WMG News

Millions awarded to University of Warwick to turbocharge UK’s battery production

The University of Warwick has been awarded millions of pounds to boost British production of crucial materials for electric car batteries.

The University of Warwick has been awarded millions of pounds to boost British production of crucial materials for electric car batteries.

The £12 million in funding has been awarded by the Faraday Battery Challenge to the High Value Manufacturing Catapult at WMG at the University of Warwick, and CPI at NETPark (North East Technology Park), in County Durham.

It will be used to create the new Advanced Materials Battery Industrialisation Centre (AMBIC).

The Centre will bridge the gap between academic research and battery production and will focus on how batteries can be made to work more efficiently, as well as on equipment and skills development.

The Centre is needed to help the UK develop the electric vehicle batteries of the future, with reduced costs, more sustainable materials and improved performance.

Electric vehicle batteries make up around half the cost of a new electric vehicle, so reducing the cost of their production is crucial to lowering the cost of EVs to parity with combustion engine vehicles.

The funds are part of a wider investment strategy by the Faraday Battery Challenge and the High Value Manufacturing Catapult to ramp up Britain’s battery production and infrastructure to boost the UK’s domestic battery supply chain.

Professor David Greenwood, CEO of the WMG High Value Manufacturing Catapult Centre said: “Cathode and anode active materials make up more than 50% of the value of an automotive battery cell.

of an automotive battery cell.

“For the UK to take its great academic research into production, and to capture the billions of pounds of resulting economic value in the UK, we need facilities which allow Britain to scale up and fully evaluate new materials. This investment, alongside the combined skillsets of CPI and WMG will provide that capability for the UK.”

The funds are specifically to help turbocharge the scale up of battery materials manufacturing within the UK. Only by producing batteries on a wider scale domestically can the EV industry make sure there is no bottleneck in supply and demand. By strengthening UK supply chains of battery materials, WMG is working with UKBIC and others to create a more resilient supply chain.

Thomas Bartlett, Challenge Deputy Director for the Faraday Battery Challenge, said: “AMBIC will bring together two emerging regions of battery innovation and manufacturing; the North-East and Midlands, under one facility to de-risk and accelerate battery materials scale up in the UK.

“Through the Faraday Battery Challenge’s £12m investment in the High Value Manufacturing Catapult we will establish a truly world-class facility to support the growth of a battery materials supply chain. With AMBIC and previous investments in cell, module and pack scale-up at UKBIC and R&D in the wider ecosystem, the UK will now be in a position to support businesses from “powder to pack” and from lab to commercial scales.”

Katherine Bennett, CEO of the High Value Manufacturing Catapult, said: “The next generation of battery technologies are critical to the green energy transition and a major opportunity for UK manufacturing. Realising that potential will require combining our collective expertise and this investment from the Faraday Battery Challenge is a brilliant example of that in action.

“In CPI and WMG, the Advanced Materials Battery Industrialisation Centre has two centres that are at the very forefront of chemical processing and battery cell development; together they can turbo charge battery materials scale-up.”

Frank Millar, Chief Executive Officer at CPI, said: “The Advanced Materials Batteries Industrialisation Centre will enhance the UK’s existing competitive advantages in batteries technology, and it stands to become a catalyst for the UK to address some of the biggest challenges we face as a nation. By giving innovators the opportunity to harness our expertise we can tackle issues such as climate change, while growing a sector that will be vital to the future of the economy.”

Members of the Slovakia government visit WMG

Delegates from the Slovakian government visited WMG, University of Warwick for an introduction into the department’s ground-breaking battery R&D and a discussion on the importance of industry and academia collaboration.

A total of eight delegates led by State Secretary, Ministry of Economy, Ján Oravec enjoyed a tour of the Energy Innovation Centre (EIC) by Chief Engineer, Mark Amor-Segan who demonstrated EIC’s facilities to research, develop and test the latest technologies at the forefront of energy storage.

Professor Paul Jennings, Director of Research at WMG, University of Warwick who hosted the visit said: “It was great to be able to meet the delegation and showcase the power of academia and industry working together, demonstrating how we are helping to drive the sector forward through impactful research and new education and skills offerings.”

Find out more about WMG’s energy research here: https://warwick.ac.uk/fac/sci/wmg/research/energy/

WMG launches EV battery recycling facility

WMG, at the University of Warwick, has revealed its new EV battery recycling scale-up facility, the first of its kind in the UK.

WMG, at the University of Warwick, has revealed its new EV battery recycling scale-up facility, the first of its kind in the UK.

The adoption of electric vehicles has created a huge demand for battery metals such as lithium, nickel and cobalt; and this will accelerate each year as electric vehicles replace conventional vehicles. UK-based OEMs pay hundreds to recycle end-of-life lithium-ion batteries that are then exported abroad for material recovery, with the material later repurchased. Recycling of batteries in the UK will provide a stable and sustainable supply of indigenously sourced metals that will be vital for the UK’s automotive needs.

Anwar Sattar, Lead Engineer at WMG, explains: ‘‘The UK has some of the best research organisations in the world, and this facility will now enable us, like our international peers, to take our innovations to the EV market direct.

like our international peers, to take our innovations to the EV market direct.

“We can now carry out kilogramme scale research which will allow us to attain data that is much more valuable to the UK industry, allowing them to make informed decisions about issues such as material handling and separation, scalability, product quality and waste production.’’

Professor David Greenwood, CEO of the WMG Centre HVM Catapult and Director of Industrial Engagement adds: “Batteries are a key enabler to the use of zero carbon energy, and they are a great industrial opportunity for the UK. Making them uses significant quantities of valuable materials, so it is essential that they are safely collected and recycled at the end of their useful life – providing the material feedstock for future generations of batteries. Today’s processes recover as little as 50% of the mass of the battery, and require large quantities of energy and chemicals as inputs. This new facility at WMG will allow us to research new recovery techniques which are more effective, cleaner and cheaper to operate.”

The new recycling facility, funded by the High Value Manufacturing Catapult, is situated within the Advanced Materials Manufacturing Centre. It is equipped with state-of-the-art equipment such as a wet alkaline scrubber which will enable researchers to safely carry out experiments that are not possible elsewhere. It is designed to accommodate pilot scale recycling machinery including dryers, furnaces, separators, and various reactors for the chemical recovery of metals. The facility will also host a scaled-up version of WMG’s novel lithium recovery process which will be able to recover over 90% of the lithium in a battery at very high purities.

The new recycling facility, funded by the High Value Manufacturing Catapult, is situated within the Advanced Materials Manufacturing Centre. It is equipped with state-of-the-art equipment such as a wet alkaline scrubber which will enable researchers to safely carry out experiments that are not possible elsewhere. It is designed to accommodate pilot scale recycling machinery including dryers, furnaces, separators, and various reactors for the chemical recovery of metals. The facility will also host a scaled-up version of WMG’s novel lithium recovery process which will be able to recover over 90% of the lithium in a battery at very high purities.

Various projects are already underway at the facility including an £8.9m project ‘Recycling of EV Cells from Obsolete Vehicles at Scale’ (RECOVAS). Supported by the Advanced Propulsion Centre, the project will create a circular supply chain for electric vehicle batteries in the UK.

Find out more about WMG’s battery research here: Energy (warwick.ac.uk)

UK-based consortium established to develop prototype solid-state batteries

MOU signed between Johnson Matthey, Faraday Institution, Britishvolt, Oxford University, UK Battery Industrialisation Centre, Emerson & Renwick and University of Warwick

HARWELL, UK (19 August 2021) A consortium of seven UK-based organisations has signed a memorandum of understanding to combine ambitions to develop world-leading prototype solid-state battery technology, targeting automotive applications.

develop world-leading prototype solid-state battery technology, targeting automotive applications.

Solid-state batteries offer significant potential advantages over conventional lithium-ion batteries and could be transformational in meeting the UK’s net zero commitments through the electrification of transport. The successful outcome of the collaboration would be to harness and industrialise UK academic capability to produce cells using highly scalable manufacturing techniques that leapfrog the cost-effectiveness and performance achieved elsewhere.

The consortium comprises the following world-leading organisations in battery research, development and manufacturing:

· Faraday Institution – the UK’s independent institute for electrochemical energy storage research, which has led the consortium’s formation and will lead its development.

· Britishvolt – the UK-based Gigaplant developer, with a site in NE England.

· E+R (Emerson & Renwick) – a world leading designer of manufacturing equipment.

· Johnson Matthey – a global leader in sustainable technologies and the UK’s leading battery materials business.

· Oxford University – that leads the Faraday Institution’s solid-state battery project (SOLBAT) and provides the necessary scientific understanding to the consortium.

· UK Battery Industrialisation Centre – the pioneering battery manufacturing development facility to enable UK battery manufacturing scale-up and facilitate upskilling in the battery sector.

· WMG, University of Warwick – leaders in battery R&D and initial scale-up capability, as well as academic and apprenticeship skills development.

The preliminary design for a prototyping facility has been developed. Sources of funding are currently being sought.

Minister for Investment Lord Grimstone said: “Collaboration between industry, government and our world-leading academic institutions is putting the UK at the forefront of global efforts to develop innovative automotive technologies, such as solid-state batteries.

the forefront of global efforts to develop innovative automotive technologies, such as solid-state batteries.

“It is the work of our internationally-renowned research and development base, like those brought together by this consortium, that will give us the tools needed to forge a strong and sustainable future for the automotive sector and increase our contribution to combatting climate change.”

“I am delighted to be able to announce the formation of this unique consortium for the advancement of solid-state battery prototyping that includes leading UK-based organisations at many stages in the value chain,” said Professor Pam Thomas, CEO of Faraday Institution. “Our leadership in this venture signals a move towards a role that the Faraday Institution will increasingly play as a trusted convener of significant partnerships between UK industry and academia as a route to commercialise breakthrough science emerging from our research programmes to maximise UK economic value.”

Solid-state batteries (SSBs) offer significant potential advantages over existing lithium-ion battery technologies, including the ability to hold more charge for a given volume (leading to increased electric vehicle (EV) range) and reduced costs of safety-management. Early deployment of SSBs is likely to be in consumer electronics, niche automotive applications and unmanned aerospace, before being used in broader EV markets. The Faraday Institution forecasts that, in 2030, SSBs are likely to take a 7% share of the global consumer electronics battery market and a 4% share of the EV battery market[1]. Global SSB revenues from sales to EV manufacturers are expected to reach $8 billion by 2030[2] and then grow rapidly to 2040 and 2050 when the market is expected to become extensive.

However, there are fundamental scientific challenges that need to be addressed before high power SSBs with commercially relevant performance can be realised. The Faraday Institution’s SOLBAT project has made considerable progress in addressing these challenges over the last three years.

However, there are fundamental scientific challenges that need to be addressed before high power SSBs with commercially relevant performance can be realised. The Faraday Institution’s SOLBAT project has made considerable progress in addressing these challenges over the last three years.

The construction of the one-of-a-kind facility being developed by the collaboration will enable SSB technology to emerge from UK university laboratories. It will allow larger cells to be produced using scalable manufacturing techniques that will be improved iteratively through deep investigation of the causes of problems that emerge during manufacture and testing of prototype batteries. This will leverage the collective knowledge of Faraday Institution SSB researchers and the industrial partners.

Christian Gunther, CEO, Battery Materials at Johnson Matthey comments, “The realisation of a prototype solid-state battery cell will be a great achievement for the UK battery industry, and this consortium will be a critical enabler for delivering this milestone. Delivering enhanced range and safety over traditional lithium-ion battery technologies will be a key driver for battery electric vehicle adoption, supporting the transition to a net zero future.”

Dr Allan Paterson, Chief Technology Officer, Britishvolt comments, “Solid-state is the holy grail of battery solutions. Solid-state batteries have the potential to increase energy density significantly over battery technology available today and could dramatically, and positively, change the world of electric vehicles. Britishvolt will be at the forefront of commercialising this step change over the coming years. This collaboration, which includes major global industrial leaders such as Johnson Matthey and academic leadership from University of Oxford, underscores another key objective in our technology roadmap – home grown intellectual property.”

Professor Peter Bruce, Principal Investigator of SOLBAT, comments: “It’s fantastic to see the culmination of combined UK academic strength in solid-state battery research come to fruition. I’m proud that the work of the Faraday Institution SOLBAT project, led by Oxford University, will make a significant contribution to the UK’s green energy revolution.”

Ian Whiting, Commercial Director at UKBIC added: “Our newly opened national battery manufacturing scale up facility is already contracted to scale new cells and battery packs by companies basing their manufacturing centres in the UK. It’s a really exciting time for this fast-growing industry. We’re scaling technologies that will be the core products of the UK’s emergent Gigafactories. But we need to think even further ahead and solid-state battery technology is going to be a big part of that. This collaboration is what is needed to give the UK the edge it needs in creating a centre of excellence for solid-state batteries and we’re excited to be part of it. The bringing together of academic and industrial know how in this space is key to unlocking Britain’s electrified potential.”

David Greenwood, Professor of Advanced Propulsion Systems, and CEO of WMG High Value Manufacturing Catapult comments: “Early forms of solid-state battery are already around us, but we have yet to see solutions which are both mass-manufacturable and meet the performance and cost targets for future transport applications. There remains huge opportunity for innovation in this space, and this initiative will provide the route for the UK to fast-track candidate technologies to industrialisation.”

Andrew C Jack, Sales Director, E&R Group comments, “E&R Group are delighted to be contributing our world renowned engineering expertise working in partnership Faraday and the wider consortium on this exciting development for next generation battery production for the UK.

For more information on the Faraday Institution, visit www.faraday.ac.uk and follow @FaradayInst on twitter.

Highly efficient grid-scale electricity storage at fifth of cost – researchers modify hybrid flow battery electrodes with nanomaterials

Researchers in WMG at the University of Warwick, in collaboration with Imperial College London, have found a way to enhance hybrid flow batteries and their commercial use. The new approach can store electricity in these batteries for very long durations for about a fifth the price of current technologies, with minimal location restraints and zero emissions.

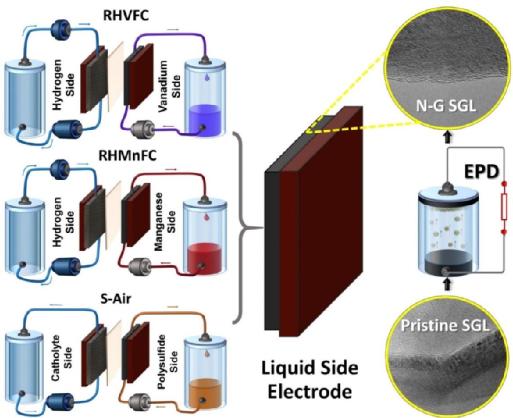

The researchers enhanced three hybrid flow cells using nitrogen doped graphene (exposed to nitrogen plasma) in a binder-free electrophoresis technique  (EPD)

(EPD)

Wind and solar power are increasingly popular sources for renewable energy. Unfortunately, intermittency issues keep them from connecting widely to the National grid. One potential solution to this problem involves in the deployment of long-duration battery technology, such as the redox flow battery. Despite its great promise the current costs of this system are a key determining factor to real-world adoption. An affordable grid battery should cost £75/kWh, according to the US Department of Energy. Lithium-ion batteries, which lead the charge for grid storage, cost about £130/kWh.

Now WMG researchers have found a way of enhancing hybrid flow batteries or regenerative fuel cell (RFC) technology that could store electricity for very long durations for about one-fifth the cost of current storage technologies, with flexibility in siting and with minimal environmental impact. The technology combines carbon-based electrodes with economically sourced electrolytes, (manganese or sulphur, which are abundant chemicals in the planet) by means of a simple and yet highly effective electrophoretic deposition of nano-carbon additives (nitrogen-doped graphene) that enhance the electrode durability and performance significantly in highly acidic or alkaline environments.

The researchers have published their findings in a paper entitled, ‘Hybrid Redox Flow Cells with Enhanced Electrochemical Performance via Binderless and Electrophoretically Deposited Nitrogen-Doped Graphene on Carbon Paper Electrodes’ in the December 2020 edition of the journal ACS Applied Materials & Interfaces.

Dr Barun Chakrabarti, a Research Fellow in WMG at the University of Warwick and one of the lead authors on the paper said:

“This EPD technique is not only simple but also improves the efficiencies of three different economical hybrid flow batteries thereby increasing their potential for widespread commercial adoption for grid-scale energy storage.”

The hybrid flow battery’s total chemical cost is about 1/30th the cost of competing batteries, such as lithium-ion systems. Scaled-up technologies may be used to store electricity from wind or solar power, for multiple days to entire seasons, for about £15 to £20 per kilowatt hour. These batteries are also extremely useful for grid-scale load levelling applications as their design is very flexible due to their unique feature of sizing their power independently of their energy.

The energy density of a hybrid flow battery, especially the polysulphide/air system (S-Air), is 500 times higher than pumped hydroelectric storage. It is also so much more compact and can be placed near any renewable generation.

ENDS

22 JANUARY 2021

Notes for Editors

High-res image available at:

https://warwick.ac.uk/services/communications/medialibrary/images/january_2021/barun_release_image.jpg

Caption: A Binder-Free Horizontal Electrophoretic Deposition (EPD) Process Is Used to Activate Commercial Carbon Paper Electrodes Using Nitrogen-Doped Graphene

Credit: WMG, University of Warwick

Full list of researchers: Co-investigators with Dr Chakrabarti at the WMG Energy Innovation Centre at the University of Warwick are: Evangelos Kalamaras (Project Engineer, Battery Testing) and Professor Jon Low (Associate Professor, Electrochemical Engineering). Co-investigators from Imperial include Anthony Kucernak and Nigel Brandon.

The full paper with all author details can be found here: Hybrid Redox Flow Cells with Enhanced Electrochemical Performance via Binderless and Electrophoretically Deposited Nitrogen-Doped Graphene on Carbon Paper Electrodes

Background history to this area of research

Development of the EPD technology began in 2013, when Professor Low joined WMG as an Assistant Professor and researched industrial Lithium-ion battery manufacturing processes. EPD involves the migration of electrically charged particles through a fluid that is under the influence of an electric field generated by applying the right potential.

Although EPD is an industrially adopted process such as for depositing industrial coatings onto conductive substrates, its mass-scale adoption for energy storage applications has only recently seen some success. Supported by EPSRC’s First Grant (EP/P026818/1, https://gtr.ukri.org/projects?ref=EP%2FP026818%2F1) and Industrial Strategy Challenge Fund on battery and supercapacitor manufacturing (EP/R023034/1, https://gtr.ukri.org/projects?ref=EP%2FR023034%2F1), Low’s research team have developed EPD for preparing lithium-ion battery electrodes that meet industrial standards for thickness and mass loadings and published their finding in ‘Batteries and Supercaps’ (https://chemistry-europe.onlinelibrary.wiley.com/doi/full/10.1002/batt.201900017). They have also produced carbon electrodes with nanomaterials for improving the practical performance of vanadium-based flow batteries using deep eutectic solvent electrolytes, and published their finding in ‘Batteries’ (https://www.mdpi.com/2313-0105/6/3/38).

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

The WMG Battery School is back, and it’s virtual!

The WMG Battery School, supported by the APC and HVM Catapult, will take place, from 14th to 18th September, for key industry personnel.

The WMG Battery School, supported by the APC and HVM Catapult, will take place, from 14th to 18th September, for key industry personnel.

WMG battery experts will facilitate a mix of live lectures and pre-recorded practical hands-on-sessions, virtually, over the five days.

The lectures will cover manufacturing Lithium batteries, module and pack design, electrical testing and ageing, battery management systems, safety and abuse testing, forensic characterisation and battery end of life.

Meanwhile the practical, pre-recorded in the Energy Innovation Centre, lab sessions, will focus on microscopy; electrode mixing and coating; pouch and cylindrical cell fabrication; cell and module testing; and forensics.

Find the full lecture and demo programme and register your interest here or by email: WMGShortCourses@warwick.ac.uk

Charging ahead at Battery School

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG is running a special three-day Battery School at its Energy Innovation Centre from 17-19 February 2020 for industry personnel.

WMG battery experts will facilitate a mix of lectures and practical hands-on-sessions, with the intention of inspiring the next generation of engineers into battery related careers, crucial for the UK’s electrification sector.

The lectures will cover areas including manufacturing Lithium batteries, module and pack design, electrical testing and ageing, battery management systems, safety and abuse testing, forensic characterisation and battery end of life.

Meanwhile the practical lab sessions will focus on microscopy; electrode mixing and coating; pouch and cylindrical cell fabrication; cell and module testing; and forensics.

Find out more and book your place here.

Used electric vehicle batteries could be used for rickshaws in Bangladesh

Used EV batteries could be used to power rickshaws in Bangladesh, as researchers from WMG, University of Warwick, seek to find out how they can be repurposed for the rickshaws and lower peoples’ carbon footprint.

Motorised rickshaws, also known as easy-bikes, have gained popularity in Bangladesh due to their cost-effectiveness with one million of them all over the country.

However, the easy-bike currently uses a lead-acid battery for power, which has a lifetime of 6-12 months and therefore increases the operating cost as well as the carbon footprint.

In order to reduce the carbon footprint, researchers at WMG are exploring the possibility of repurposing used EV Li-ion batteries thanks to a £25,000 grant from Global Challenges Research Fund (GCRF), an award from the UKRI aimed to deliver scalable solutions to issues faced by low and middle-income countries.

Currently, Li-ion batteries retire from EVs after reaching 70-80% of their state of health (SoH). At 70% SoH, the lithium-ion battery still have 3 times higher energy density than a new lead-acid battery, and potentially can have a lifetime of 3-5 years in easy-bike application.

The researchers hope to repurpose the batteries to improve the energy storage life from 6-12 months to 3-5 years, which in turn will reduce the number of batteries being recycled and improve the ecosystem.

The new application of Li-ion batteries will be better environmentally without an additional cost in transport. As easy-bike replaces manual driving, the quality of life will improve significantly and bring a socio-economic change to a large community in Bangladesh. Furthermore, this development could reduce the consumption of grid-connected electricity which could be used to develop industries and infrastructure.

In fact, there are currently one million rickshaw pullers in Bangladesh who earn $4.8 billion every year. The new development in easy-bikes will directly improve their economic status. A few million people involved in vehicle support such as mechanics and manufacturing industries will also be benefited.

This project eventually could lead to mass production of second-life Li-ion batteries in Bangladesh, in conjunction with UK automobile industries, which will create job opportunities for thousands of people.

Dr Mohammad Al-Amin from WMG, University of Warwick comments:

Dr Mohammad Al-Amin from WMG, University of Warwick comments:

“To prevent climate change, all cars in the future will need to be electric. However, the batteries in EVs once they have reached their end of life, for car purposes, is something that can be explored more, as there is still energy left in them to be used.”

“If we can re-purpose them to be used for easy-bikes in Bangladesh it will help lower their carbon footprint and provide the country with a new economy. Thousands of jobs opportunities could be created both in Bangladesh and the UK.”

ENDS

13 NOVEMBER 2019

NOTES TO EDITORS

High-res images available at: https://warwick.ac.uk/services/communications/medialibrary/images/october2019/mohammad_photograph.jpg

About GCRF - https://www.ukri.org/research/global-challenges-research-fund/

UK Research and Innovation works in partnership with universities, research organisations, businesses, charities, and government to create the best possible environment for research and innovation to flourish. We aim to maximise the contribution of each of our component parts, working individually and collectively. We work with our many partners to benefit everyone through knowledge, talent and ideas.

Operating across the whole of the UK with a combined budget of more than £7 billion, UK Research and Innovation brings together the seven research councils, Innovate UK and Research England.

FOR FURTHER INFORMATION PLEASE CONTACT:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

‘Nextrode’ project to revolutionise the manufacturing of battery electrodes

· Nextrode project could revolutionise the way electrodes for Li-ion EV batteries are manufactured

· Smart high performance electrodes could enable EVs to travel further and be more durable

· WMG at the University of Warwick will research and model new and existing manufacturing processes to unlock full potential of electrochemical materials in cells

The Faraday Institution funded “Nextrode” project, involving WMG at the University of Warwick, will research ways to make electrodes for Li-ion batteries which unlock the electrochemical potential of their ingredients.

WMG, at the University of Warwick, is one of six university partners in the Nextrode project, which is led by the University of Oxford, alongside six industry partners – including the UK Battery Industrialisation Centre (UKBIC) who will be researching how to make electrodes for Li-ion Electric Vehicle batteries more efficiently.

Today’s Li-ion batteries are made using a 'slurry casting' process, whereby the active materials are mixed in a wet slurry and coated onto thin foils of aluminium or copper, then dried and compressed. This process is highly effective for mass production, but is developed empirically through trial and error, at great cost to the manufacturer.

In this project, WMG will gain greater depth of knowledge in that process with a view to being able to predictively model and optimise it, so that future electrodes can be cheaper, store more energy, and get to market faster. To do this, WMG will use their state-of-the-art “battery scale up” facility, as well as taking data from the UKBIC when it opens next year.

Furthermore, slurry cast electrodes limit the performance of the battery as the active electrochemical materials are uniformly distributed throughout the electrode structure. Research has shown that arranging the materials in a structured way can dramatically improve battery performance, but at present there is no mass-manufacturing route to do so. This project will investigate new manufacturing methods to create structured electrodes in a cost effective way at high manufacturing volumes.

Professor David Greenwood from WMG, University of Warwick comments:

Professor David Greenwood from WMG, University of Warwick comments:

“Battery manufacturing is a critical industry for the UK to grow. It is highly competitive, and to win, we will need excellence in both science and manufacturing. The Nextrode project brings these two elements together to make future Li-ion batteries for Electric vehicles more energy efficient and affordable. Our unique research facilities are key to acquiring the knowledge required to deliver a step change in industrial capability."

Professor Patrick Grant from Oxford University who will lead project comments:

“Nextrode aims to strengthen the scientific understanding of existing electrode manufacturing so we can make it more flexible and extract further performance gains, but we will also develop a new generation of manufacturing approaches for ‘smart” electrodes where the different electrode materials are arranged with greater precision and provide even greater performance benefits. We anticipate these benefits could be realised for almost any type of battery chemistry”.

This project is just one of five that the Faraday Institution has announced today, 4th September. In total, it will award up to £55 million to five UK-based consortia to conduct application-inspired research over the next four years to make step changes in the understanding of battery chemistries, systems and manufacturing methods.

Business Minister, Nadhim Zahawi comments:

“Today’s funding backs scientists and innovators to collaborate on projects that will deliver a brighter, cleaner future on our roads. We are committed to ensuring that the UK is at the forefront of developing the battery technologies needed to achieve our aim for all cars and vans to be effectively zero emission by 2040.”

Neil Morris, CEO of the Faraday Institution comments:

“It is imperative that the UK takes a lead role in increasing the efficiency of energy storage as the world moves towards low carbon economies and seeks to switch to clean methods of energy production. Improvements in EV cost, range and longevity are desired by existing EV owners and those consumers looking to purchase an EV as their next or subsequent car. Our research to improve this web of battery performance indicators (which are different for different sectors) are being researched, with a sense of urgency, by the Faraday Institution and its academic and industrial partners. Our fundamental research programmes are putting the UK at the forefront of this disruptive societal, environmental and economic change.”

UK Research and Innovation Chief Executive, Professor Sir Mark Walport, comments:

“Bringing together experts across industry and academia, this exciting research will grow our understanding of battery chemistries and manufacturing methods, with the potential to significantly improve the UK’s ability to develop the high-performance electric vehicles of the future.

ENDS

4 SEPTEMBER 2019

Notes to Editors

Full list of Institutions include:

University of Birmingham

University College London

University of Oxford

University of Sheffield

University of Southampton

University of Warwick

For further information about the Faraday Institution visit: https://faraday.ac.uk/

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 2476 574 255 or +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

Charging ahead at Battery School

PhD students, and future battery engineers, from leading universities across the UK joined us for a special week-long Battery School at our Energy Innovation Centre, for the Faraday Institution, recently.

In our role as the Electrical Energy Storage APC Spoke, our battery experts facilitated a mix of lectures and practical sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

In our role as the Electrical Energy Storage APC Spoke, our battery experts facilitated a mix of lectures and practical sessions covering electrochemistry, applications, future technologies, manufacturing, safety, testing, forensics and battery end of life.

Fran Long, Education and Training Co-ordinator, at The Faraday Institution, said: “The WMG Battery School, at the University of Warwick, gave our PhD students a wonderful week of detailed theory and practice with an abundance of high quality lectures and ‘hands-on’ lab sessions.

“We would like to thank all of the WMG staff involved in making this such a valuable experience for the students. Encouraging the next generation of engineers into battery related careers, is extremely important for the UK’s electrification sector.”

The Faraday Institution is the UK’s independent institute for electrochemical energy storage science and technology, supporting research, training, and analysis. It brings together scientists and industry partners on research projects to reduce battery cost, weight, and volume; to improve performance and reliability; and to develop whole-life strategies from mining to recycling to second use.

The Battery School is part of the Faraday Battery Challenge, along with the UK Battery Industrialisation Centre (of which WMG was part of the winning consortium).

Find out more about our Energy Innovation Centre here.