WMG News

Student recruited by West Midlands SME following success of WMG Internship Programme

It’s been a really challenging year for many businesses, so the WMG Internship Programme, launched this year, came as welcome news to many.

It’s been a really challenging year for many businesses, so the WMG Internship Programme, launched this year, came as welcome news to many.

The Programme is designed to allow companies and students to work together to overcome a business challenge or investigate ways of improving business performance. Interns, placed at companies, are supervised by an expert member of the WMG team to ensure objectives are met and to provide access to world-renown facilities. This means participating companies get the benefit of both the resources and industry-leading knowledge.

Tom Lockhart, WMG SME Project Officer, explains: “Over the past 10 years, we have supported more than 300 internship projects. We work with businesses to identify their challenges, scope out a project and set clear objectives for a short, but focused piece of work.”

One particular highlight of this year’s programme was an internship placement at Alucast, an aluminium casting foundry that supply the automotive industry.

Through a collaborative approach, the student intern, Farhan, was, within just 12 weeks, able to help boost productivity by an impressive 30% and has now been offered a full time position. This is a particularly positive outcome in such challenging times and a real testament to Farhan’s hard work.

John Swift, Managing Director at Alucast, commented: “We have long been an advocate of promoting engineering as a career choice and, with this in mind, it was great to work with Farhan. It reinforced our belief that young students and graduates make excellent employees, combining a great work ethic with technical knowledge and insight. The project really exceeded expectations and we’re pleased to be able to offer Farhan a full-time role with us.”

Read more about the SME Team’s project with Alucast, an aluminium casting company based in the Black Country and more success stories here: warwick.ac.uk/smesuccessstories

To find out more about working with the WMG SME Internship Team email wmgsme@warwick.ac.uk

WMG one of three major Midlands industry partners in new alliance

Three of the major industry partners in the region are to work closer together for the good of the local economy as part of a new 12-month pilot.

WMG, at the University of Warwick, The Coventry and Warwickshire Local Enterprise Partnership (CWLEP) Growth Hub, and The Manufacturing Technology Centre have signed a new agreement which will make it easier for manufacturers to access equipment and expertise they need to develop new and existing products and processes.

The three organisations will form a working party meeting weekly to co-ordinate areas of common working, ensure that initiatives are shared across the three organisations, and look at joint campaigns.

The partners will focus on manufacturing and engineering companies across the CWLEP area, and the new alliance will work closely with other partners such as the West Midlands Combined Authority, the Coventry and Warwickshire Chamber of Commerce and the Federation of Small Businesses.

Mark Swift, Head of SME Programmes at WMG, University of Warwick said: “The agreement will help manufacturing unlock the opportunities presented by green manufacturing, digitalisation and the journey to Net Zero transport. Coventry and Warwickshire already has very strong partnerships and we believe the work of WMG and the MTC combined with the extensive network and market intelligent of the Coventry and Warwickshire LEP will form a powerful offer to local companies.”

by green manufacturing, digitalisation and the journey to Net Zero transport. Coventry and Warwickshire already has very strong partnerships and we believe the work of WMG and the MTC combined with the extensive network and market intelligent of the Coventry and Warwickshire LEP will form a powerful offer to local companies.”

Craig Humphrey, Managing Director of the CWLEP Growth Hub, said: “The three organisations had worked with each other in the past but the pilot would make the collaboration far more effective.

“The three organisations know each other well and collaborate when the need arises, but we have a tremendous amount of common ground and market intelligence which we all felt would be more powerful and useful to local companies if it was harnessed effectively and the formation of the working party is the first stage in that.”

The working party will be overseen by a senior management team which will review its effectiveness on a monthly basis.

Clive Hickman, the founder and Chief Executive of the MTC, said: “We work right across the UK, but are based in Coventry and Warwickshire which is internationally recognised as a centre of excellence for manufacturing and engineering, and believe that we always have more to offer in terms of support to local companies.

“The three organisations are ideally placed in slightly different areas of the market to bring unique advantages to what could be a very powerful alliance.”

ENDS

21 JANUARY 2021

NOTES TO EDITORS

About WMG, University of Warwick

WMG is an academic department at the University of Warwick and is the leading international role model for successful collaboration between academia and the public and private sectors, driving innovation in science, technology and engineering. They are a founding partner of the HVM Catapult, and are one of seven centres within this government initiative.

About the CWLEP Growth Hub

The CWLEP Growth Hub was founded to help companies across the region access support and help in a range of areas and has now helped create more than 5,000 jobs across Coventry and Warwickshire.

About the MTC

The MTC was established in 2010 with the objective of bridging the gap between academia and industry and employs more than 700 staff across three centres – two of which are at Ansty Park, near Coventry.

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG partners with Pashley Cycles and a team of UK SMEs to bring a novel e-assisted cargo trike to market

WMG is collaborating with Pashley Cycles and three other SMEs across the Midlands to develop an electrically assisted, last mile delivery trike. The trike features an innovative tilting suspension system which will provide greater stability on corners (and therefore speed and manoeuvrability) than a conventional tricycle configuration of the same size.

Supported and part-funded by the Niche Vehicle Network, through a “Production Readiness” funding call, the Articulating Lightweight Electrically-assisted Cargo Solution (ALECS) project, will form the platform for a new generation of configurable products to meet the rapidly growing market for zero-emission last mile cargo vehicles.

Project Manager, Dr Alex Attridge, explained: “This project provides a fantastic opportunity for WMG to apply its knowledge and expertise in vehicle electrification, and in product testing and evaluation, to a real-world product development process, helping a consortium of UK SMEs bring a new, zero-emission delivery vehicle to a rapidly growing market.”

ALECS is designed to carry cargo on a versatile and customer configurable, multi-functional rear platform. It is particularly suited to parcel and package deliveries in an urban environment where fast and efficient multiple deliveries are the key to success.

The consortium brings together the engineering and simulation capabilities of Simpact Engineering, with the high strength, lightweight tubing expertise of Reynolds Technologies, and the composite panelling and cargo structures expertise of Foresight Innovations. Coupled with Pashley’s heritage and capability in the personal mobility, mobility as a service, and cargo cycles markets, and WMG’s knowledge and experience in progressing innovation through the TRL levels into finish products, the project is set to be completed in April 2021.

One of the seven High Value Manufacturing Catapult centres, WMG brings a number of key technical capabilities to the project. These specifically include the development of photorealistic visualisations (in the form of still renders and interactive digital models) of the concept, and the delivery of digital design review content for both desktop and virtual reality environments. WMG is also responsible for the modelling and optimisation of the production facilities in an immersive, digital environment, utilising large scale laser scanning technology and the latest game engine software. Finally, as the consortium begins the physical testing stage, we will be responsible for the instrumentation of prototype and pre-production vehicles, and the subsequent data acquisition and analysis.

Managing Director at Pashley Cycles, Adrian Williams added: “Working with WMG has given Pashley the opportunity to take advantage of skills, expertise and facilities which we would never otherwise have had access to. This is really helping us create a robust and reliable, yet lightweight product which we’re confident will give us a competitive advantage in the market.”

Managing Director at Pashley Cycles, Adrian Williams added: “Working with WMG has given Pashley the opportunity to take advantage of skills, expertise and facilities which we would never otherwise have had access to. This is really helping us create a robust and reliable, yet lightweight product which we’re confident will give us a competitive advantage in the market.”

£6 million programme extension to help small manufacturers across the Midlands

· The SME Group at WMG, University of Warwick, has secured a £6m extension to their programme to help small manufacturing companies in the East and West Midlands

· Funded by the European Regional Development Fund (ERDF) and the High Value Manufacturing Catapult at WMG, to create a much-needed support for Midlands manufacturers

· The programme will work collaboratively with a further 250 manufacturing companies across the Midlands to solve manufacturing challenges, to improve productivity and boost competitiveness

· Support is provided from a dedicated and highly industry experienced team with expertise in materials and manufacturing, sustainability, digital manufacturing and business transformation

The programme delivered by the SME Group at WMG, University of Warwick has been a major success in the West Midlands over the last 2 years, helping over 100  companies, develop 71 new products and processes, from automation and productivity plans through to the zero emission technologies of tomorrow.

companies, develop 71 new products and processes, from automation and productivity plans through to the zero emission technologies of tomorrow.

Companies, including Genius Facades, a construction company in Wolverhampton, who gained a 15% increase in productivity, thanks to the team helping them by digitising their factory floor.

Another example includes the team helping Power Panels Electrical, in Walsall, win £3m of contracts in the Niche Vehicles sector.

Given the success of the programme, the team have been awarded a further £6m from to take them through to March 2023, meaning the team has gone from a 2 year £5m programme, to an £11m 5 ½ year programme. This extension will enable the team to operate from Wolverhampton and Worcestershire in the West, to Loughborough and Luton in the East Midlands.

Over the next 2 ½ years they will help more than 350 SMEs benefit from the latest in digital manufacturing technologies and thinking, helping them become more productive, competitive and sustainable. Fully funded support from 2 to 15 days is available for eligible small manufacturers.

Dr Mark Swift, head small business programmes at WMG, University of Warwick comments:

“We are thrilled to have the manufacturing competitiveness programme extended, and look forward to being able to help hundreds of small businesses across the midlands to transform their business and become more sustainable.

“The support we offer will be especially helpful in light of Covid-19, as after months of lockdown businesses can be helped to get back on their feet and thrive.”

“We are here, ready to help our region’s manufacturing companies; to make manufacturing technology and thinking work for you, to help our businesses to grow become more productive and sustainable and ultimately make more in the UK.”

If you are a local manufacturing company please get in touch, the team would love to hear from you. E-mail them at: wmgsme@warwick.ac.uk

ENDS

9 SEPTEMBER 2020

NOTES TO EDITORS

High-res images available at:

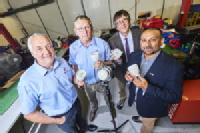

Caption: The WMG SME team improve the shop floor productivity at Genius Facades

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG welcomes Deputy CEO of NatWest Holdings

WMG was delighted to welcome Alison Rose, Deputy CEO of NatWest Holdings, to a special SME event at the Professor Lord Bhattacharyya Building at the University of Warwick.

WMG was delighted to welcome Alison Rose, Deputy CEO of NatWest Holdings, to a special SME event at the Professor Lord Bhattacharyya Building at the University of Warwick.

Alison, and her colleague Richard Hill, Head of Automotive and Manufacturing at NatWest, joined CEO of WMG Centre High Value Manufacturing Catapult, Archie MacPherson to meet with a series of SMEs that NatWest and WMG are currently supporting on the ‘Create Test Launch’ (CTL) Programme.

The CTL Programme was launched in 2017, with WMG experts providing hands on advice and support with new product development.

The potential of the Programme was recognised by NatWest, who then partnered with WMG to subsidise ten clients through CTL.

At the event Alison, described as ‘the most influential woman in investment banking’, spoke with passion about the need to prioritise innovation in the boardroom and sparked a lively discussion. Key topics included the challenges of balancing operational pressures against the desire to innovate, the crucial role of good leadership, understanding the innovation process, and support for SMEs in an uncertain political and economic climate.

With 50,000 manufacturing clients nationally, NatWest is keen to promote innovation and leadership in industry. Following the visit, WMG will continue to work closely with NatWest to strengthen the UK manufacturing sector.

Midlands based global doyens of darkness are LED into daylight

Tipton-based darkroom specialists Paterson Photographic Ltd have added daylight to darkness in their leading studio and theatre lighting equipment, thanks to LED technology support from WMG at the University of Warwick.

Tipton-based darkroom specialists Paterson Photographic Ltd have added daylight to darkness in their leading studio and theatre lighting equipment, thanks to LED technology support from WMG at the University of Warwick.

Having developed a global reputation for the quality of their darkroom equipment, they wanted to add to their product offering and re-enter the studio lighting market with a comprehensive range of Continuous Lighting units manufactured in their own UK factory.

Creating a studio lighting range that used LEDs with a colour temperature of 6000K (daylight) rather than the most common methods using fluorescent lighting would provide Paterson Photographic with a technological leap in their products.

The SME (Small and Medium Sized Enterprises) support team at WMG at the University of Warwick provided technical and research support allowing the company to launch the first batch of LED-based daylight products with bespoke coloured filters at the 2018 Photography Show at Birmingham’s NEC. The new products are expected to generate sales in six figures for Paterson over the next year.

Lamppost EV charging points brought to market thanks to WMG

Lampposts could be the answer to electric vehicle charging, thanks to help from researchers at WMG, University of Warwick in bringing a new brand of charging points to market – some of which are powering electric vehicles on the University campus.

Startup company char.gy created a new electric vehicle charging point product – which can be easily installed onto existing lampposts, resulting in no requirement to add another power supply or dig up the road or pathway – but it required a bespoke electronic circuit board in order for it to meet to EU standards for public charge points.

The SME support team at WMG helped char.gy rapidly design, build and test a prototype of the new electronics board in order to achieve the certification deadlines.

Because of this, char.gy was able to complete the product to time, and send it for testing – eventually making the charge points ready for public use.

The University of Warwick not only supported the development of char.gy, but has also purchased “char.gys” to charge electric vehicles across the campus – including the University Estates Team’s new fleet of battery-powered Nissan vans.

WMG data specialists helps streamline production at Warwickshire brewer

Purity Brewing Ltd is a small brewer based on a farm between Studley and Great Alne not far from Stratford upon Avon. Sales continue to boom, which means constantly balancing the production of their beers with growing customer demand. The company turned to the SME team in WMG at the University of Warwick to help develop data systems to manage this complex operation while they get on with brewing the beer.

Purity Brewing Ltd is a small brewer based on a farm between Studley and Great Alne not far from Stratford upon Avon. Sales continue to boom, which means constantly balancing the production of their beers with growing customer demand. The company turned to the SME team in WMG at the University of Warwick to help develop data systems to manage this complex operation while they get on with brewing the beer.

Andrew Thurston, Finance Director at Purity Brewing said:

“The WMG SME Group quickly identified our technical and business challenges. The new production tool will save us money and support Purity with its rapid growth.”

Purity Brewing benefitted from collaborative project support through the WMG SME Group’s Product Innovation Accelerator Project, part-funded by the European Regional Development Fund. This helps manufacturing SMEs within Coventry and Warwickshire and the Black Country are to create, test and develop new products, improve processes and access innovation support.

3D printing helps carve out Christmas treat

A Coventry firm has turned to 3D engineering experts from WMG to help create a new range of unique biscuit treats – Mug Huggers – that sit on the side of a mug.

A Coventry firm has turned to 3D engineering experts from WMG to help create a new range of unique biscuit treats – Mug Huggers – that sit on the side of a mug.

Arden Fine Foods, a Tile Hill-based firm specialising in sweet and savoury bakery products, were keen on producing the creatively shaped biscuit, but to achieve this vision they needed to engineer a unique shape to cut the biscuit dough.

The challenge required employing a flexible process that could easily be altered when minor shape changes were needed – allowing for design freedom and efficient tool manufacture.

WMG researchers used 3D printing, design and additive layer manufacturing capabilities, to help explore new designs and create dough cutters that were used to trial a number of different biscuit shapes, allowing the company to achieve the perfect shape before investing in a drum to fit onto the dough-depositing machine.

WMG technology helps Midlands cycle company create next generation bicycles for Transport for London

Engineers from WMG, at the University of Warwick, are providing advanced technology support for Stratford-Upon-Avon’s Pashley Cycles, England’s longest established bicycle manufacturer based in who, with Serco, who this week won the contract to supply the next generation of bicycles for the Transport for London (TfL) Cycle Hire Scheme.

Engineers from WMG, at the University of Warwick, are providing advanced technology support for Stratford-Upon-Avon’s Pashley Cycles, England’s longest established bicycle manufacturer based in who, with Serco, who this week won the contract to supply the next generation of bicycles for the Transport for London (TfL) Cycle Hire Scheme.

Under the new contract Serco will introduce bicycles, made by Pashley, with the first ones available at the start of October 2017. The new bicycles, which will be produced in the company’s home town of Stratford-Upon-Avon, used WMG’s technical support and advice to help create cycles that are 10% lighter than the current model and that are designed to give a more manoeuvrable and comfortable riding experience.

Through the WMG centre High Value Manufacturing Catapult, based at the University of Warwick, and renowned for its expertise in light weighting, the WMG SME Group provided “additive layer manufacturing” and 3D printing assistance to enable Pashley to develop the new bicycle. This support played a significant part in creating the bike prototype, which in turn helped secure the TfL contract.