Success Story

Waste heat recovery project boosts NET Zero credentials for Kingfisher Enamelling

WMG works with Midlands manufacturer Kingfisher Enamelling to reduce its energy consumption, remove reliance on natural gas within the factory, and meet its Net Zero targets within scope 1 emissions.

Company Background

West Midlands based Kingfisher Enamelling specialises in the vitreous enamelling of cast iron and steel components. The core of their business lies in enamelling Rayburn cookers but extends to other products such as woodburning stoves, bathroom products, and even vintage automobile restoration.

The Challenge

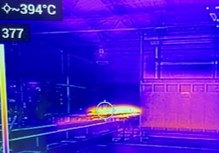

On a mission to reduce costs and emissions in the business, Kingfisher approached WMG with the aim to determine if wasted heat could be recovered from their furnace used in the enamelling process for reuse in various other parts of the business. They had noticed that when the doors of the furnace were opened, heat escaping was burning the roof panels above. This really got them thinking about the potential of it being channelled elsewhere, with more productive results!

The Solution

Sustainable manufacturing innovation manager Laura DowneyLink opens in a new window and WMG engineer Jack DaviesLink opens in a new window undertook a feasibility study using simulation techniques to model the current and future state of the furnace room with a view to creating a business case for recovering waste heat from the furnace to be redirected to the drying rooms.

Step 1 Gather Data

Laura and Jack made a site visit to start collecting the vital data that would create meaningful and robust simulations. Ultimately, they needed to see if there was enough available thermal energy from the furnace waste to heat the drying rooms rather than using the current gas heaters. They measured room dimensions and monitored room temperatures to calculate how much thermal energy was needed in the drying rooms. The also investigated if the heat could be released and rediverted again.

Step 2 Work out how the heat can be diverted

The team then went on to examine how the heat could be diverted from cooling parts and the furnace door using a combination of hoods and fans to the drying rooms. Once initial simulations were completed another phase of thermal simulations was carried out looking at different venting and insulation options for the drying room as well as material choices and dimensions of equipment for a hood and extraction system in the furnace to capture the heat.

Step 3 Measure the Impact

Through the simulations a business case was made to validate that the furnace waste heat could be used to heat the three drying rooms on the shop floor and a system design was created that would keep the drying room at the optimum 35°C.

It was established that once implemented, Kingfisher could save:

- 23,000-115,000 kWh in energy usage

- Up to £11.5 k in energy costs

- 4,600-23,000 kgCO2 per year (which equates to driving at least once around the world in a petrol car)

Most importantly, the project helped to reduce energy consumption and remove reliance on natural gas within the factory.

“WMG staff provide a range of knowledge and expertise which we just did not have. Added to this, their drive and commitment to help SMEs is immeasurable.”

Leslie Sharp, Director, Kingfisher Enamelling

“This project is a blueprint for how manufacturers can take wasted heat and reuse it in other areas of the business. It has been a delight to support Kingfisher Enamelling with this project. We offer practical support to get SME manufacturers up and running on their journey to Net Zero.”

Laura Downey, Sustainable Manufacturing Innovation Manager, WMG

For more information on working with WMG, please email wmgsme at warwick dot ac dot uk