Success Story

Patternmaking specialist Alphateq transforms digitally through WMG internship programme.

Securing a job at the end of his WMG internship, Shantnu Mehta successfully embedded an ERP and digital costing system that will dramatically improve the client conversion process at Alphateq and boost turnover by £250,000.

Background

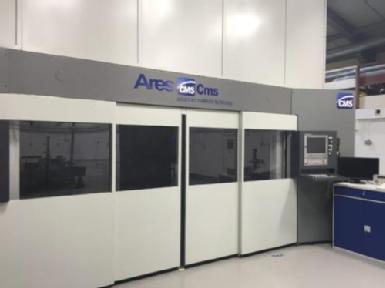

Warwickshire based AlphateqLink opens in a new window are a leading designer and manufacturer of fixtures and tooling for the foundry and specialist automotive and aerospace industries. They have a highly experienced senior team of expert pattern and toolmakers, and in-house CAD designers, using a wide range of sophisticated state-of-the-art 5 axis CNC machines.

Challenge – Making digital work in a traditional business

Whilst Alphateq has a long heritage in patternmaking, managing director Brian GarforthLink opens in a new window recognised that digital technology was going to play an ever more meaningful role in the future development of the company. Due to their clients’ demand for more sophisticated quoting methodologies, Alphateq were looking for a new system that would better capture job times and material cost data to enable a better understanding of their individual project breakeven and profitability levels, ultimately to improve their competitive positioning.

Their job flow process was largely paper based which resulted in a great deal of time being dedicated to project management to stop the accumulation of jobs at one station. By implementing digital manufacturing techniques there was scope to develop a more efficient process, to free up management time for higher value-added activities and to identify where true costs were being absorbed.

Solution – Reach out and look for new skills.

Alphateq were advised to install an ERP system as a solution to their digital transformation and process optimisation. However, they needed an internal champion to implement the system and via their independent marketing advisor Carl Jarvis, they discovered the WMG Interns for Manufacturing Businesses scheme. Through the scheme they appointed Shantnu Mehta, an Engineering Business Management graduate from the University of Warwick who had experience in systems integration. Shantnu was supervised by WMG engineer Manikanta RaviLink opens in a new window who provided additional guidance and technical support.

Reinforced by a carefully crafted programme of training, with some reconfiguration and a series of trials and pilots, Shantnu successfully implemented the ERP system as the main SFDC (Shop Floor Data Capture) system to keep track of all the jobs. He trained each Alphateq team member on the system, including how to input data on tablets, and delivered a series of briefings to the management team. The ERP’s digital Kanban board was established to visualise, in real-time, all the jobs and the respective stations and operators assigned to each job. This helps the managers track the jobs on the shopfloor and allows the assignment of new jobs to the operator, machine, and station. Once all the jobs are finished, the analytics for time and cost taken to produce them is created which displays the profit or loss made on that job, providing valuable data to feed into the quotation process.

Impact – Increased control, profitability, and new role created.

- As a result of the new system everyone in the company has enjoyed more transparency on what is happening out on the shop floor, which should boost productivity by 15%

- Shantnu has been offered a permanent position at Alphateq as a Manufacturing Systems Engineer to manage that valuable data flow through production, planning, budgeting, and resource allocation into the marketing and business development process.

- With better costing data now, Alphateq aims to increase their client conversation rate by 10% this year which could result in additional turnover of £250,000

- The reduction of paper at the business has boosted their green credentials and the ERP system will provide them with the opportunity to better optimise machine usage, leading to reduced energy costs

“The successful delivery of this project by Shantnu provides an important step change for Alphateq on their digital growth journey. Importantly by recruiting Shantnu they can continue to make changes and transform further.”

Manikanta Ravi, WMG, University of Warwick

“Working with WMG’s Intern programme has been such a fruitful process, we couldn’t have asked for anymore. Their support in posting the job ad, coupled with their handling of the candidate shortlist and shared interview process made the whole journey run nice and smoothly. Having finally settled on Shantnu, as our ideal intern, we were delighted with the whole outcome. At the end of his 3-month Internship and having added such a great deal of value to this project, and our business, we had no hesitation in offering Shantnu a full-time position with us.”

Brian Garforth, Managing Director, Alphateq Ltd

“This internship helped me understand the practical side of manufacturing business and processes. I had experience of working with digital transformation technologies in the automotive industry but from this internship, I now have experience of digital transformation in a manufacturing environment as well.”

Shantnu Mehta, Intern, WMG