Success Story

WMG validates the UK’s fastest 3D Printer as part of their SME support programme

“There is no denying that this printer is “rapid”. Against the competitors we looked at, it is the fastest printer in the UK. Speed wasn’t its only revelation; from the outset it was easy to use with basic engineering knowledge of 3D print functions and deserves the time of all Material Extrusion printer users, from hobby to industrial implementers.”

Neil Jefree, Innovation Manager, WMGLink opens in a new window

Background – Young engineer spots a gap in the 3D printing market

CONSTRUCT3DLink opens in a new window is an innovative new start-up business founded by mother and son team Therese and Jacob Lord.

After receiving a 3D printer for his 18th birthday and finding that it didn’t step up to his requirements, young engineer Jacob Lord decided to take it apart, update it himself and experiment with it, printing hundreds of different items. With a background in physics, mechanical and electrical engineering, as well as a degree in computer games design, Jacob went on to develop his own 3D printer now known as the Construct1 with a Construct1XL model for larger build volume.

The printer has a very sophisticated aesthetic with protected design features. Its speed is what really sets it apart, it can print at a rate of 320mm per second while maintaining quality and high resolution in builds. Key influencers and 3D printing experts[1] have been wowed by its performance and the company have been involved in high-profile videos to showcase the products.

Challenge – How to make an innovative product a commercial reality

CONSTRUCT3D has had a mammoth six-year journey to arrive where it is today. The family trio had taken a highly innovative idea through research and development, prototyping, and market testing.

After a successful project 3D printing headbands for much needed PPE equipment during the Covid pandemic, CONSTRUCT3D were starting to get serious enquiries from individuals and companies wanting to buy their machines. However, to boost credibility and marketing opportunities they required some crucial third-party validation.

They needed to independently verify the speed of the Construct1 and needed help with Electromagnetic Compatibility (EMC) testing which was essential for them to meet market standards and to start selling the products. EMC testing is a critical step in the design and manufacturing processes of electronic devices. There are EMC regulations to ensure reliability and safety.

Solution – Networking is key to unlocking opportunities

At last year’s TCT 3sixty show, CONSTRUCT3D took a stand and were bowled over by the response to the printer. Meeting a range of important voices in the industry, they were introduced to Dr Kylash Makenji, leader of WMG’s support for SMEs in manufacturing technologies. He suggested that WMG carry out the testing the team needed through their funded Digital Innovation for Manufacturing programme, part funded by the EU and the WMG centre High Value Manufacturing Catapult.

Independent trials verify speed and performance

CONSTRUCT3D’s Therese and Jacob brought the printer over to WMG where Neil Jefree, an Additive Layer Manufacturing (ALM) specialist at the department was initially very impressed. He remarks:

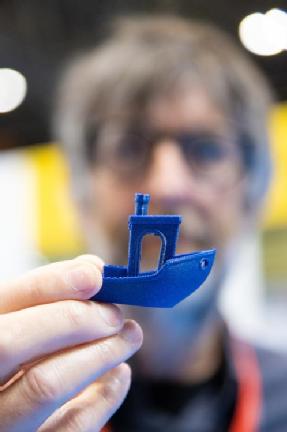

“On the face of it, the printer looked extremely fast, and I was excited to see how it fared against some of the top competitors in the Material Extrusion 3D Printing space[2]. We conducted a product review alongside the current market leaders, printing standardised parts such as “Benchy Boats” which is a known standard for benchmarking printers and capabilities followed by ASTM D638 “Dog Bones”, another standard used for rapidly measuring a material’s tensile strength using time trials and tensile test analysis. We also reviewed the product as a development user and undertook cost comparisons.”

The results were striking:

- The tests showed that the Construct1 was printing one Benchy Boat every 26 minutes and 8 seconds, which is 5 times faster on average than its closest rivals. In terms of accelerations, the machine can print up to 18,000 mm/s^2, 40mm^3/s volumetric melt rate {OR} 40 cubic mm/s flow.*

- It was found that even at such speeds, there was no compromise in terms of the materials’ abilities to be used for their relative applications.

- It was also noted that the velocity and uniform cooling of the print head clearly enabled higher angles to be printed without support, reducing further print time and waste materials. This is an incredibly positive finding in a market that is on a quest to reduce its carbon footprint and create more affordable options for home construction.

Testing covered a wide range of printers, from domestic printers to heavy industry printers, across a price range of £150 - £150,000. The study found extremely impressive results when looking at the strength and quality of parts printed on the Construct1 in comparison with the most expensive heavy industry printers.

With the team happy with the findings, WMG's Dr David Norman went on to conduct the all-important EMC testing using WMG’s EMC lab which would give CONSTRUCT3D the credibility that its product was fit for purpose and safe to use in an industrial setting.

Impact

- Following the EMC testing the Construct1 was safely taken to market and the company secured £25,000 via a successful Kickstarter campaign

- The benchmarking study has allowed CONSTRUCT3D to confidently promote the high speed of the printer and kick start marketing activity on a bigger scale

- The company has gone on to secure a Research and Technology Organisation (RTO) grant to set up their factory and production processes and the printers have now gone into production at the company’s Lincoln based factory

- They are collaborating with WMG’s CiMAT (Centre for Imaging, Metrology and Additive Technologies) to examine the effects of printing filament at speed

- Additional R&D work is also underway looking at the properties of materials printed on the machine which appear to be changing because of the speed of prints, reflecting the properties of materials manufactured using other manufacturing techniques. This could be a fascinating discovery and could provide further benefits of 3D printing in industry

“The work carried out by WMG has helped us take our printers to the next level. Thanks to WMG’s testing, we can now confidently say our printer is exceptional in terms of reliability, useability, and speed; we are reassured and ready to compete on a global level. I also cannot emphasise enough how vital David’s help with the EMC testing was in giving us credibility and ensuring we met all relevant industrial standards.”

Therese Lord, Director, CONSTRUCT3DLink opens in a new window

“It has been great to work on a product with such potential to shake up a market and make 3D printing at speed a cost friendly option for a range of different organisations and individuals.”

David Norman, Technology Transfer Engineer, WMG

*The team have since updated the model which is now printing benchy boats at around 23 minutes, offering further speed without compromising the quality or accuracy

For more information about WMG’s support for SMEs visit:

For more information about WMG’s research capabilities in ALM visit:

https://warwick.ac.uk/wmg/research/materials/alm/about

[1] https://construct-3d.com/about-us/

[2] https://www.sciencedirect.com/topics/engineering/material-extrusion