Success Story

WMG helps R53 Engineering Ltd to save time and materials while improving product performance with metal additive manufacturing

R53 Engineering Ltd (R53) is a UK based small to medium enterprise that provides quality and effective solutions to high performance engineering industries including, motorsport, defence and automotive. Its division, ‘R53 Suspension’ develops suspension systems for high performance applications using the latest technologies.

The Challenge

Suspension components are highly complex; consisting of multiple parts to achieve their required functionality, making manufacturing expensive, challenging, and often time consuming. R53 traditionally manufactures these parts through machining of wrought 7075-T6 aluminium alloys but innovation was being restricted by their existing manufacturing capabilities.

The initial challenge was to identify alternative alloys that would offer equivalent or superior mechanical performance by introducing the process of metal Additive Manufacturing (AM), widely known as metal 3D printing, a technology that R53 was hopeful would enable the development of lighter and more efficient dampers.

The second challenge was to redesign their dampers against demanding specifications including, the reduction of multiple-part assemblies to single components, optimising internal fluid flow paths and enabling weight reduction and improved efficiency and performance, whilst ensuring manufacturability of the designs using metal AM.

To help achieve their goals, R53 partnered with WMG and Canada-based, Precision ADM Inc. (PADM), and received funding from Innovate UK through the ‘UK and Canada: Enhancing Industrial Productivity’ program.

Solution

The team at WMG worked together with PADM and R53 to create a new damper design based on key specifications and a Design for AM (DfAM). Taking advantage of the design flexibility offered by AM, the team were able to create lightweight and functionally optimised dampers that enhanced build speed, reliability and quality, whilst reducing costs.

The design optimisation process conducted by PADM focused on streamlining the flow paths and linking them to the interface boundary conditions, so material was built up only where necessary. This led to a design with the lightest weight geometry. Part consolidation methodologies were also employed to integrate parts to reduce weight and production time, and to reduce maintenance costs. PADM also deployed AM process simulation tools to predict part distortion and to guide the redesign and AM build set-up, to achieve optimal part accuracy.

Materials were identified by WMG through a detailed review of literature and the AM sector, using a ‘decision-matrix’ method to list and rank potential materials.

WMG went on to develop the processing window for Laser Powder Bed Fusion (L-PBF) metal AM based on R53’s component requirements through an extensive systematic experimental study. The parameters were refined to reflect changes in wall-thickness and surface build angles, optimising for material density, mechanical properties, and surface finish. Heat treatments were identified to obtain optimum microstructure and minimum defects. Through these processes, mechanical properties superior to the 7075-T6 alloy were achieved.

Full-scale components were manufactured by PADM and validated for operational efficiency by R53. These were supplied after each major redesign, with substantial weight savings and efficiency improvements demonstrated at each stage.

Impact

-

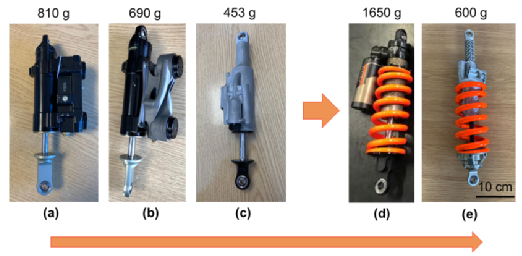

At project end, the damper offered a 44% weight reduction over the traditionally manufactured damper: Fig. 1 (a) to (c).

-

A further 64% weight reduction (600g) was achieved by implementing lattice structures compared to conventionally manufactured (multi-component) assemblies: Fig. 1(d) to (e).

-

A 10% faster reaction time was achieved due to the optimised fluid flow paths.

Roger Estrada, R53 Managing Director commented: “The aluminium metal 3D printing not only achieved weight reduction by creating an aesthetically pleasing design, but it also gave us several benefits including improved overall performance of the components, quick prototyping, shorter time to market, with significantly reduced costs from machining to overall cost. Above all, it allowed us to design a part that has better mechanical properties than its counterpart”.

Fig. 1 Damper comparison (a) conventionally manufactured assembly (multi-component)- 810 g; (b) combination of conventional and AM component assembly – 690 g, (c) integrated AM assembly (combining multiple components) - 453 g (44% less than conventionally manufactured, a). Further weight reduction achieved through lattice structure: (d) conventionally manufactured assembly (multi-component)- 1650 g and (e) fully assembled with lattice structure – 600 g (64% less than conventionally manufactured, d).

Written by:

Dr Hiren R. Kotadia, Senior Lecturer, School of Engineering, Liverpool John Moores University, and Professor Gregory Gibbons, Head of Additive Manufacturing, WMG, University of Warwick