WMG News

WMG and Senergy Innovations Ltd launch Graphene Enabled All Polymer Solar Thermal Cell

Solar thermal cells continue to attract much interest as they have massive potential to heat water in a cost-effective and sustainable process. To date, the efficiency of these cells has been limited as the polymers used in their manufacture are poor thermal conductors.

Solar thermal cells continue to attract much interest as they have massive potential to heat water in a cost-effective and sustainable process. To date, the efficiency of these cells has been limited as the polymers used in their manufacture are poor thermal conductors.

However, thanks to funding from BEIS (Department for Business, Energy & Industrial Strategy) a team of researchers led by Professor Tony McNally, from WMG, at the University of Warwick in partnership with Senergy Innovations Ltd have developed the first nanomaterial enabled all polymer solar thermal cell.

The thermal properties of the polymers employed are modified such that heat from sunlight can be transferred with high efficiency to heat water in a cheap and sustainable manner. The modular design of the cells allows for the rapid construction of a solar thermal cell array on both domestic and industry roofing.

The team are now working with a consortium of industry partners focused on manufacturing the solar thermal cells in high volumes.

Dr Greg Gibbons, at WMG, and his team have also produced the first prototype (1:1 scale) of the solar thermal cell fully manufactured by 3D printing. This activity has been transformative in guiding the design and critical aspects of the manufacture of the solar thermal cells.

Professor Tony McNally, Director of the International Institute for Nanocomposite Manufacturing (IINM), at WMG, University of Warwick comments:

“It is really pleasing to see several years of research activity and the understanding gained being translated in to a real world application. Our fundamental  work on the thermal conductivity of 1D and 2D materials, including graphene, and composites of these materials with polymers could revolutionise the supply of affordable, clean and sustainable energy.”

work on the thermal conductivity of 1D and 2D materials, including graphene, and composites of these materials with polymers could revolutionise the supply of affordable, clean and sustainable energy.”

Christine Boyle, CEO, Senergy Innovations Ltd. adds:

“Switching to advanced polymer materials meant a more efficient manufacturing process and more flexible product design. This resulted in the breakthrough of the low cost, low carbon, lightweight smart Senergy panels. Our job now is to ensure that Senergy solar panels become a key part of the smarter built environment and make renewable heating and cooling systems affordable and accessible for everyone.”

ENDS

15 OCTOBER 2020

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/tony_m_solar_cell_testing.jpg

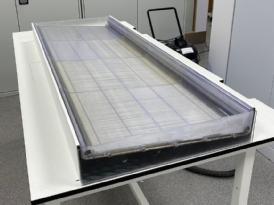

Caption: The solar cell as it went in for testing

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/october_2020/christine_boyle.jpg

Caption: Christine Boyle, CEO of Senergy Ltd with the Solar Panel

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk