WMG News

RESOLVE prototypes shape future of electric urban commuting

The future of daily urban commuting could be small, lightweight Electric L-category Vehicles (ELVs). A cost effective, energy efficient and comfortable alternative to traditional cars in cities, is at the heart of the €6.92m RESOLVE project, which included WMG at the University of Warwick.

The future of daily urban commuting could be small, lightweight Electric L-category Vehicles (ELVs). A cost effective, energy efficient and comfortable alternative to traditional cars in cities, is at the heart of the €6.92m RESOLVE project, which included WMG at the University of Warwick.

The European project – named ‘Range of Electric Solutions for L-category Vehicles’ – designed and developed two stylish tilting four-wheeler prototype ELVs with leading European manufacturers Piaggio and KTM. These demonstrators were unveiled, and presented to representatives from the European Commission, at an event in Brussels in April 2018.

WMG was one of fourteen partners in the project, which included leading names from industry and research such as Piaggio, KTM, Bosch, Ricardo, the Austrian Institute of Technology, and the University of Florence.

WMG Assistant Professors support EPSRC in ‘Manufacturing the Future’

Dr John Low and Dr Jerome Charmet have been appointed as members of EPSRC’s prestigious Early Career Forum in Manufacturing Research.

They will be tasked with establishing a community of early career academics to provide Theme Leaders at EPSRC with strategic advice to develop their themes in ‘Manufacturing the Future’. They will also act as a conduit for communication (with EPSRC), covering the broader community in manufacturing research both nationally and internationally.

Dr John Low who works in WMG’s Energy Innovation Centre, explains: “I will share my vision of manufacturing science in energy storage to help accelerate the UK’s advances in fundamental electrochemistry through to application-driven programmes.”

Dr John Low who works in WMG’s Energy Innovation Centre, explains: “I will share my vision of manufacturing science in energy storage to help accelerate the UK’s advances in fundamental electrochemistry through to application-driven programmes.”

Dr Jerome Charmet, who is based within the Institute of Digital Healthcare team said: “I will endeavour to bridge the gap between the  biomedical/clinical sciences and the manufacturing communities, in particular in the area of micro and nanotechnologies.”

biomedical/clinical sciences and the manufacturing communities, in particular in the area of micro and nanotechnologies.”

£5.6m Vehicle-2-Grid project develops charging technology in real world

Electric vehicle charging infrastructure on UK roads is to be advanced, thanks to a new £5.6 million project – funded by Innovate UK – to develop Vehicle-2-Grid (V2G) technologies, involving WMG at the University of Warwick.

For three years from April 2018, the EV-elocity consortium will conduct a project to demonstrate and develop V2G technology across a variety of UK locations, including airports and business parks – with the aim of proving its viability and worth to business and the wider public.

Researchers at WMG, led by vehicle electrification and energy storage expert Dr James Marco, will build a techno-economic model of how V2G will be viable within the UK. A key innovation will be the inclusion of new models of battery degradation within the analysis that will underpin new methods to optimise the vehicle’s battery system.

Researchers at WMG, led by vehicle electrification and energy storage expert Dr James Marco, will build a techno-economic model of how V2G will be viable within the UK. A key innovation will be the inclusion of new models of battery degradation within the analysis that will underpin new methods to optimise the vehicle’s battery system.

Dr Marco’s team will also analyse real-world usage data from a range of different electric fleet vehicles as they are used within a V2G context.

The project will break new ground in helping consumers, businesses and infrastructure providers to financially benefit from adapting their charging behaviour and vehicle use.

In doing so, the project will help to further accelerate and incentivise the transition from traditional fuel sources to electric vehicles.

New sensor tech for commercial Lithium-ion batteries finds they can be charged 5 times faster

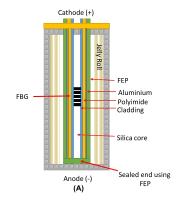

Researchers at WMG at the University of Warwick have developed a new direct, precise test of Lithium-ion batteries’ internal temperatures and their electrodes potentials and found that the batteries can be safely charged up to five times faster than the current recommended charging limits. The new technology works in-situ during a battery’s normal operation without impeding its performance and it has been tested on standard commercially available batteries. Such new technology will enable advances in battery materials science, flexible battery charging rates, thermal and electrical engineering of new battery materials/technology and it has the potential to help the design of energy storage systems for high performance applications such as motor racing and grid balancing.

Researchers at WMG at the University of Warwick have developed a new direct, precise test of Lithium-ion batteries’ internal temperatures and their electrodes potentials and found that the batteries can be safely charged up to five times faster than the current recommended charging limits. The new technology works in-situ during a battery’s normal operation without impeding its performance and it has been tested on standard commercially available batteries. Such new technology will enable advances in battery materials science, flexible battery charging rates, thermal and electrical engineering of new battery materials/technology and it has the potential to help the design of energy storage systems for high performance applications such as motor racing and grid balancing.

If a battery becomes over heated it risks severe damage particularly to its electrolyte and can even lead to dangerous situations where the electrolyte breaks down to form gases than are both flammable and cause significant pressure build up. Overcharging of the anode can lead to so much Lithium electroplating that it forms metallic dendrites and eventually pierce the separator causing an internal short circuit with the cathode and subsequent catastrophic failure.

New battery testing laboratory unveiled at WMG

Battery experts at WMG were pleased to welcome a special shipment from Austria in the shape of a new MW-scale battery research testing laboratory.

Battery experts at WMG were pleased to welcome a special shipment from Austria in the shape of a new MW-scale battery research testing laboratory.

The new high-tech laboratory, measuring 15m by 16m, was lowered into position by WMG’s Energy Innovation Centre (EIC) at the University of Warwick.

This new facility is funded through the Government’s Energy Research Accelerator (ERA) programme. There are three test modules. The first two provide battery pack testing up to a total power of 1MW, 1200V, 2400A. The third test module provides mechanical testing facilities to enable researchers to fully characterise a lithium-ion cell’s mechanical behaviour over its entire temperature and state-of-charge operating range.

Adding graphene girders to silicon electrodes could double the life of lithium batteries

New research led by WMG, at the University of Warwick has found an effective approach to replacing graphite in the anodes of lithium-ion batteries using silicon, by reinforcing the anode’s structure with graphene girders. This could more than double the life of rechargeable lithium-ion based batteries by greatly extending the operating lifetime of the electrode, and also increase the capacity delivered by those batteries.

WMG joins two new Faraday battery research projects: part of a £42 million UK initiative

Today, Tuesday January 23rd 2018, the Faraday Institution announced up to £42 million in new government funding to four UK consortia to conduct research aimed at overcoming battery challenges to accelerate the electric vehicle revolution, and WMG at the University of Warwick will be partners in two of those four new consortia.

Today, Tuesday January 23rd 2018, the Faraday Institution announced up to £42 million in new government funding to four UK consortia to conduct research aimed at overcoming battery challenges to accelerate the electric vehicle revolution, and WMG at the University of Warwick will be partners in two of those four new consortia.

The Faraday Institution, which WMG at the University of Warwick helped to form, is the UK’s independent national battery research institute, and it was established as part of the government’s £246 million investment in battery technology through the Government’s Industrial Strategy. Its formation was announced in October 2017 by the Business Secretary Greg Clark. The research it supports at organisations such as WMG at the University of Warwick aims to put the UK on the map as being at the forefront of battery technology worldwide and radically increase the speed with which we are able to make the move to electric vehicles.

Greg Clark announces £80 million funding for Coventry, Warwickshire and University of Warwick partnership to create new national battery facility

A partnership between WMG, at the University of Warwick, Coventry and Warwickshire Local Enterprise Partnership, and Coventry City Council has been awarded £80 million to establish a new National Battery Manufacturing Development Facility (NBMDF). The announcement was made by The Rt Hon Greg Clark, Secretary of State for Business, Energy and Industrial Strategy, while attending an energy conference on the University of Warwick campus on Wednesday 29th November 2017.

A partnership between WMG, at the University of Warwick, Coventry and Warwickshire Local Enterprise Partnership, and Coventry City Council has been awarded £80 million to establish a new National Battery Manufacturing Development Facility (NBMDF). The announcement was made by The Rt Hon Greg Clark, Secretary of State for Business, Energy and Industrial Strategy, while attending an energy conference on the University of Warwick campus on Wednesday 29th November 2017.

The new national facility will be established in the Coventry and Warwickshire area by WMG, the Coventry and Warwickshire LEP and Coventry City Council and it will enable UK based companies and researchers to come together to build and maintain a world leading position in manufacturing technologies for batteries and their components in vehicles and transportation. It will provide a crucial new strategic link between the research, development and full-scale industrialisation for battery technologies across the UK.

It will enable effective partnerships between manufacturers, researchers, and economic development leaders, while remaining independent from commercial interests and it will be governed with transparency.

WMG joins new £1.3 million vehicle battery recycling project

WMG, at the University of Warwick has joined a £1.3 million project with Connected Energy, Jaguar Land Rover and Videre Global to establish key components of a world leading second life battery value chain. The project is co-funded by an Innovate UK grant, awarded in October.

WMG, at the University of Warwick has joined a £1.3 million project with Connected Energy, Jaguar Land Rover and Videre Global to establish key components of a world leading second life battery value chain. The project is co-funded by an Innovate UK grant, awarded in October.

Connected Energy, a pioneer in site-integrated energy storage solutions, is based in Newcastle upon Tyne with a technical centre near Norwich. Its British designed E-STOR energy storage technology will be adapted to integrate recycled Jaguar Land Rover batteries, with other work to be undertaken by WMG on the use of varied second life battery modules. This innovative approach will further increase Connected Energy's knowledge base and performance of their E-STOR systems.

Reuse of electric vehicle batteries is compelling circular economy innovation. Second life enables greater exploitation of the carbon and energy embedded in the manufacturing of the batteries, adding to the sustainability credentials of electric vehicles as well as the electricity system. Using second life batteries also reduces system costs - making energy storage systems financially viable for a wider range of end users.

WMG at the University of Warwick is the academic research partner to the project. It is a department of the University of Warwick, and has a considerable reputation for energy storage research.

WMG software powers next generation intelligent JCBs

I ntelligent construction machines which are more fuel-efficient and environmentally friendly are set to enter the market, thanks to pioneering software developed by WMG, at the University of Warwick, and JCB.

ntelligent construction machines which are more fuel-efficient and environmentally friendly are set to enter the market, thanks to pioneering software developed by WMG, at the University of Warwick, and JCB.

The software was created as part of the Off-Highway Intelligent Power Management (OHIPM) project – a collaboration between JCB, WMG and Pektron, part-funded by Innovate UK - which sought to create the next generation of JCB vehicles.

Wanting to produce machines which emit fewer CO2 emissions, and to maintain their business performance in a changing market, JCB enlisted the world-class expertise of Dr James Marco from WMG’s energy team.

Dr Marco’s team analysed huge amounts of JCB data to establish which parts of the machine fleet could be most effectively optimised through intelligent power solutions, and how to benefit JCB’s diverse range of customers around the world.

The team at WMG then created the control software to operate intelligent engines with automotive powertrain technology, enabling them to sense when the machines are idle and make the decision to switch themselves off (or power down) when power is not required – leading to optimal energy efficiency and minimal pollution.