WMG News

Professor of Data Science awarded a Turing AI Acceleration Fellowship

Giovanni Montana, Professor of Data Science at WMG, has been awarded a Turing AI Acceleration Fellowship.

Professor Giovanni Montana’s project, Multi-Agent Deep Reinforcement Learning for Sequential Decision Making in Real-World Applications, aims to make advances in Deep Reinforcement Learning (DRL), an area of machine learning which teaches artificial decision makers such as robots and software agents how to interact with the world in order to achieve a desired goal. By allowing autonomous systems to learn a wide range of skills without human intervention, DRL will allow them to be effective in various applications, such as industrial assembly lines and warehouse management systems, driverless cars and in decision making for the most appropriate form of medical treatment for patients.

Giovanni comments “I am thrilled to have been awarded such a prestigious fellowship that will support an exciting research programme in AI over the next 5 years. The project will aim at developing systems of artificial decision-makers that interact with the real world and autonomously develop collaborative strategies. For instance, in advanced manufacturing, we’ll develop self-coordinating robots in assembly lines that can carry out many different tasks and adapt to changing environments. In digital healthcare, we’ll leverage large volumes of historical NHS data to create an artificial team of specialised clinical experts that can reason under uncertainty and make joint decisions about patient care.”

Science Minister, Amanda Solloway said: “The UK is the birthplace of artificial intelligence and we have a duty to arm the next generation of Alan Turings with the tools that will keep the UK at the forefront of this remarkable technological innovation. The inspirational fellows we are backing today will use AI to tackle some of our greatest challenges head on, transforming how people live, work and communicate, cementing the UK’s status as a world leader in AI and data.”

Digital Minister, Caroline Dineange, said: "The UK is a nation of innovators and this government investment will help our talented academics use cutting-edge technology to improve people's daily lives - from delivering better disease diagnosis to managing our energy needs."

EPSRC Executive Chair Professor Dame Lynn Gladden said: “The Turing AI Acceleration Fellowships will support some of our leading researchers to progress their careers and develop ground-breaking AI technologies with societal impact. By enhancing collaboration between academia and industry and accelerating these transformative technologies these Fellowships will help to maintain and build on the UK’s position as a world leader in AI.”

Early construction of prototype innovative light rail vehicle for the City of Coventry

The Coventry Very Light Rail (VLR) is an innovative light rail system which will be battery powered, lightweight and rail-based.

In March 2019 a 3D simulation of the vehicle was released, and even with Covid-19 lockdowns, the vehicle build is progressing on schedule at NP Aerospace in Coventry.

On the 25th November Coventry City Councillor Jim O'Boyle, Coventry Cabinet Member for Jobs and Regeneration, took the opportunity to see how the construction of the prototype, developed by engineers at WMG, University of Warwick for the City of Coventry is progressing.

On the 25th November Coventry City Councillor Jim O'Boyle, Coventry Cabinet Member for Jobs and Regeneration, took the opportunity to see how the construction of the prototype, developed by engineers at WMG, University of Warwick for the City of Coventry is progressing.

WMG, University of Warwick have been working with TDI (Transport Design International) to deliver the novel very light rail vehicle, which as demonstrated in the photos is swiftly reaching completion with the driver’s desk and other sub systems now in place. The vehicle is expected to be finished in February 2021 ready for testing at the new rail innovation centre in Dudley.

Dr James Meredith, from WMG at the University of Warwick comments:

“WMG are delighted that the vehicle build is running on plan in spite of Covid-19. The project is an excellent showcase for UK engineering and manufacturing with over 70 % UK content. We look forward to testing the vehicle in 2021 alongside the innovative low cost trackform we are developing in parallel.”

Cllr Jim O’Boyle, Coventry Cabinet Member for Jobs and Regeneration, said:

Cllr Jim O’Boyle, Coventry Cabinet Member for Jobs and Regeneration, said:

“It is very exciting to see the VLR prototype take shape and for the project to take another big step towards becoming a reality.

“VLR will make a massive difference to our city, revolutionising travel and helping the environment. It will help keep our city at the forefront of the new transport industry and help us to attract new firms and jobs to take the city forward. It also helps cement our position at the centre of the green revolution with work such as UK Battery Innovation Centre.

“There has been some amazing work by all the project partners in some very difficult times and I can’t wait to see the next stages and watch it come out of the design rooms and on to our city’s streets.”

Darren Smith, Head of TDI comments:

“TDI are extremely pleased with the progress to date on the project and are looking forward to delivering the vehicle to our client in early 2021, so that it can begin its testing phase at the new VLRIC in Dudley. The teams involved in the delivery process across our full supply chain have worked tremendously hard, under difficult circumstances this year and I would like to thank them all for their efforts.”

James Kempston, CEO NP Aerospace, comments:

“It’s great to see the progress that has been made on the Very Light Rail project at our facility in Coventry at a time when all businesses are feeling the pressure of the pandemic. The platform will offer significant benefits for local people and the wider economy and we are honoured to have been selected to be part of the project. The team have worked very hard to ensure a high level of build quality and we are looking forward to the final release of the vehicle early next year. It is also very encouraging to be part of a development which will have a significant environmental impact.”

ENDS

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Woven Light Rail Design wins Gold at JEC World 2020 Innovation Awards

The BRAINSTORM project, which saw partners from Far-UK, Composite Braiding, TDI and WMG at the University of Warwick create a woven braided  carbon fibre composite frame for a Very-Light Rail (VLR), has won gold at the JEC World 2020 Innovation awards in the Category “Railway Vehicles and Infrastructure.”

carbon fibre composite frame for a Very-Light Rail (VLR), has won gold at the JEC World 2020 Innovation awards in the Category “Railway Vehicles and Infrastructure.”

The JEC World 2020 Innovation awards is the world’s leading international composites show, the awards ceremony took place virtually, and saw researchers working on the BRAINSTORM project take home gold in the category “Railway Vehicles and Infrastructure.”

The Innovate UK funded project started in 2018, and engineers from Far-UK, TDI, Composite Braiding and WMG, at the University of Warwick set out to make a lightweight VLR vehicle frame, which is braided from carbon fibre composites into a series of tubes. They created their first prototype demonstrator frame in May 2019, which drew attention from the then Parliamentary Under Secretary of State and Minister for Business and Industry, Andrew Stephenson.

The frame is unique as it can be easily assembled by adhesive and simple welding, and can be repaired if damaged, and recycled or reused in other structures at its end of life.

Dr Darren Hughes Associate Professor in Materials and Manufacturing at WMG at the University of Warwick explains:

“It is an honour to have won at the JEC World 2020 Innovation awards, we have worked incredibly hard to create an innovative frame offering significant weight-saving that can allow VLR light rail services to operate in a more sustainable way. Reduced mass leads to a lower requirement for power for propulsion and also lowers the stress placed on the track system. This can also open up significant cost savings in light rail systems.”

“The technology also ensures that the vehicle is tough for a long life in service, easily repairable and strong enough to protect the passengers on board.”

Dr Kevin Lindsey of Nottingham based lightweight structural composite components company Far-UK Ltd said:

“To have our achievements acknowledged and awarded is validation of our ongoing research into lightweight structures. The design process that we used allowed the development of the ultralight yet safe structure. We are now ready to take structures such as these into higher volume in our new manufacturing facility.”

Steve Barbour of Derby based specialists in thermoplastic braiding company Composite Braiding Ltd said:

“It is great that the technology we have been developing has helped lead to such a fantastic outcome. Braiding at rates of over a mile a day, we have a highly automated process that is capable of producing high volume, lower cost structural components that are inherently recyclable. It’s fantastic that the potential has been recognised.”

Paul Salkeld of TDI (Transport Design International) based at Stratford-Upon-Avon adds:

“The braiding method can be used with a wide range of materials including carbon, glass, basalt and aramid. We hope this can revolutionise the design of future transport, and are actively involved particularly in the rail sector to produce more economical and environmentally beneficial vehicles.”

Innovative partner awarded contract to develop very light rail trackform

The Coventry Very Light Rail project is about to embark on a new adventure, investigating how to create a low cost trackform for the light rail carriages already in development, thanks to £1.5m funding from West Midlands Combined Authority (WMCA), secured by CCC. This project aims to revolutionise affordable public transport in towns and cities.

The Coventry Very Light Rail project is about to embark on a new adventure, investigating how to create a low cost trackform for the light rail carriages already in development, thanks to £1.5m funding from West Midlands Combined Authority (WMCA), secured by CCC. This project aims to revolutionise affordable public transport in towns and cities.

So far in the Coventry Very Light Rail project, Engineers from WMG, University of Warwick have worked with TDI to design a battery-powered light rail vehicle for Coventry City Council. The long term objective is that it will become an autonomous vehicle that can hold 50 passengers and work like the London Underground system, where there is no timetable and people can hop on and off.

The vehicle will be lightweight in design using a multi-material approach. Due to being battery-powered there will be no overhead power supply, which is both costly and unsightly.

However researchers are now about to embark on their next venture of the VLR project, as they have received £1.5m via CCC to develop a low cost trackform for light rail. Engineers at WMG will work with Coventry City Council and a major French civil engineering company - Ingerop Conseil et Ingénierie.

The ultimate goal of the track project is to design an affordable trackform that can be easily removed and will reduce impact on utilities, saving hundreds of thousands of pounds digging up roads and moving gas, electric, telecommunication and sewage systems, which is currently the process for building traditional tram systems.

Dr Darren Hughes, Associate Professor at WMG, University of Warwick comments:

“The Coventry light-rail project brings together advanced technologies from a number of sectors to deliver a low-cost environmentally-sustainable public transport solution.

“Now that the vehicles have been designed it is time to look at the track they will run on, and with the help of Ingérop Conseil et Ingénierie, we will make it as affordable and environmentally friendly as possible.”

Councillor Jim O’Boyle, cabinet member for jobs and regeneration said:

“Our plan for Very Light Rail has the potential to transform the way people travel. It will be delivered at a much lower cost than traditional trams, a hop on, hop off service part of the green revolution and of course its innovation born in Coventry.

“While the development of the vehicle is progressing well, we also need to innovate in the development of the track and that’s exactly what Ingérop will be able to help with. Experts in this field we will be setting them the challenge of designing track that that can be laid much more quickly and therefore much more cheaply than traditional track.

“Very Light Rail is a really exciting project. Another innovative first for Coventry and this is another important step in its delivery.”

Philippe-André Hanna, Director for International Transport in Ingérop said:

“We are delighted to join the team for the Coventry Very Light Rail. This project is an absolute need for small and medium cities who want to have a modern, carbon-free, rail-based system and cannot afford it today. After the R&D phase, our real goal as on all our projects around the World is to put in place the most sustainable urban transport system for Coventry and many more cities in Europe."

Tim Hackett, Infrastructure Director at Rendel Ltd said:

“We are really excited to be part of this project with our colleagues from Ingérop having already worked together successfully on some high-profile and complex rail projects. We look forward to collaborating on this innovative and technologically game-changing project, providing support from our new West Midlands office.”

WMG staff use 3D printing in the fight against COVID-19

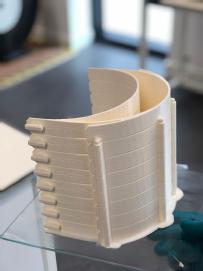

A team of WMG academics, technicians and engineers are using their 3D Printing skills, to help in the fight against COVID-19, by producing face shields for NHS front-line staff.

A team of WMG academics, technicians and engineers are using their 3D Printing skills, to help in the fight against COVID-19, by producing face shields for NHS front-line staff.

As the supply of PPE became a key issue in the pandemic, technicians Phil Gibbons, Joseph Benjamin and Martin Worrall, and PhD student Kevin Couling responded to 3D Crowd’s call asking volunteers to use their 3D Printing capabilities to produce face shields.

WMG’s nine 3D printers have now been programmed to run around the clock producing more than 400 shields each week.

The first batch of face shields have now been vigorously inspected, cleaned, packaged and distributed to 3D Crowd’s central assembly station in Warwickshire. They will now be sent to organisations running low on supplies.

The team have also managed to order extra materials and will keep the printers running until supplies literally run out.

Reader Greg Gibbons explains: “Demand for PPE is incredibly high, and we are in a unique position to be able to help.

“We have 3D Printers running in our Degree Apprenticeship Centre (DAC) and we are also planning to open up our Materials Engineering Centre (MEC) to enable mass production of the shields.”

In addition to the work with 3D Crowd, and with funding from WMG Centre High Value Manufacturing Catapult, the team are also working in collaboration with Queen Mary University of London on the development of an injection moulding process for face shield to enable mass production of the frame.

Associate Professor Jérôme Charmet, and Post-Doctoral Research Associate Rui Rodrigues explain: “It is fantastic that we are able to respond to this call and work towards providing the protection to the NHS that is so desperately needed.

“We are now finalising a tool design before we begin production. Once the process is up and running we then plan to transfer manufacture to Andel Plastics, an Injection Mould SME, who will continue with large scale production.”

Car batteries can be frozen for safer transportation

Currently transporting damaged and defective car batteries is an expensive process as they need to be placed in an explosion proof box which costs thousands of pounds, however researchers from WMG at the University of Warwick in collaboration with Jaguar Land Rover engineers have been able to freeze batteries with Liquid Nitrogen.

An explosion proof box to transport a typical Tesla sized battery costs €10,000 and a further €10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

€10,000 for the UN accreditation, however, the ability to transport them in plastic containers which cost a couple of hundred pounds has been made more accessible thanks to researchers from WMG at the University of Warwick.

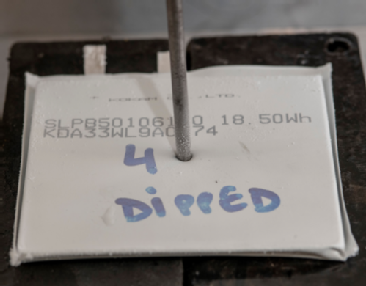

In the paper, ‘Cycle life of lithium ion batteries after flash cryogenic freezing’ published in the Journal of Energy Storage, researchers highlight that cryogenic freezing does not reduce lithium ion battery’s energy capacity or affect cycle or service life, and could be transported in a safer way.

As the sales of electric vehicles increases, there is more concern for the transportation of damaged and defective lithium ion battery packs. Currently, it is an expensive process, as they are put in an explosion proof box that costs €10,000 and a further €10,000 for the UN accreditation, which EV manufacturers are picking up the bill for.

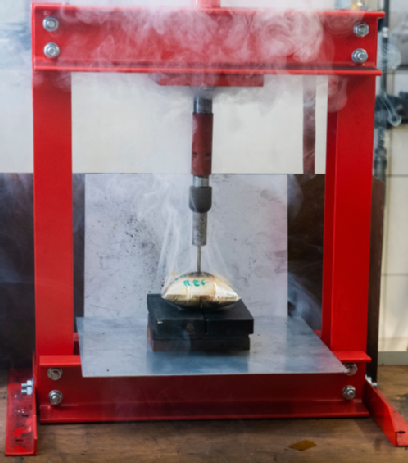

Explosion boxes are used to contain the battery in case it goes into thermal runway, an overheating condition which can lead to violent explosions and toxic gases being released. However being able to cryogenically flash freeze the batteries completely removes the risk of an explosion, and could therefore mean they can be transported safely in a plastic box.

Researchers who were part of the ELEVATE project funded by EPSRC, WMG Centre High Value Manufacturing Catapult, and  supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

supported by Jaguar Land Rover tested the batteries activity before they froze cells with liquid nitrogen and after, they also drove nails through the frozen cell to test the safety of them, and managed to show that their performance was not effected after freezing.

When being transported batteries will have to be kept in a lorry at -35 degrees, however the amount of packaging is significantly less than explosion proof boxes, making the process more sustainable.

Dr Thomas Grandjean from WMG, at the University of Warwick comments:

“Transporting damaged and defective batteries is an expensive and unsustainable process, however being able to freeze them with liquid nitrogen could save thousands of pounds and help electric vehicle manufacturers be more sustainable.

“We tested the batteries in the most extreme abuse conditions, such as driving nails through the cells and inducing external short circuits, proving that the freezing process is effective and safe.”

ENDS

2 DECEMBER 2019

NOTES TO EDITORS

High-res images available credit to WMG University of Warwick at:

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_3_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_5_.png

Caption: A frozen battery cell with a nail through it

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_7_.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_6.png

Caption: A room temperature cell with a nail through it exploding

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/batts_2_.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

https://warwick.ac.uk/services/communications/medialibrary/images/december2019/untitled.png

Dr Thomas Grandjean from WMG, University of Warwick handling the battery cell frozen by liquid nitrogen

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or + 44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Department for Transport to give keynote address at WMG’s Very Light Rail Conference

On the 28th November 2019, Steve Berry OBE, Head of Highways Maintenance, Innovation, Resilience, Light Rail and Cableways at the UK Department of Transport will give the keynote address at the Very Light Rail Conference being held at The Slate on the University of Warwick’s campus. He will speak about the potential for Very Light Rail to transform local public transport.

Steve Berry will be joined by industry speakers and academics involved in developing very light rail, including local companies TDI and RDM. They will talk about three projects that are underway across the West Midlands, and discuss why the West Midlands is leading the way in VLR.

As the UK population continues to grow along with traffic congestion and vehicle emissions, new transport options are needed to create modal shift and encourage people to leave their cars at home.

At present buses and trams (light rail) provide alternatives to private cars, but bus patronage has been falling steadily for many years in contrast to tram ridership which has taken passengers out of their cars. However, tram routes are expensive to construct and can only be afforded by large city conurbations such as Birmingham. That said, Very Light Rail (VLR) may be a solution that medium sized cities could afford.

Very Light Rail is a lower cost, zero emission option for sustainable transport. The technology can be applied to branch lines as well as urban rail (trams). The Coventry VLR scheme aims to reduce the cost through the delivery of lightweight, battery electric vehicles combined with a novel track form, the first system of its kind in the world.

3D visualisations of the Coventry VLR vehicle were unveiled earlier this year. The lightweight vehicle is fabricated from a combination of steel, aluminium and composite components and will be capable of carrying 50 passengers.

3D visualisations of the Coventry VLR vehicle were unveiled earlier this year. The lightweight vehicle is fabricated from a combination of steel, aluminium and composite components and will be capable of carrying 50 passengers.

Unlike traditional trams, the Coventry VLR system will not have overhead cables – the vehicle will be powered by an on-board battery which will be rapidly charged at the end of the route. The vehicles will run on a novel prefabricated track form which be easy to install into the road and remove, negating the need to utility companies to relocate their equipment (which is a significant cost in light rail tram solutions).

Currently the system is being designed to meet Coventry City’s needs, but it is expected other medium sized cities across the UK, such as Leicester and Derby, may follow in due course.

Dr Nick Mallinson from WMG, University of Warwick comments:

“At WMG we’ve been working on very light rail technology with a number of industry partners for 5 years. Progress achieved to date recently convinced the Department for Transport that the time is right for a conference to showcase the work and make local authorities, transport planners and industry aware of the potential for very light rail solutions”

To see the full agenda and register your interest in the event please fill out the form at: https://warwick.ac.uk/fac/sci/wmg/mediacentre/wmgevents/vlr/

ENDS

22 NOVEMBER 2019

NOTES TO EDITORS

High-res images available at:

Please credit the following images and videos to: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/november2019/9.jpeg

https://warwick.ac.uk/services/communications/medialibrary/images/november2019/3.jpeg

https://warwick.ac.uk/services/communications/medialibrary/images/november2019/6.jpeg

https://warwick.ac.uk/services/communications/medialibrary/images/november2019/7.jpeg

https://warwick.ac.uk/services/communications/medialibrary/images/november2019/8.jpeg

https://warwick.ac.uk/services/communications/medialibrary/images/november2019/11.jpeg

https://warwick.ac.uk/services/communications/medialibrary/images/november2019/1.jpeg

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Bionic hand made in 10 hours thanks to WMG, University of Warwick

A bionic hand can be made to measure in 10 hours and can grip using a moveable thumb. Designers and engineers from WMG, University of Warwick and UK industry, have been able to entirely 3D Print the device with embedded electrical circuitry to seamlessly connect sensors and actuators.

The IMPACT project, led by Iterate Design and Innovation Ltd, in collaboration with WMG, University of Warwick, C Enterprise (UK) Ltd and Printed Electronics Ltd, was made possible thanks to a grant of nearly £900,000 from Innovate UK, with the aim of developing a 3D printing technology with the ability to print plastic products with integrated electrical circuitry, a capability which they have demonstrated in a bionic hand.

The IMPACT project, led by Iterate Design and Innovation Ltd, in collaboration with WMG, University of Warwick, C Enterprise (UK) Ltd and Printed Electronics Ltd, was made possible thanks to a grant of nearly £900,000 from Innovate UK, with the aim of developing a 3D printing technology with the ability to print plastic products with integrated electrical circuitry, a capability which they have demonstrated in a bionic hand.

The IMPACT hand has taken inspiration from a similar developed by Ambionic’s Ben Ryan, whose son had his forearm amputated after birth, and who decided to make him a new one.

The IMPACT team have taken this design further by embedding the electrical circuitry linking the motion controlling muscle sensors with the motors and battery into the structure of the bionic hand, thus providing a durable and aesthetic solution.

Engineers at WMG, University of Warwick have tested the durability of the printed electrical circuitry to understand how well they will endure the bending and flexing that they might experience in use.

They also developed a website so that people can interact with the manufacturers to order a 3D Printed hand, allowing them to insert the measurements of their arm, and select what colour they want their hand to be, providing them with a tailored and personalised product.

10 hours later the hand will be printed with the sensors inbuilt ready for use.

Within the project, Iterate Design and Innovation Ltd developed the design of the hand, including the integration of the electrical circuitry and sensors. Printed  Electronics Ltd developed the technology for printing the electrical circuitry within the 3D Printing process and C Enterprise (UK) Ltd developed the multi-axis, multi-material 3D printer that enables the hand to be realised in 3D.

Electronics Ltd developed the technology for printing the electrical circuitry within the 3D Printing process and C Enterprise (UK) Ltd developed the multi-axis, multi-material 3D printer that enables the hand to be realised in 3D.

Dr Greg Gibbons of WMG University of Warwick comments:

“WMG are delighted to be a partner in the IMPACT project, helping to deliver this innovative and revolutionary technology, which is undoubtedly helping put UK PLC at the forefront of 3D Printing research and development globally.”

Gethin Roberts, Project Lead and MD of Iterate Design + Innovation comments:

“The IMPACT project has resulted in the creation of an exciting new technology that has the ability to print electro-mechanical parts and assemblies, which weren’t previously possible. Through laying down conductive ink tracks within polymer structures means that parts produced are fully functional straight off the machine bed; offering huge productivity benefits.”

ENDS

14 NOVEMBER 2019

NOTES TO EDITORS

High-res images available credit to Iterate UK/Ambionics

https://warwick.ac.uk/services/communications/medialibrary/images/november2019/arm_pic.jpg

https://warwick.ac.uk/services/communications/medialibrary/images/november2019/silver_ink_track.jpg

About WMG

WMG is a world leading research and education group transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes.

As an international role model for successful partnerships between academia and the private and public sectors, WMG develops advancements nationally and globally, in applied science, technology and engineering, to deliver real impact to economic growth, society and the environment.

WMG‘s education programmes focus on lifelong learning of the brightest talent, from the WMG Academies for Young Engineers, degree apprenticeships, undergraduate and postgraduate, through to professional programmes.

An academic department of the University of Warwick, and a centre for the HVM Catapult, WMG was founded by Professor Lord Kumar Bhattacharyya in 1980 to help reinvigorate UK manufacturing and improve competitiveness through innovation and skills development.

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Ceramic industry should bring carbon reducing cold sintering process out of labs and into manufacturing says new research

A new techno-economic analysis, by a team led by a researcher from WMG at the University of Warwick, shows that the energy intensive ceramic industry would gain both financial and environmental benefits if it moved to free the cold sintering process from languishing in labs to actual use in manufacturing everything from high tech to domestic ceramics.

The new research has just been published in the Journal of the European Ceramic Society in a paper entitled “Decarbonising ceramic manufacturing: A techno-economic analysis of energy efficient sintering technologies in the functional materials sector”.

The cold sintering process (CSP) combines heat, pressure and the use of water to significantly reduce energy use as it lowers the temperatures required to produce ceramics to around 300 degrees centigrade. This is far less than other process such as: Conventional sintering, Laser sintering, Fast-firing sintering, Liquid-phase sintering, and Flash sintering which require far more energy and need to reach temperatures ranging from 1400 to 3000 degrees centigrade depending on the process and materials under consideration.

However the small scale of laboratory-based CSP (typically creating 5 grams of ceramic at a time under lab conditions) has meant that manufacturers have chosen to continue to rely on other significantly higher temperature methods that can either already produce larger amounts or can rapidly manufacture a series of small scale high tech ceramics. The University of Warwick led team believed that manufacturers had not developed anything like a full understanding of the potential financial and environmental benefits of using CSP in manufacturing – particularly as the start-up costs of CSP are much lower than other processes.

However the small scale of laboratory-based CSP (typically creating 5 grams of ceramic at a time under lab conditions) has meant that manufacturers have chosen to continue to rely on other significantly higher temperature methods that can either already produce larger amounts or can rapidly manufacture a series of small scale high tech ceramics. The University of Warwick led team believed that manufacturers had not developed anything like a full understanding of the potential financial and environmental benefits of using CSP in manufacturing – particularly as the start-up costs of CSP are much lower than other processes.

The researchers looked at scenarios for the processing of 3 separate functional oxides used to produce ceramics: ZnO, PZT and BaTiO3. They compared cold sintering (CSP) with a range of other sintering techniques and looked at its return on investment. They found that in all three cases, even after 15 years of use, the low set up costs of CSP made it the most economically attractive sintering option, with lower capital costs and best return on investment as well as considerable energy and emission savings.

The researchers do recognise that the transition from laboratory to industry of CSP will require hugely different facilities and instrumentation as well as relevant property/performance validation to realise its full potential but the potential benefits of doing so are significant .

Lead researcher on the paper Dr Taofeeq Ibn-Mohammed from WMG at the University of Warwick said:

Lead researcher on the paper Dr Taofeeq Ibn-Mohammed from WMG at the University of Warwick said:

“The rising cost of energy and concerns about the environmental impact of manufacturing processes have necessitated the need for more efficient and sustainable manufacturing. The ceramic industry is an energy intensive industrial sector and consequently the potential to improve energy efficiency is huge”

“Our research is the first comprehensive techno-economic analysis of a number of sintering techniques, comparing them with the recently developed cold sintering process (CSP). We find that there are clear financial and environmental benefits if the ceramics industry was to take the cold sintering process out of labs and into commercial manufacturing”.

Note for Editors: The full research team on the paper were: Dr Taofeeq Ibn-Mohammed from WMG at The University of Warwick; C.A. Randall and S. Berbano both from the Materials Research Institute, The Pennsylvania State University; , K.B. Mustapha from the University of Nottingham; , J. Guo from Xi’an Jiaotong University and Pennsylvania State University; J. Walker from Norwegian University of Science and Technology; S.C.L. Koh, D. Wang, D.C. Sinclair, and I.M. Reaney, all from The University of Sheffield.

Top industry award for WMG research

WMG’s BRAINSTORM research project, with Far-UK, Composite Braiding and Transport Design International (TDI), was presented with the Technical Innovation of the Year award at the prestigious Global Light Rail Awards.

WMG’s BRAINSTORM research project, with Far-UK, Composite Braiding and Transport Design International (TDI), was presented with the Technical Innovation of the Year award at the prestigious Global Light Rail Awards.

The Awards, dubbed as the industry’s Oscars, recognise outstanding achievements in the global light and urban rail sector.

Working with Far-UK, Composite Braiding and TDI, WMG researchers created a new design of an incredibly lightweight Very Light Rail (VLR) vehicle frame weaved from carbon fibre composites into a series of tubes to create a prototype demonstrator frame - the first of its kind.

Dr Darren Hughes, Associate Professor in Materials and Manufacturing explained: “Our BRAINSTORM VLR research  partnership has achieved significant weight-saving, allowing VLR services to accommodate more passengers while reducing the energy required to propel the vehicle and the stress placed on the rails and road surface.

partnership has achieved significant weight-saving, allowing VLR services to accommodate more passengers while reducing the energy required to propel the vehicle and the stress placed on the rails and road surface.

“The technology also ensures that the vehicle is tough for a long life in service, easily repairable when accidents happen and strong enough to protect the passengers on board.”

The judges praised BRAINSTORM for its innovation, vision and ambition to create not only new manufacturing processes but potentially a whole new industry.

One judge said: “This is what the industry has been waiting for decades. Aviation and automotive do this already, so it’s great to see a UK consortium bringing us up to that level. I can’t wait to see the first full vehicle next year.”

Find out more about the Global Light Rail Awards here.