%) used inventory as the major buffer against disruption. This ties up cash and can leave organisations exposed if demand falls.

- Less than a third (32%) used visibility in their supply network to react to disruption. This is potentially a more effective strategy in the longer term.

To help manufacturers assess their supply chain needs, WMG at the University of Warwick and Blue Yonder worked together to design a freely accessible digital readiness tool. The digital readiness tool gives manufacturers the ability to assess their current supply chain to see where they are now and where they need to be. Manufacturers can also enquire about a further consultation to understand what they need to do to get to their goal and survive in the post COVID-19 world.Professor Jan Godsell, WMG, University of Warwick

Professor Jan Godsell, from WMG, University of Warwick, comments: “As we continue to deal with the disruptions of COVID-19, demand and supply visibility has never been more critical. It enables manufacturers to better plan their manufacturing operations, to minimise costly inventory buffers. We hope that the supply chain digital readiness tool can assist manufacturers with identifying opportunities to use digitisation to help their businesses to survive and thrive amidst the challenges of COVID-19. We are also offering manufacturers further advice.”

has never been more critical. It enables manufacturers to better plan their manufacturing operations, to minimise costly inventory buffers. We hope that the supply chain digital readiness tool can assist manufacturers with identifying opportunities to use digitisation to help their businesses to survive and thrive amidst the challenges of COVID-19. We are also offering manufacturers further advice.”

Alan Duncan, Senior Director of Manufacturing Strategy at Blue Yonder, adds: “They say ‘the wise man built his house on the rock,’ and when they’re rebuilding after COVID-19, manufacturers must put resilient digital supply chains at the centre of operations. Manufacturers have been investing more in the move to digital supply chains in recent years, but it’s crucial that their plans are pushed through to fruition. A digital supply chain will give them the end-to-end visibility, resilience and agility required to emerge from pandemic disruption in the strongest manner possible.”

ENDS

4 MARCH 2021

NOTES TO EDITORS

The data comes from a WMG survey of 248 manufacturers in September 2020.

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/january2019/jangodsell250.jpg

Caption: Professor Jan Godsell, WMG, University of Warwick

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

The three key actions to secure supply chain resilience after Brexit and COVID

Brexit and COVID were two major disruptions to manufacturers’ supply chains, however, a consortium of academic and industry partners including WMG, University of Warwick has identified key ways to build supply chain resilience.

A report by researchers from WMG, University of Warwick in conjunction with Argon & Co, Tata Consumer Products Ltd and Pinsent Masons has highlighted three practical solutions for supply chain resilience:

1. Risk management – Identifying risks throughout the supply chain to make wise decisions

2. Buffer management – Utilising inventory and capacity in the supply chain to react in a timely manner

3. Contract management – Increasing contracting agility to build a close tie with business partners

Supply chains have been under a significant amount of stress over the last year with Brexit and COVID-19, with three in four organisations likely to experience disruptions. Therefore, their resilience is key to recovery.

The complexity of supply chains means that disruptions can happen at any time. When COVID-19 hit the world in early 2020 firms had little time to prepare, but the report found that those that were able to adapt, supply flexibility and buffer manage were able to deal with the disruption more effectively.

but the report found that those that were able to adapt, supply flexibility and buffer manage were able to deal with the disruption more effectively.

Huge uncertainties lie ahead when it comes to Brexit, however with time to prepare, the industries can be ready for a number of different scenarios. Research has found the use of proactive practices such as planning and visibility and collaboration were effective in initial Brexit preparation.

In order to improve supply chain resilience it’s essential that there is an understanding of what exactly supply chain resilience is and planning ahead for it. Assessing just how resilient a manufacturer is by identifying vulnerable areas is the first step in preventing disruption.

This then leads onto managing buffers, for example optimising inventory stocks and production capacity, and with that being cooperative. A coordinated approach to supply chain planning enables great visibility and mitigates risks.

Professor Jan Godsell, from WMG, University of Warwick comments:

“Supply chain risks will always be unavoidable, however the quick succession of Brexit and COVID has rung a bell for suppliers to be prepared for any situation that may arise. Areas of preparation include identifying risk throughout the supply chain to inform better decisions, managing buffers to respond faster and adopting flexible contracting enables greater collaboration.

“We encourage all firms to consider these solutions, so their supply chain is more resilient and that ultimately they’ll be more sustainable in the long term.”

Clare Francis, partner at Pinsent Masons LLP adds:

“The last year has seen supply chains disrupted on an unparalleled scale. As businesses have moved from the initial challenges of ensuring supplies in the short-term they now need to focus on rebuilding resilient supply chains for the future. There are a number of areas that businesses must consider when doing this but they have an opportunity to learn from the lessons of Covid-19 and implement more resilient and better supply chains for the future.”

ENDS

23 FEBRUARY 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/february_2021/jan_godsell_supply_chain_resilience_figure_1.jpg

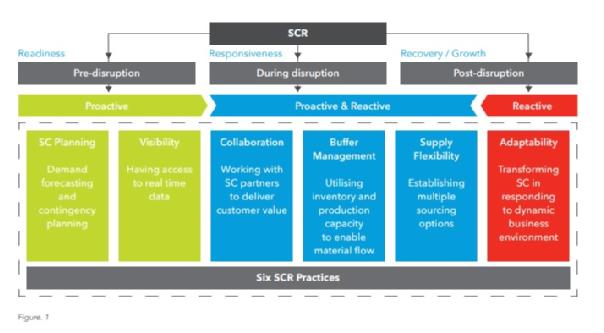

Caption: Types of supply chain resilient strategies pre-disruption, during disruption and post-disruption.

Credit: WMG, University of Warwick

Report available to view at: https://warwick.ac.uk/fac/sci/wmg/business/supply_chain_resilience_hub_report_-_final.pdf

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG working with Stratford Upon Avon Town Council on new research into sustainable transport

WMG, at the University of Warwick, is working with TravelSpirit Foundation on a government funded project which will focus on how new technologies could help create sustainable transport systems in Stratford upon Avon, Warwickshire.

Project Damascus is supported by Stratford Climate Action and Stratford upon Avon Town Council and has received funding from the Government’s Geospatial Commission. The first stage of the research, is a 3-month desktop study in Stratford upon Avon and Canterbury. The project is looking to shed light on how consolidating parcel journeys using mobility hubs could create a more pleasant experience for visitors and residents of Stratford upon Avon.

Janet Godsell, Professor of Operations and Supply Chain Strategy at WMG, University of Warwick is providing expert advice to the project. She said “This is an important piece of research. It has strong alignment with the government’s Green Industrial Revolution strategy and could have a widespread positive impact on many UK towns outside the larger metropolitan cities.”

Janet Godsell, Professor of Operations and Supply Chain Strategy at WMG, University of Warwick is providing expert advice to the project. She said “This is an important piece of research. It has strong alignment with the government’s Green Industrial Revolution strategy and could have a widespread positive impact on many UK towns outside the larger metropolitan cities.”

Project Damascus is led by Simon Herko, President of the Travelspirit Foundation, working in consortium with Iconic Blockchain, Peera and WMG, University of Warwick and was awarded funding through a competition delivered by Innovate UK.

The research team is interested to hear from people who already shop online, local courier drivers and retailers who sell to customers online. For more information, including opportunities to get directly involved in the research, please contact:

TravelSpirit Foundation, Simon Herko simon.herko@travelspirit.io

Stratford Climate Action: Stephen Norrie stratfordclimate@tutanota.com

Stratford Town Council: Jenny Fradgley Jenny.Fradgley@stratford-tc.gov.uk

Restarting the aluminium industry in the Black Country

The Black Country in Birmingham was the energy and innovation stomping ground in the 18th and 19th century, creating the UK’s industrial economy. Fast forward to the 21st century there is now a need to make a business model that’s more economically and environmentally sustainable.

With the help of WMG, University of Warwick, the Black Country LEP have made a future business model for Aluminium in the Black Country based on the  provision of low carbon energy sources, as part of a project Repowering the Black Country, which aims to make the Black Country the world’s first zero carbon industrial cluster.

provision of low carbon energy sources, as part of a project Repowering the Black Country, which aims to make the Black Country the world’s first zero carbon industrial cluster.

The aim of the project is to enable clean GVA growth of £16bn by 2030, creating or safeguarding at least 20,000 skilled jobs. Thanks to funding from Innovate UK researchers from WMG specifically looked at the Aluminium Industry in the area.

The researchers report that if the Black Country Strategic Economic Plan forecasts GVA growth of £16bn by 2030. The growth will be driven by reshoring of manufacturing from overseas and organic growth, particularly in high value manufacturing, building, transport and environmental technology sectors where the Black Country has long-standing strengths.

However, if this growth simply follows the structural templates and energy practices of the past, annual CO2 emissions from Black Country industry will almost double to 2.3M tCO2.

To deliver green growth and meet UK industrial strategy objectives researchers from WMG propose that the Black Country needs to take the opportunities created by Brexit and Recovery from Covid-19 to reconfigure and repower its industrial base and create a fundamentally new economic model for the area.

Professor Jan Godsell, from WMG, University of Warwick explains:

“This has been an exciting project for WMG to get involved in. By using circular supply chain principles, we’ve been able to demonstrate how re-industrialising around low carbon energy hubs in the West Midlands can help meet our net-zero carbon goal by 2050 but also create value-adding jobs for the region.”

Since the project has completed The Black Country Consortium has been awarded funding from UK Research and Innovation (UKRI) to support clean industrial growth through the Repowering the Black Country Project. This second round of funding, focused on helping the UK achieve net zero emissions as part of Government’s Clean Growth Strategy, will support businesses and local authorities in developing plans for zero carbon hubs and reducing energy costs across the Black Country.

Funded by UK Research and Innovation, on behalf of the UK government, Repowering the Black Country is one of only 7 projects funded nationally focused on helping the UK achieve net zero emissions by 2050 as part of the Industrial Decarbonisation Challenge. This is a key component of the government’s Clean Growth Strategy.

Tom Westley DL, Chair of the Black Country LEP Board said:

“This funding is another step toward the Black Country putting in place plans to decarbonise our industrial supply chains and lead the way nationally for industrial clean energy. The Repowering the Black Country project is a real partnership approach to planning for the future of our world-class industrial sector.

“This boost will enable the team to work across the Black Country with local authorities and industry to develop zero carbon industrial estates that optimise and generate clean energy in the most efficient way. Zero carbon means lower energy bills, lower carbon emissions and commercial opportunities locally – all of which will be good news for the Black Country economy.”

Energy Minister Kwasi Kwarteng said:

“The UK is leading the world’s green industrial revolution, with ambitious targets to decarbonise our economy and create hundreds of thousands of jobs.

“As we continue to level up the UK economy and build back greener, we must ensure every sector is reducing carbon emissions to help us achieve our commitment to net zero emissions by 2050.

“This funding will help key industrial areas meet the challenge of contributing to our cleaner future while maintaining their productive and competitive strengths.”

Andy Street, the Mayor of the West Midlands, said:

“Our region’s plan for economic recovery is all about delivering the high-paid, high skilled, ‘green’ jobs of the future. So this funding partnership is both good news for West Midlands jobs and industry, helping businesses grow while using less energy. So it’s great news for our environment.

“The West Midlands Combined Authority has an ambitious #WM2041 plan for the region to be carbon neutral by 2041. This Government funding for clean industrial development in the Black Country will help our region build on its long history of manufacturing, building a green economy that’s good for jobs and good for the planet.”

ENDS

7 JANUARY 2021

NOTES TO EDITORS

Images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/january_2021/repowering_jpeg.jpg

Caption: The Phoenix 10 site in the Black Country

Report available to view at: https://www.blackcountrylep.co.uk/upload/files/Repowering%20the%20Black%20Country%20A%20prospectus%20to%20lead%20a%20clean%20growth%20revolution%20in%20the%20UK.pdf

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

New engineering partnership to develop digital marketplace to improve manufacturing supply chain

A research team, including WMG at the University of Warwick, led by Swansea University College of Engineering, are developing a pilot online marketplace designed to optimise manufacturing supply chain networks and create a new industry-wide business model.

This new platform will seek to better connect manufacturers and suppliers, enabling a streamlined product/process sourcing and selection service tailored to industry needs, with the support of the Institute for Innovative Materials, Processing and Numerical Technologies (IMPACT).

The project will initially focus on supporting Welsh manufacturing companies with the aim to create an innovative digital supply chain marketplace (DSCM) template that can be replicated nationally and globally. One of the first companies to trial the new platform will be Swansea-based company MyMaskFit. Their aim is to produce custom fit reusable PPE masks for use during and beyond the COVID-19 pandemic. Customers will send a scanned image of their face to the company via an app designed to record the dimensions needed to create the bespoke product.

A challenge for many companies, like MyMaskFit, is often creating a new supply chain and sourcing the many products and services required to bring regulated products to market.

Unifying shared expertise with industry experts and researchers from WMG, University of Warwick and the Manufacturing Technology Centre, this new partnership will offer companies, like MyMaskFit, access to a more open and dynamic market, with increased opportunity for UK SMEs, and by making markets more efficient and flexible, should raise productivity and open new value chains through wider reach.

Jan Godsell, Professor of Operations and Supply Chain Strategy, WMG, University of Warwick, comments: “Major disruptions such as COVID-19 have challenged the conventional and static design of supply chains. Market places have an important role to play in connecting UK manufacturers with the emerging demand for new products and services. They support the development of new types of business models and dynamic supply chain designs, that will underpin the future of UK manufacturing. Self-assessment tools, roadmaps and blue prints will be made available through the ISCF Supply Chain Innovation Hub, so that these opportunities can be exploited by firms across the UK”.

Jan Godsell, Professor of Operations and Supply Chain Strategy, WMG, University of Warwick, comments: “Major disruptions such as COVID-19 have challenged the conventional and static design of supply chains. Market places have an important role to play in connecting UK manufacturers with the emerging demand for new products and services. They support the development of new types of business models and dynamic supply chain designs, that will underpin the future of UK manufacturing. Self-assessment tools, roadmaps and blue prints will be made available through the ISCF Supply Chain Innovation Hub, so that these opportunities can be exploited by firms across the UK”.

“The challenge of existing marketplaces is that the relevance and quality of data is subjected to manual scrutiny and intervention,” comments project lead, Professor Johann Sienz, Deputy Executive Dean, Faculty of Science and Engineering and IMPACT Director. “This marketplace will be designed to provide visibility and access to supply chain processes and will deliver live validated and relevant data to make decisions. It will be valuable to the supplier through creation of ‘one supplier-to-many customers’ with the additional benefits of reducing administrating expenses, and maximises volume leverage, with less IT integration requirement.”

“This ‘Made Smarter’ testbed will act as a template for other digital supply chain marketplaces to be created to serve other sectors, geographies and verticals, for instance exclusive communities for highly regulated industries, where trust in the access, integrity, and security of information is critical.”

Driven by industry feedback, this new DSCM will offer much-needed features such as accuracy and precision for parts; pricing accuracy; reduced supplier response times from weeks to hours; and provide options with dynamic lead times and quality, cost, certainty – resulting in a quicker and more efficient supply chain process.

Valerie Bednar, MyMaskFit Director, comments: “MyMaskFit is pleased to deliver a programme to the Manufacturing Made Smarter Testbed where we hope to prove the success of sourcing in the regulated digital supply chain marketplace for components of our Reusable and Custom fitted medical grade mask.

As part of this 6-month project, a rapid scale-up of manufacturing operations is planned involving manufacturing partners – including cloud collaboration tools from design and manufacturing software company Autodesk.

Asif Moghal, Senior Industry Manager, Design and Manufacturing at Autodesk comments: “This is another great example of how the industry is coming together and rising to a new challenge. Protecting our key workers is essential and we have an opportunity to bring about new learnings from this rapid development project featuring personalised masks. We are confident this will be a transformative step for the industry, with the potential to scale globally and pass learnings onto other industries.”

The project is funded by the ISCF Manufacturing Made Smarter programme and will conclude in May 2021. Industrial partners also include Plyable, Amplyfi, AI Idea Factory, PXL ICE, Carapace, Cadarn and Industry Wales.

The IMPACT operation is part-funded by the European Regional Development Fund through the Welsh Government and Swansea University.

ENDS

For further information please contact:

Alice Scott

Media Relations Manager - Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG helped keep Tetley tea on shelves during the first wave of the COVID-19 pandemic

As the UK entered lockdown as a result of the Covid-19 pandemic, panic buying of essential items including tea caused a massive spike in demand. With demand for products doubling in some instances, many companies struggled to keep up with supply, but Tata Consumer Products Ltd (TCPL), the parent of the Tetley tea brand in the UK, Eight O Clock Coffee in the USA and Tata Tea in India, managed to keep products on shelves and customers supplied with the tea they needed.

To ensure that it could maintain supplies of tea Tetley’s UK factory in Teesside increased production by more than 40%. Their ability to adapt and respond to the unprecedented level demand owed much to their supply chain strategy on which WMG, University of Warwick had been working with them to enhance since 2015.

Professor Jan Godsell from WMG led the team that analysed Tetley’s sales and stock data to create a demand profile. Professor Jan Godsell explains: “We identified an optimal level of utilisation that would keep TCL competitive and allow spare capacity to deal with fluctuations in demand. John Burdett, Global Operations Director for Tata Consumer Products Ltd, then used these recommendations to help set-up the supply chain strategy, which was rigorously tested during the COVID-19 pandemic as the demand for tea soared.

“It was both an exhilarating time and a frightening time. Because of the buffer management approach we had in place, we were able to deliver 35% surge capacity to supply our customers and consumers and keep the UK drinking tea. This meant we could react extremely quickly to the rapidly moving market conditions and gain competitive advantage.”

TCPL demonstrated how having a flexible supply chain can be used to react quickly to the market and enhance market performance, being able to respond to increased demand and maintain supplies of tea resulted in Tetley gaining market share during the Covid-19 panic buying period.

Through two Innovate UK grants, WMG also helped to develop SupplyVue analytics software. SupplyVue can assess a business’s end-to-end supply chain including production scheduling, planning and inventory management to suggest ways to optimise the supply chain. TCPL made the bold move to deploy SupplyVue just as the COVID-19 pandemic was reaching its initial peak, helping them to reconfigure their tea supply to Canada. When there are increasing levels of volatility along the supply chain, a phenomenon known as the ‘bullwhip effect’ occurs and this took place during the pandemic. It occurs when orders received from a customer are rounded up to suit production constraints resulting in a mismatch in stock levels compared with what is actually required.

John comments: “The end to end visibility that we have as a result of SupplyVue means we’ve eliminated the bullwhip effect – we saw no increased stock levels as we recovered from the panic buying phase of pandemic. Enabled by insight through analytics, we’re now collaborating across the supply chain and are using the end-to-end visibility to get a smooth, even flow of products through to our customers.”

TCPL are now looking at rolling out the same optimisation model into other supply chains and unlocking more value.

Professor Godsell comments: “As humans, we are subject to myopic loss aversion. This is a bias that means we tend to fear loss more than gain. In supply chains, it means that the fear of losing a sale, leads to a change in the production schedule that can lead to overproduction. COVID-19 exacerbated this effect.

“SupplyVue provided full end-to-end supply chain visibility, and the confidence to trust the current plan. This enabled customer orders to be fulfilled at lowest possible supply chain cost and the unnecessary costs of overproduction and excess inventory to be avoided.”

ENDS

2 NOVEMBER 2020

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/january2019/jangodsell250.jpg

Caption: Professor Jan Godsell, from WMG at the University of Warwick

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/lifestyle_tetley_shot_-_new_pack.png

Caption: A pack of Tetley tea.

Credit: Tetley UK

Studies available to view at:

https://warwick.ac.uk/fac/sci/wmg/research/transformation/supply_chain/wmg_tetley_success_story_buffer_theory.pdf

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Manufacturers leverage supply chain practices developed in response to COVID-19 to prepare for Brexit

The COVID-19 pandemic has affected many people across the world, one particular way includes supply chains, with some people finding they couldn’t buy essentials such as pasta or loo roll, and manufacturers had to suddenly change their strategies to ensure their supply chain during the pandemic.

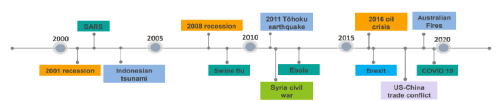

There have been many challenges in the past for the manufacturing supply chain, such as the 2001 recession, SARS, 2011 Tohoku earthquake, 2016 oil crisis, and Brexit. Although there have been other pandemics such as swine flu and Ebola, the COVID-19 pandemic was nothing the modern world had ever seen before.

A survey by researchers at WMG, University of Warwick saw 249 medium to large manufacturers from food and beverage to automotive, and pharmaceuticals to electronic equipment and more industries respond to the survey about their supply chain resilience in the current state and future potential.

They found several impacts from the COVID-19 pandemic, including:

· 58% of firms are still experiencing a decrease in demand 3 months post lockdown

· 66-73% of firms have been effective to responding to increases and decreases in demand

· Buffer management, multi-sourcing and visibility were favoured over agile production networks

· Cash management and securing supply were critical initial responses to the Covid-19 crisis

· 84% of firms found their planning systems were effective, but still required human intervention

· The most apparent bottlenecks to their supply chain were people issues, such as warehouse staff being in quarantine at home

The researchers then assessed manufacturers supply chain resilience during three different times: business as normal, during COVID-19 and preparation for Brexit. For each time period they identified how 6 supply chain resilience practices that could be used proactively (pre-disruption), reactively (during and post disruption) or both. These included:

1. Supply chain planning – demand forecasting and contingency planning (Proactive)

2. Visibility – Having access to real time data (Proactive)

3. Collaboration – Working with SC partners to deliver customer value (Proactive & reactive)

4. Buffer management – Utilising inventory and production capacity to enable material flow (Proactive and reactive)

5. Flexibility – Establishing multiple sourcing options (Proactive and reactive)

6. Adaptability – Transforming the SC in responding to dynamic business environment (Reactive)

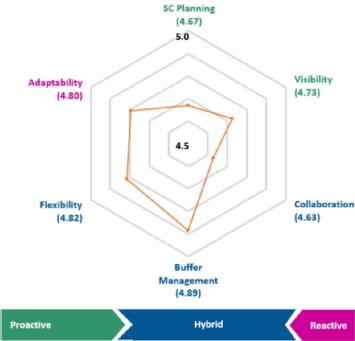

In normal operation firms found their practices to generally be effective. However, there was opportunity for improvements in visibility and collaboration to support improved supply chain planning. Firms also said they have been effective in managing buffers in normal operation.

During the Covid-19 pandemic firms utilised supply chain planning as a response to the pandemic with effective planning systems reported by 84% of manufacturers. However, this still required a high degree of human intervention. Buffer management and flexibility were found to be less effective than in normal operations. The survey found that 55% of manufacturers used inventory as their primary buffer against disruption, with only 32% utilising flexibility within the agile production systems of suppliers. Inventory buffers, whilst effective if the disruption creates an upturn in demand, can be catastrophic to cash flow if demand drops.

Similarly to COVID-19, when it comes to Brexit they’ve found that an increase in collaboration has led to improved supply chain visibility and planning. However, the uncertainty of Brexit is a cause for concern in terms of supply base flexibility with firms unsure of what type of response will be required.

Professor Jan Godsell from WMG, University of Warwick comments:

“It’s interesting to see that the lessons manufacturers have learnt in developing supply chain resilience practices in response to COVID-19 pandemic are helping manufacturers to prepare for Brexit. However, the uncertainty of Brexit, particularly in terms of the impact of flow of material is challenging for developing supply base flexibility. Whilst manufacturers can proactively prepare for Brexit, a high degree of adaptability will be required to buffer against the unknown.

“All manufacturers should consider assessing their current level of supply chain resilience to identify the areas in which their current supply chain resilience practices could be developed. Working collaboratively with supply chain partners to improve supply chain visibility and planning are the key building blocks. More effective use of inventory and capacity buffers, and flexibility within the supply base can further improve resilience. Some disruptions cannot be predicted, and supply chains need to the capability to adapt.”

A circular economy could save the world’s economy post-COVID-19

· The Covid-19 pandemic has challenged all facets of human endeavours, and seven months later the economic effects are particularly being felt

· How the world can leverage the positive and negative effects of COVID-19 to build a new, more resilient and low-carbon economy has been analysed by a group of academics led by WMG, University of Warwick

· A more sustainable model based on circular economy framework could help the world recover financially from COVID-19, whilst facilitating the attainment of net zero carbon goals

The World’s economy is feeling the effects of the COVID-19 pandemic with many industries under threat. A group of researchers from the UK, Malaysia, Nigeria, UAE and Japan, led by WMG, University of Warwick have concluded that adopting circular economy strategies would be the best way for the world’s economy to recover, whilst enabling the transition to a low-carbon economy.

The World Health Organisation declared the COVID-19 pandemic on the 11th March 2020, which saw global supply chains severely disrupted and strained, and the financial market unsettled, resulting in a cross-border economic disaster. Lockdowns and border closures shattered the core sustaining pillars of modern world economies, with the economic shock due to these measures still being weighed across the globe.

In the paper, ‘A critical analysis of the impacts of COVID-19 on the global economy and ecosystems and opportunities for circular economy strategies’, published in the journal Resources, Conservation & Recycling sees a group of researchers led by WMG, at the University of Warwick, critically analysed the negative and positive impacts of the pandemic. To make the world resilient post-COVID-19, the adoption of circular economy framework is recommended for all sectors.

The pandemic had many effects on everyone’s lives, from not leaving the house, being infected and possibly hospitalised, and even losing a loved one. It has had a strain on those who were furloughed or even lost their jobs, and the mental health of the populace. Economically, the effects can be felt everywhere due to the colossal financial loss across both the macro and micro levels of the economy, including the global supply chains and international trade, tourism and aviation and many other sectors, hampering the attainment of the United Nations Sustainable Development Goals. However, the pandemic has provoked some natural changes in behaviour and attitudes with positive influences on human health and the planet including:

· Improvements of air quality, in fact in the UK it’s thought more lives have been saved by the reduced air pollutants compared to the number of people who died with COVID-19 in China, for example.

· Reduction in environmental noise and traffic congestions has led to an increase in the number of people exercising outside to enjoy the atmosphere.

· Less tourism induced by the pandemic, resulting in less exploitation of the beaches, leading to increased cleanliness.

· Decline in global primary energy use. For instance coal use was down 8%, 60% less oil, and electricity plummeted by 20% compared to the first quarter of 2019, leading to record low global CO2 emissions.

· Triggering the need for diversification and circularity of supply chains, and evinced the power of public policy for tackling urgent socio-economic crises.

The researchers have examined the impacts of the pandemic and its interplay with circular economy, to evaluate how it could be embraced to rebuild the world’s economy.

Dr Taofeeq Ibn-Mohammed, from WMG, University of Warwick comments:

“The pandemic has highlighted the environmental folly of ‘extract, produce, use and dump’ economic model of material and energy flows, however the short term resolutions to cope with pandemic will not be sustainable in the long-run, as they do not reflect improvements in economic structures of the global economy.

“We therefore propose circular economy adoptions for all industries, with different strategies for each one. For example, embracing the transformative capabilities of digital technologies for supply chain resilience by leveraging: big data analytics for streamlining supplier selection processes; cloud computing to facilitate and manage supplier relationships; and Internet of Things for enhancing logistics and shipping processes.

“The post-COVID-19 investments needed to accelerate towards more resilient, low carbon and circular economies should also be integrated into the stimulus packages for economic recovery being promised by governments, since the shortcomings in the dominant linear economic model are now recognised and the gaps to be closed are known.”

New study provides insights into how retailers have responded to COVID-19

· The study by WMG, University of Warwick and Blue Yonder examines how retailers have responded to the COVID-19 pandemic to ensure their survival

· The report highlights many points, particularly the need for human intervention as existing processes couldn’t keep up with changes in the markets

· Going forward future systems will need to be more robust and responsive, to increase speed and agility in the supply chain

The COVID-19 pandemic has changed the retail sector, a new study by WMG, University of Warwick, and Blue Yonder has examined how retailers have responded to the situation. The study identified the human vulnerabilities across the supply chain and the need for future investment in flexibility, visibility and automation to improve future resilience.

has examined how retailers have responded to the situation. The study identified the human vulnerabilities across the supply chain and the need for future investment in flexibility, visibility and automation to improve future resilience.

Retailers have faced multiple challenges during the COVID-19 pandemic. Retailers have experienced a combination of unprecedented demand for some particular products whilst no demand for others. Many stores have been forced to close, or adapt their operations to accommodate social distancing. Where possible, there has been a shift to online shopping, but this is not always possible and presents its own operational challenges.

The study gathered insights from 105 different retailers from Europe, Asia and the Americas who offered a glimpse into their survival and navigation of the COVID-19 crisis.

their survival and navigation of the COVID-19 crisis.

The study found that:

· The majority (61%) of retailers used inventory to buffer against the disruption of COVID-19. Supply chain processes and systems were effective, but more than half (58%) of retailers said a high degree of manual intervention was required to respond to the fluctuation in demand and supply.

· Workforce issues were dominant issues for retailers with 59% of warehouse and 48% store operatives being affected by quarantine or illness. This often resulted in the closure of online operations and the need to recruit temporary staff.

· Retailers were polarised in their treatment of supplier payments, with 37% delaying payments and 30% making early payments.

Jan Godsell, Professor of Operations and Supply Chain Strategy at WMG, University of Warwick, comments:

“Using inventory to buffer against the disruption of COVID-19 was the most common strategy deployed by retailers. This provides the greatest certainty of supply but comes at a cost. In contrast, only just over a quarter (29%) of retailers relied on suppliers with more agile manufacturing and distribution networks, which is a potentially more resource efficient and resilient response.

“With 75 to 80% of products seeing a demand fluctuation, retailers were slightly better at responding to decreases rather than increases in demand. Whilst retailers found that their supply chain processes and systems to be effective in responding to the demand fluctuations, many were still dependent on the human touch.

“From warehouse and store operatives being affected by quarantine or illness to an over-dependence on human intervention within supply chain planning, COVID-19 has highlighted the human vulnerabilities across retail supply chains.”

Wayne Snyder, Vice President Retail Strategy, EMEA at Blue Yonder, comments:

“Early indications in Asia show that customers have been most supportive of those retailers they deemed to have responded best to the crisis and we’d expect that pattern to follow across Europe and the US. A critical learning for retailers is the need to invest in creating supply chains with greater flexibility, visibility and automation. Here technologies such as artificial intelligence and machine learning will play a key role in helping retailers navigate future disruption, whilst still meeting customers’ expectations.”

The survey was administered on-line by Qualtrics in late April 2020. It was targeted at senior executives in retail supply chains, in Europe, Asia and the Americas. 105 responses were received with relatively equal distribution across the regions.

High-res images are available at:

https://warwick.ac.uk/services/communications/medialibrary/images/april2014/head_08.jpg

Professor Jan Godsell, WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/june2020/covid_graph_1.png

Caption: Bar chart displaying what new actions have been taken by retailers in response to the covid-19 crisis. Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/june2020/covid_graph_2.png

Caption: Bar chart displaying what has proven to be retailer’s most effective strategy for supply chains when dealing with the Covid-19 pandemic. Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/june2020/covid_graph_3.png Caption: Graph showing what change in demand retailer’s supply has experienced. Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/june2020/covid_graph_4.png

Caption: Bar Chart displaying the bottlenecks retailers have experienced in the supply chain. Credit: WMG, University of Warwick

Why we need to stop panic buying – expert comment from Professor Jan Godsell

Pictures of empty supermarket shelves, and stories of supermarkets putting limits on items dominates the news as people stockpile due to Coronavirus.

Pictures of empty supermarket shelves, and stories of supermarkets putting limits on items dominates the news as people stockpile due to Coronavirus.

Jan Godsell, Professor of Operations and Supply Chain Strategy at WMG, University of Warwick offers her expert comment on why it needs to stop.

Supporting the supermarkets to ‘smooth the spike’

"The current issues facing UK grocery supply chains, is not one of supply, but one of demand. The UK grocery retailers have sophisticated planning systems that seek to balance demand and supply. Over time, they learn seasonal patterns, the impact of promotions and other events and automatically adjust. The systems are so sophisticated that in the shorter term, they can adjust to changes in weather, for instance making sure we have the right food for our BBQs on hot days.

Need to smooth out the spike…

"The one type of demand that these systems really don’t like is unpredicted spikes in demand. Most grocery products have a relatively stable, and predictable rate of demand that the retailers can plan for. If this suddenly increases, it can take time for the supply chain to react, and move the stock that is further upstream to the shelf.

The problem at the moment is that whilst there is stock upstream in the supply chain, it is hard for the retailers to replenish it to shelf at the rate consumers are taking it. It also means that rather having stock in a warehouse, that could be used by all, the stock gets isolated in our homes, where it can only benefit an individual or their family.

Grocery retailers are taking the really sensible step of ‘rationing’ to try and smooth out these spikes. This is a really responsible reaction, and one to be commended as it will help to ensure that everyone gets the essential items they need.

Need to protect the vulnerable…

"Many in the UK have to budget carefully and only have the financial resources to buy what they need, when they need it. They can’t afford to stock pile.

Rationing should improve availability of products to all, and encourage everyone to buy at the rate that they consume. In that way we should all have access to the essential items we need.

Further measures by grocery retailers to prioritise delivery slots, and have dedicated in-store shopping slots for the elderly and vulnerable are be commended too.

What else could be done?

"Whilst UK retailers have started rationing, some are still offering promotions. Buy-one-get one-free, 3 for 2, or buy 2 for a fixed amount, all encourage consumers to buy more than they actually need.

Perhaps now is the time to stop such promotions, move to fixed pricing, to discourage purchasing more than required.

The Italian retailers are a number of weeks ahead of the UK retailers in understanding the impact of the virus on demand. It would be expected that once initial panic buying is over, when cupboards are full, replenishment will return to a more normal rate. There may be some uplift as we stay at home, and consume more in our domestic environment. Insight from the Italians, shared with UK retailers and their suppliers could help us to prepare.

With more consumers shopping online, and rationing in place, donations to food banks have fallen at a time when they are needed more than ever. Perhaps it is time to consider, how we can move food banks on-line too. Donate food, as part of our on-line shop or as a direct donation. With digital food bank vouchers, enabling the most vulnerable to get direct supply from a retailer.

These are unprecedented times. The basic principle of good supply chain management is to balance demand and supply. The UK retailers are working really hard to ensure that we have all the essential items that we need. We can help too, by buying responsibly and supporting the more vulnerable."