WMG Insights

Rapid prototyping through soft-tooling and micro-injection moulding

New Product introduction (NPI) can be a demanding and costly process since significant time and labour needs to be dedicated to make a successful leap in the market. Injection and micro-injection moulding are common manufacturing techniques for NPI in a wide range of sectors, including medical devices and optics for manufacturing complex and net-shaped miniaturised plastic components. However, the product development stage usually requires multiple design iterations, especially in high-value markets such as medical devices. The modifications of injection mould tools are generally very costly and hinders the entrance of many bright new ideas into the market, particularly for SMEs.

Engineers at WMG Centre for Imaging, Metrology and Additive Technologies (CiMAT) have developed a rapid prototyping process that can help SMEs to develop their products through 3D printed (Additively Manufactured - AM) injection mould tools. Several AM techniques have been proven for making mould inserts and product iterations at minimal cost, in low batch volumes. CiMAT has a full range of AM capabilities for realising prototype moulds, and a real-time monitored micro-injection moulding capability for addressing SMEs needs in low volume, high quality manufacturing.

Currently, a wide-range of demonstrator products have been developed within the High Value Manufacturing Catapult funded project including medical device prototypes and micro-mechanical components (see Fig.1). The prototyping service that WMG offers starts with 3D product design and 3D printed mould making which provides significant flexibility as per customer demand. The printed moulds are then integrated in a mould assembly for manufacturing and prototyping runs using micro-injection moulding technology. Prototypes made from commodity or medical grade thermoplastic materials are then ready for the customer to assess and evaluate the next stage of the product development.

Fig.1 Demonstrator products developed using the soft-tooled rapid prototyping process: a) A micro gear and mould for mechanical applications, b) a demonstrator micro-fluidic chip, c) micro-tensile bar for materials and process characterisation, d) components for the cell-viability studies of rapid-prototype products.

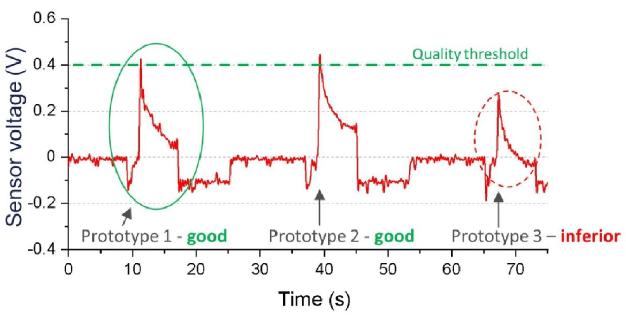

The team is also exploring the research aspect of soft-tooling and implementation of data-rich process monitoring methods using integrated sensors on the micro-injection moulding machines (see Fig.2). Investments and research in this area will increase the overall quality of the prototypes being made and eventually provide an accelerated product development for high-added value products.

Fig.2 In-line pressure monitoring of micro-injection moulding process for inferior quality detection of rapid prototypes.

The team are looking forward to collaborating with and supporting SMEs to use this soft-tooled rapid prototyping for product development. WMG’s extensive skill set on 3D design, additive manufacture, and micro-injection moulding can accelerate the product development stage significantly. The research aspect of the project is also significant, where companies are welcome to join with WMG in Collaborative Research & Development projects.

For further information about this area of research, or to explore working with WMG, please contact:

Dr Mert Gulcur, mert.gulcur@warwick.ac.uk

Dr Greg Gibbons, g.j.gibbons@warwick.ac.uk

Dr Vannessa Goodship, v.goodship@warwick.ac.uk