Success Story

New lab ‘must-have’ wireless sensor stirs up new opportunities for data collection

Challenge

Manufacturing novel advanced materials, polymers, and medicines push innovation forward and help to solve problems of health, pollution, security, and clean energy. The discovery of innovative products often requires a vision backed up with months and years of routine work. The human is crucial in generating the vision; but the human factor can cause errors, irreproducibility, and side-track the discovery in routine work. The past pandemic and lockdown have delayed innovation and laboratory research. A slowing economy decreases R&D investment, which further puts downward pressure on future economic growth and risks undermining the UK's leading position in materials discovery and innovation.

Monitoring of process parameters is a necessary part of modern production systems, mechanical engineering and science. With the increasing complexity of processes in today's industry, information gathering, and data acquisition can also become more complex using multiple instruments, increasing the project's overall cost. Data collection can be done in various ways, and WMG at the University of Warwick wanted to offer an innovative multi-sensor wireless data acquisition tool that can be deployed across industries to improve manufacturing accuracy and efficiency.

Solution

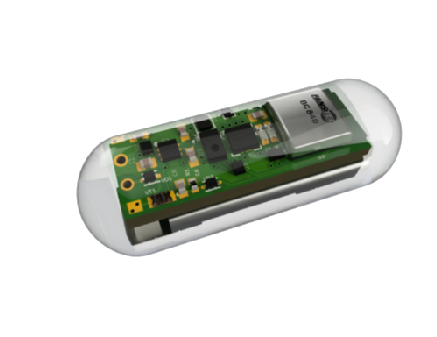

The researcher, Dr Dmitry Isakov, an Assistant Professor at WMG and his team developed and tested the device (called Smart Stirrer) that comprises a multi-functional sensor system, midrange Bluetooth module and System on Chip (SoC) and protecting housing manufactured in the form of a conventional magnetic stirrer bar. The team recognised that magnetic stirrers could be the best vehicle for a sensor that captures multiple parameters. Through a series of experiments, it has been demonstrated the performance of the Smart Stirrer capable of accurate in-situ monitoring of the physical properties of the chemical reaction, such as temperature, conductivity, visible-light spectrum, opaqueness, and viscosity. A prototype with components cost < £35 has demonstrated excellent work in laboratory conditions when conducting titration and oscillation reactions.

The functionality of the Smart Stirrer is implemented using open-source code in accordance with the user's needs. The team is currently working on the implementation of the Smart Stirrer into the IoT platform thus enabling even further to extend the application of the device.

Impact

Using an array of sensors combined with a low-cost wireless transmitter, all in a small chemically resistant package creates a powerful measuring device placed in-situ into the reactor and operating in conjunction with data storage on the cloud. The data processing by machine learning algorithms will facilitate the task of reproducibility of results and reduce the influence of the human factor. The feedback system will simplify this task using software algorithms and robotizing the production process.

Dmitry Isakov, WMG, commented, “The beauty of the Smart Stirrer is that it can be used everywhere, such as a sealed vessels thus minimising the contamination of the reactor. It may give a push to new discoveries as well. It is easy to integrate the stirrer into the labware family and make it “speak” to other lab equipment.”

Samuel Baldwin, from the Mathematics institute at the University of Warwick worked on the smart stirrer during his WMG summer internship, he added: “We have leveraged state-of-the-art technology to build a device with very low power consumption, a broad range of sensor capabilities, and high data-throughput over the Bluetooth Low Energy platform.

The laboratory of the future is that of automation, reproducibility, and safety; our all-in-one Smart Stirrer device eliminates the need for a vast array of individual wired sensors whilst maintaining the control and customisability that one would expect from any piece of advanced laboratory equipment. I look forward to seeing the Smart Stirrer solve laboratory problems and help us understand complex reactions.”

The Smart Stirrer can be an essential element in the future digital laboratory platform – a concept currently developed by the team. Digital laboratory would allow interaction with laboratory equipment (hot plates, switches, pumps) using single-board computers making such equipment “smart” by replacing the manual control with electronic (while using the same manual equipment). Such a platform will provide an unprecedented level of detail and enable monitoring of experimental tasks remotely, thus contributing to the continuation of progress in innovation and research.

The future of this project is to gain further insights into how this product can benefit end-users. The product is currently available for lease and will be available for purchase in the future. The team are keen to learn to more about improving the product for machine learning and to create the most useful device. For more information, email wmgbusiness@warwick.ac.uk.

Nikolay Cherkasov*, Samuel Baldwin, Gregory J. Gibbons, and Dmitry Isakov*