Success Story

Researchers discover sustainable wastewater treatment technology for hydrogen production

Challenge

Academia and industry have both long been exploring Microbial Electrolysis Cells (MEC), whereby electrogenic microorganisms are used to break down organic pollutants in wastewater, producing clean water and hydrogen gas. Hydrogen itself is a valuable renewable resource, and could be sold to the chemicals and plastics industry, or for use in hydrogen fuels cells for energy storage or electric vehicles.

The technique, while promising, has yet to be deployed at an industrial scale because of the high cost of anode materials, typically graphite or carbon, costing several hundred pounds per square metre, and relatively low rates of hydrogen produced at higher volumes.

Our Sustainable Materials and Manufacturing research team, led by Dr Stuart Coles, has been looking at ways to refine the technique by investigating alternative materials and processing methods.

Solution

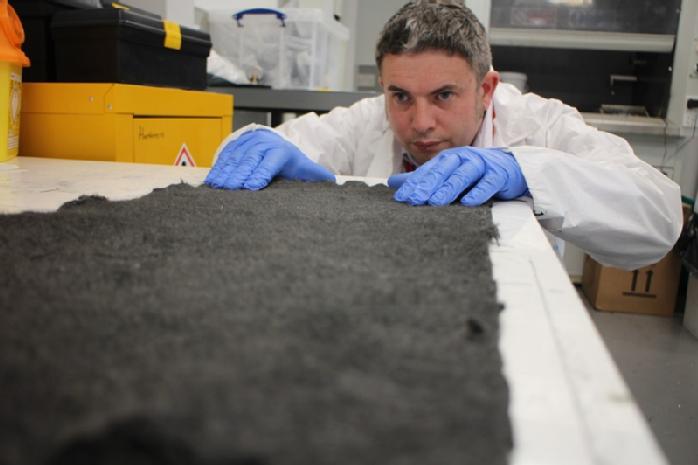

Dr Coles and his team identified a low-cost alternative anode material in the form of recycled carbon fibre mats, using waste materials from the automotive and aerospace industries. The mats cost just £2 per square metre, a fraction of the cost of graphite materials, and early results indicated that they performed even better.

Our researchers first tested the solution at a small scale in the lab using synthetic wastewater. They then made use of facilities at the Life Sciences department at the University of Warwick to test it on a larger scale with real wastewater. They discovered that the bacteria that developed on the recycled carbon fibre anode, had better temperature tolerance and produced considerably more hydrogen than the graphite anode.

After seeing these positive results, we partnered with Severn Trent Water, setting up a pilot system at Minworth water treatment site for three months. The pilot system processed up to 100 litres of wastewater per day and showed outstanding results right away. It removed up to 51% of organic pollutants and up to 100% of the suspended solids from the water whilst producing 18 times more pure hydrogen than the graphite material.

Impact

Considering the improved performance and lower materials cost, our researchers concluded that their new process cost 93% less than a similar system using graphite materials. These findings make a compelling case for the development of larger pilot systems, something which Severn Trent Water plan to do:

Bob Stear, Chief Engineer at Severn Trent said: “The performance boost and cost savings demonstrated from this research mean that MEC technology is one step closer to being cost competitive with existing wastewater treatment assets. WMG have also demonstrated that this technology has the potential to create a more circular wastewater treatment process which will be essential to delivering on our long term sustainability goals and Net Zero plans. We’re currently scoping scaling up the technology at our test-bed plant in Redditch.

He added ‘We really like working with WMG – they have a great mix of academic know-how and desire to deliver practical solutions that can work in the industrial setting’.

This in turn, could encourage others in the industry to follow suit, opening opportunities for the wastewater treatment industry to become more sustainable, in line with the Government’s net zero agenda.

Dr Coles said, “We are really excited about this technology. By taking waste from the automotive and aerospace sectors, we have developed a circular solution to a longstanding problem. Instead of just treating the wastewater, we are now able to extract value from it in the form of hydrogen at a lower cost than ever before. The next phase of this work is look at optimising the design of the microbial electrolysis cells and further reduce the level of pollutants in the water. This in turn should help produce even more hydrogen!”

For more information about working with WMG, please email wmgbusiness@warwick.ac.uk.